Industrial manufacturing automation technologies have long been perceived as lagging the technologies available for commercial and consumer applications. This situation was largely by design because mission-critical production demanded proven performance, as opposed...

clean-in-place

The Advantages of Digitalization in Clean-in-Place Systems

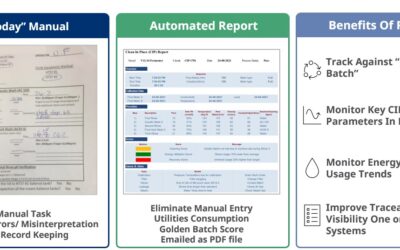

Clean-in-place (CIP) systems are a vital part of daily production in the food and beverage industry. They allow manufacturers to clean internal piping, tanks, and machines from one batch to the next to meet government regulations and ensure product quality and safety. However, CIP operations also represent a significant portion of a facility’s total utility costs and often involve manual process adjustments and manual data recording.

Reduce Waste & Increase Efficiency in Clean-in-Place Processes

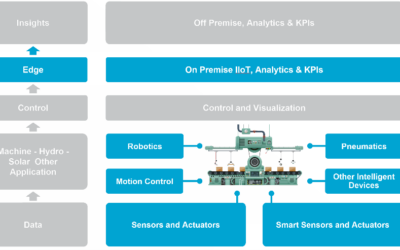

While the idea of adding costs to a food and beverage or pharmaceutical industry process like Clean-in-Place/Steam-in-Place (CIP/SIP) has not traditionally been an easy decision, in today’s industrial environment that has changed. With the retirement of experts, the...

Keep Up to Date With the Latest News and Updates

Follow Us

We invite you to follow us on Facebook, LinkedIn, Twitter and YouTube to stay up to date on the latest news, events and innovations that will help you face and solve your toughest challenges.

Do you want to reuse or translate content?

Just post a link to the entry and send us a quick note so we can share your work. Thank you very much.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.