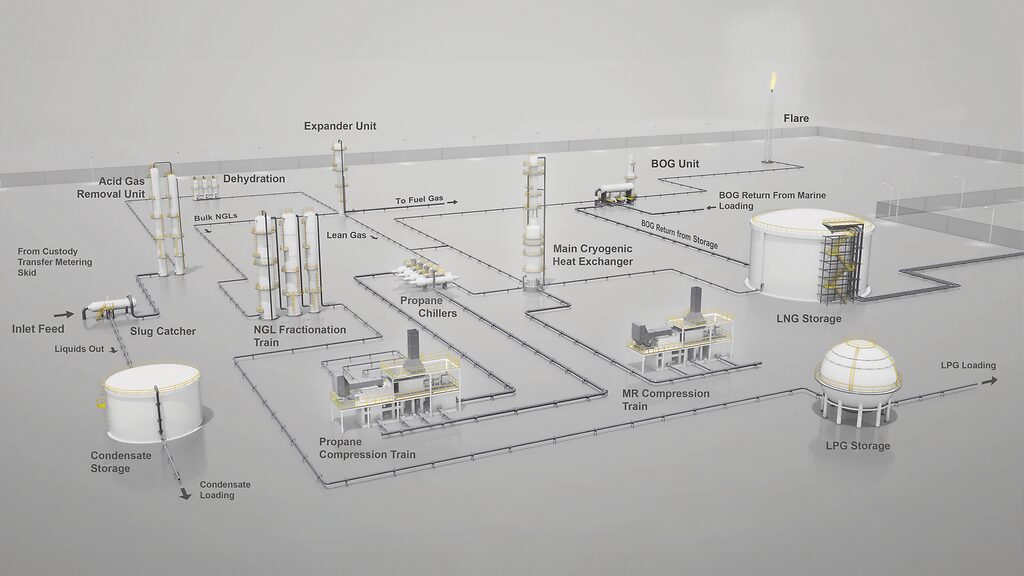

Over the past several years, liquefied natural gas (LNG) shipments worldwide have established a truly global market for natural gas. It’s a fascinating process to take natural gas, separate out any liquid condensates, dry the gas, and cryogenically cool the gas into the liquid phase. The LNG is loaded for transportation on ships to its destination for regasification into the gas phase.

The valves, regulators, and actuators involved in the various process steps are specialized to handle the pressures and temperatures. I came across an educational page on Emerson.com, Valves, Actuators, and Regulators for the Entire LNG Value Chain.

Selecting the proper final elements—valves, regulators, actuators—helps to enhance equipment reliability and improve LNG and regasification plants’ safety—ultimately driving cost savings and operational excellence.

This page highlights the key processes and suggests final element solutions in LNG and regasification plants, including:

- Inlet feed and separation

- Acid gas removal and dehydration

- Sulfur recovery

- Fractionation

- Main cryogenic heat exchanger

- Compression train

- LNG storage, jetty loading, and boil-off gas (BOG)

- Unloading, storage, and regasification

For example, in the main cryogenic heat exchanger, the recommended valves to size include a Fisher Joule-Thomson (JT) valve, a Vanessa triple-offset valve with cryogenic configuration, and a Fisher LNG temperature valve.

We discussed the importance of the JT valve in an earlier podcast, Unlocking LNG Success: How a Fisher JT Valve Supercharged a Main Cryogenic Heat Exchanger Podcast. In the post containing this podcast with Emerson’s Reid Youngdahl, I explained:

JT control valves reduce the pressure of the fluid significantly and induce the desired cooling. Because of the elevated pressure drop, the control valve can experience excessive noise levels if not addressed properly. It also experiences very low process temperatures and must be capable of precise throttling down to full cryogenic temperatures.

Visit the LNG Value Chain page to learn more about the recommended valves for the different applications and several real-world success stories across the LNG lifecycle, from planning to commissioning and startup through ongoing operations.