Emerson’s Bruce Greenwald, Christian Berg, and David Gray collaborated to present “Solutions for Advanced Therapeutics” at the Emerson Exchange 2025 Conference. Here is their presentation abstract.

ATMPs hold incredible potential to treat and cure life-threatening diseases, but managing the complex operations required for these therapies presents unique challenges. From precise control of patient-specific materials to near real-time product release, the demands on ATMP manufacturers are high. Gain insight into how Emerson’s comprehensive ecosystem of solutions supports ATMP operations across the entire product lifecycle. Learn about key approaches and technologies that enable manufacturers to consistently deliver high-quality therapies quickly and efficiently.

Advanced therapy medicinal products (ATMPs) include innovations such as gene therapies, cell therapies, and tissue engineering.

Bruce kicked off the session by focusing on Emerson’s 5 key value drivers for our customers – pipeline acceleration, flexible manufacturing, operational integrity, real-time release, and sustainable operations.

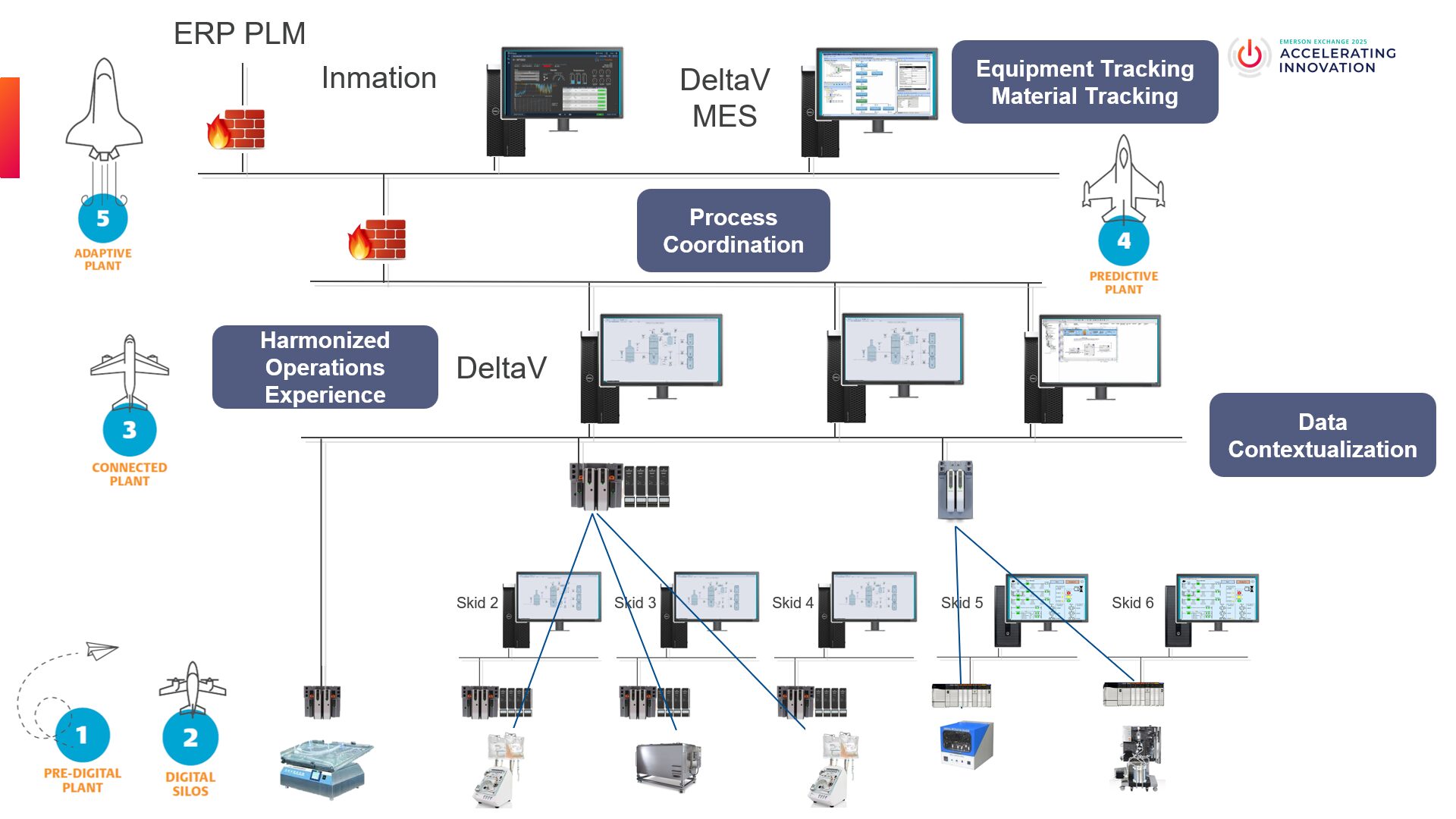

ATMP therapies have high product specificity and pace of innovation that require rapid information flows and context. The Biophorum organization has developed the Digital Plant Maturity Model to assess the current level of digital maturity among biopharmaceutical manufacturers across five key levels. Given the growing manufacturing challenges, attaining level is becoming the table stakes for companies.

