We want to operate our centrifugal compressors as efficiently as possible, yet we need to avoid the destructive possibilities that surge conditions can bring.

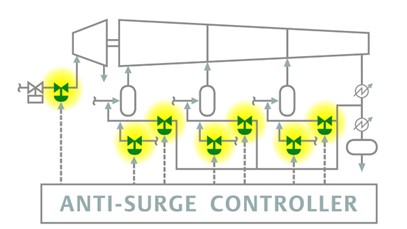

It’s essential to have real-time compressor performance maps to understand how close the compressor operates to the surge line. An anti-surge controller based on a model incorporating adaptive tuning, which modulates the recycle valve, can accommodate changing conditions such as gas composition and ambient temperature.

Optimized Fisher Anti-Surge Valve assemblies with FIELDVUE DVC7K digital valve controllers are well-suited for recycling discharge gas to the compressor inlet to move away from surge conditions.

Optimized Fisher Anti-Surge Valve assemblies with FIELDVUE DVC7K digital valve controllers are well-suited for recycling discharge gas to the compressor inlet to move away from surge conditions.

I caught up with prolific author Greg McMillan, who stressed the importance of control valve response times and resolutions, such as the valves highlighted above, coupled with the digital valve controllers (DVCs) for precise, responsive control actions. Using volume boosters instead of DVCs can introduce additional problems.

A PID-based control strategy can manage surge margin by using feedforward signals from flow, pressure, or compressor speed fluctuations. The PID loop tracks the distance to the surge curve to fine-tune the response to avoid inefficiencies for unnecessary recycling.

This surge margin, often expressed as a percentage, indicates how far the current operating conditions are from the surge curve on its performance map. For example, a 5% surge margin means the compressor operates at a flow rate that is 5% higher than the surge flow conditions.

It is essential that the performance accurately reflects the actual compressor performance rather than the nameplate performance at the time of installation. The surge line and performance map must be precise and updated regularly, as wear, fouling, or changes in gas composition can shift the surge point.

Feedforward control anticipates disturbances that could push the compressor toward surge, such as sudden changes in downstream demand, suction pressure, or compressor speed. Key process variables, including inlet flow, discharge pressure, and speed, are monitored, and their rates of change are used to predict potential surge risks.

Highly accurate measurement devices, such as Rosemount pressure and flow instruments, are critical in this application.

Greg noted that you must be careful with feedforward control and have logic to determine whether the surge valve action is necessary based on the proximity of the operating point to the surge setpoint and surge curve. Some applications have recycle valves that are typically partially open and must be incorporated into the logic.

I asked Greg to review what I had written, and he added these excellent insights.

The surge controller setpoint should be offset to the right of the surge curve on the compressor map so that the surge setpoint follows the shape of the surge curve, enabling the margin to be optimized to be on the longitudinal axis of the efficiency ellipses. The margin size depends on the speed of the automation system, the tuning of the surge controller, and the disturbance speed.

Even a fast feedback controller is unable to get a compressor out of severe surge because of the huge jumps in flow. What is needed is an open-loop backup that forces the surge valves to immediately open and holds them open for a sufficient time to sustain operating point stability before allowing the feedback controller to start to close the surge valves. The open-loop backup is triggered by a large predicted overshoot of the surge setpoint to prevent surge, or a precipitous drop in flow indicating an actual surge.

An innovation uses a predicted overshoot via a fast future value that is generated by the rate of change of a decreasing flow, with a good signal-to-noise ratio multiplied by the total loop dead time, with updates every controller execution. The open-loop backup simply puts the feedback controller into a remote output mode that is seen by operators.

The remote output is immediately stepped up to a position that typically prevents surge, but is incremented every execution until the future value stabilizes, putting the surge controller bumplessly back in cascade with the surge setpoint computed to sustain an offset from the surge curve. This DeltaV configuration is simple and easy to understand and optimize. Many suppliers of standalone compressor controllers have proprietary control strategies providing feedback control, with a backup requiring special expertise and tuning.

External-reset feedback (ERF), also known as dynamic reset limit, in the surge controller, with a fast readback of actual valve position, enables up and down setpoint rate limits in the analog output blocks to provide fast opening and slow closing of the surge valves without the need to retune the surge controller.

The surge control system principles basically are the same for surge vent valves and surge recycle valves. At least two valves in parallel are used to provide redundancy, particularly because surge valves might not open after sustained operation in closed position, where stiction from seal or seat friction is greatest. For multiple stages, there generally are recycle surge valves and a compressor surge control system for each stage. Ratio dividing may be used to proportion the different pressure rises for each stage.

Feedforward action is used to deal with the fast closing of user valves. What may seem to be a slow enough closing of a user valve can be troublesome because of the quick opening characteristic of on-off valves triggered by safety instrumented systems, where nearly all of the flow change occurs within 10% of closed position.

For more of the latest knowledge on smarter compressor surge control see the Control Global feature article “Compressor surge control: Deeper understanding, simulation can eliminate instabilities”.

Make sure to visit my earlier post, Centrifugal and Axial Compressor Control – Freely Available Educational Resource, to download your free copy of Greg’s book that can help you master these advanced techniques and more in operating your centrifugal and axial compressors safely and efficiently.