ECI is one of the independent businesses in the Emerson Impact Partner Network. They are the industrial automation and process control partner for manufacturers and producers in the United States’ western Pennsylvania, West Virginia, western Maryland, and Ohio regions.

ECI’s Brian Weaver wrote The Cost of Hazardous Occupational Noise & Benefits of New Noise Reduction Technologies. Brian opens the piece with the challenges manufacturers and producers face with noisy environments and cites these statistics:

ECI’s Brian Weaver wrote The Cost of Hazardous Occupational Noise & Benefits of New Noise Reduction Technologies. Brian opens the piece with the challenges manufacturers and producers face with noisy environments and cites these statistics:

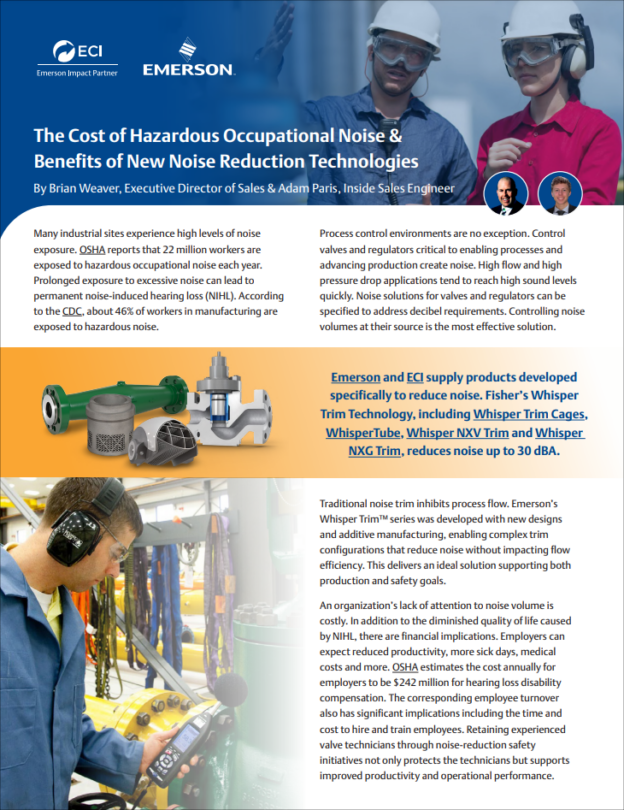

OSHA reports that 22 million workers are exposed to hazardous occupational noise each year. Prolonged exposure to excessive noise can lead to permanent noise-induced hearing loss (NIHL). According to the CDC, about 46% of workers in manufacturing are exposed to hazardous noise.

Not successfully reducing the noise levels can affect employees and company financials.

In addition to the diminished quality of life caused by NIHL, there are financial implications. Employers can expect reduced productivity, more sick days, medical costs and more. OSHA estimates the cost annually for employers to be $242 million for hearing loss disability compensation. The corresponding employee turnover also has significant implications including the time and cost to hire and train employees. Retaining experienced valve technicians through noise-reduction safety initiatives not only protects the technicians but supports improved productivity and operational performance.

In process manufacturing operations, high:

…flow and high pressure drop applications tend to reach high sound levels quickly. Noise solutions for valves and regulators can be specified to address decibel requirements.

As an Emerson Impact Partner, ECI supplies many Emerson brands, including the Fisher brand flow control technology and solutions. Fisher Whisper Trim technology, including Whisper Trim Cages, WhisperTube, Whisper NXV Trim, and Whisper NXG Trim, reduces noise up to 30 dBA.

Brian explains that the WhisperTrim series:

…was developed with new designs and additive manufacturing, enabling complex trim configurations that reduce noise without impacting flow efficiency. This delivers an ideal solution supporting both production and safety goals.

Read the piece for more on noise exposure limits, and follow the links above for more on the acoustic attenuation capabilities in the Fisher Whisper Trim series of products.