For a refinery, the efficiency and reliability of the fuel blending operations largely determines its overall financial performance. These fuels, including gasoline, diesel, fuel oils, jet fuel, and kerosene require the right blend of fuel components and additives...

inline blend

Optimized and Flexible Refinery Blending for Current Market Conditions

Refinery blending operations are the "cash registers" since it "…is the last chance to optimize the final saleable product, as well as the final opportunity to achieve as close to product specifications as possible." A recent RBN Energy blog post, The Price You Pay...

Improved Refinery Performance via Direct to Ship Blending

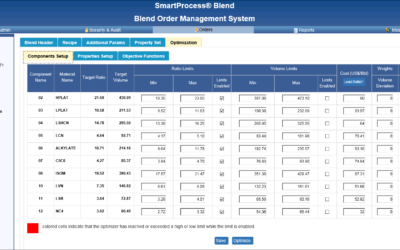

For refineries, blending operations can be challenging due to unscheduled downtime, off-spec production requiring reblending operations and quality giveaways by exceeding specifications. I caught up with Emerson’s Marcelo Carugo who noted that poor recipe management...

Increasing Refinery Flexibility to Handle Wide-Ranging Feedstocks

The complexity in crude oil refining has grown due to many factors including mix of crude oil feedstocks, government regulations, and increasingly global customer base for refined product. In a Hydrocarbon Processing article, Improve refinery flexibility and...

Keep Up to Date With the Latest News and Updates

Follow Us

We invite you to follow us on Facebook, LinkedIn, Twitter and YouTube to stay up to date on the latest news, events and innovations that will help you face and solve your toughest challenges.

Do you want to reuse or translate content?

Just post a link to the entry and send us a quick note so we can share your work. Thank you very much.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.