As manufacturers transition from population-based therapies to disease-specific or patient-specific therapies, they must move to levels 4 and 5 of the Maturity Model to remain competitive in the marketplace. Emerson offers a portfolio of solutions to help organizations advance to higher levels of digital maturity.

Technologies to help move to level 4 include Digital Twin, DeltaV Mimic, DeltaV Quality Review Manager, DeltaV Recipe Exchange, DeltaV Training and Development, DeltaV Real-time Scheduling, and the Inmation industrial data fabric.

Technologies supporting the move to the highest level of digital maturity include Ballroom, Module Type Package (MTP), DeltaV Edge Environment, and DeltaV Recipe Transfer Management.

Christian discussed how today’s automation is vertically and horizontally siloed, creating pockets of data and expertise. An advanced industrial technology paradigm includes a secure-by-design and extensible software-defined architecture that is data-centric and spans the enterprise.

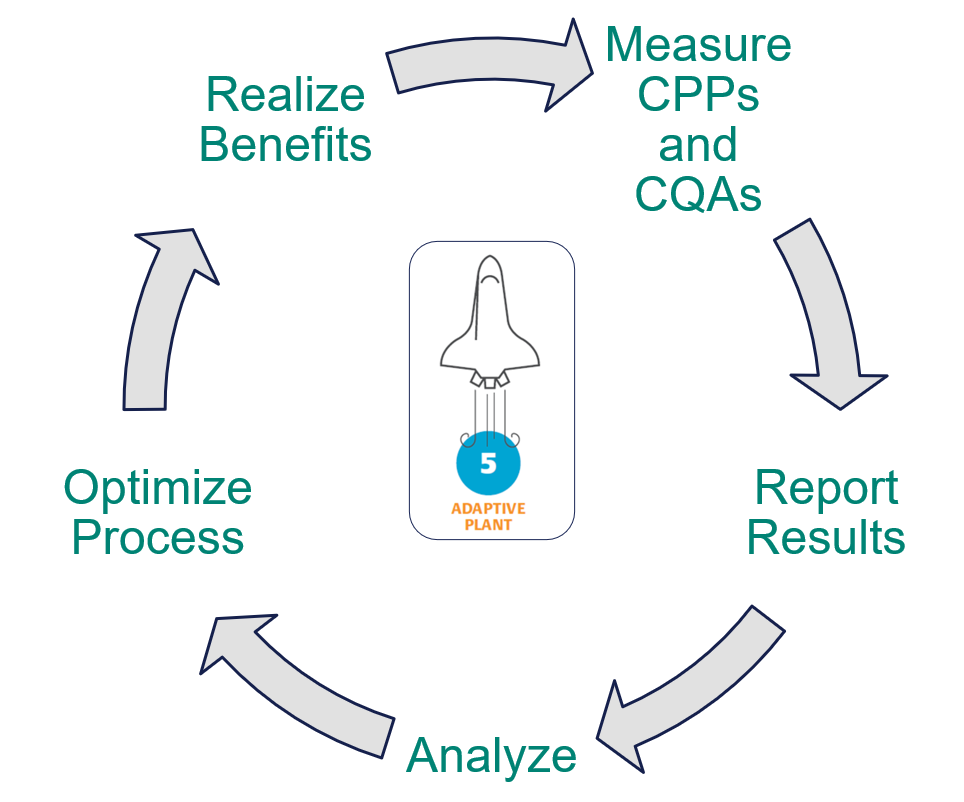

It’s essential to leverage technology to optimize the delivery of physical goods and services. This optimization can be distilled down to three fundamental performance measurements: lead time, productivity, and cost. With electronic batch records (eBR) and review by exception, it’s easy to draw those connections as we pursue the technological pieces that will ultimately bring our facilities closer to level 5, the Adaptive Plant.

The Adaptive Plant enables us to close the loop through automated process control, rapid product release, and ongoing, real-time process improvement. This all results in minimized product lead time, maximum productivity, and optimized cost. The Adaptive Plant is only possible with complete, accessible, contextualized data that an ecosystem of technologies can readily leverage.

Much of this is enabled by a modern approach to the IT infrastructure that bridges the plant control network with the operations management network and business solutions. This approach preserves plant security while allowing for process data egress, with complete context, while minimizing the burden of physical IT equipment.

Once the data is available, opportunities for analysis and optimization become unrestricted, and organizations can benefit from a global approach to process management, analysis, and optimization.

A modular manufacturing execution system (MES) approach decouples operations management functions from legacy data silos, providing flexibility in MES deployment strategies. This enables organizations to select the IT infrastructure that best suits their needs while maintaining system security and data integrity.

Christian closed by explaining that data-driven optimization requires a closed-loop connection to the value stream, and a data-centric architecture is key to the personalized healthcare revolution.

Visit the Life Sciences and Medical section on Emerson.com for more information on solutions designed to drive business performance improvements for pharmaceutical and biopharmaceutical manufacturers.