Les technologies de surveillance de l’état des équipements sont essentielles dans les industries de process car elles permettent d’identifier les problèmes qui se développent dans les équipements avant qu’ils n’entraînent une panne nécessitant une réparation ou un remplacement coûteux et pouvant avoir un impact sur la production.

Plantweb Optics

Anlagenzustandsüberwachung und Anlagendatenanalyse optimieren die Verfügbarkeit und Effizienz von Anlagen

Technologien zur Überwachung des Anlagenzustands sind in der Prozessindustrie unerlässlich, da sie zur Identifizierung sich entwickelnder Probleme in Anlagenkomponenten beitragen, bevor diese zu einem Ausfall mit kostspieligen Reparaturen oder Auswechslungen führen und möglicherweise die Produktion beeinträchtigen.

Il monitoraggio dello stato degli asset e l’analisi dei dati aiutano a massimizzare il tempo di disponibilità e l’efficienza degli impianti

Le tecnologie di monitoraggio dello stato degli asset sono vitali nelle industrie di processo perché aiutano a identificare qualsiasi problema in via di sviluppo negli asset prima che portino a un guasto che richiede costose riparazioni o sostituzioni e che potrebbe avere un impatto sulla produzione.

Maximizar el tiempo de actividad y la eficiencia de la planta a través de la monitorización de la condición de activos y el análisis de datos

Las tecnologías de monitorización de la condición de los activos son vitales en las industrias de procesos porque ayudan a identificar cualquier problema incipiente en el equipo antes de que provoque un fallo que requiera reparaciones o reemplazos costosos y que posiblemente afecten a la producción.

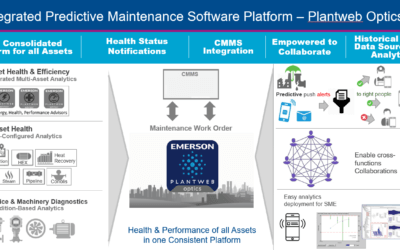

Asset health monitoring and data analysis help maximise plant uptime and efficiency

Asset health monitoring technologies are vital in the process industries because they help to identify any developing issues in equipment before they lead to a failure requiring costly repair or replacement and possibly impacting production. However, when a problem arises with a critical asset, organisations may have to comb through vast amounts of data from these monitoring technologies to diagnose the fault.

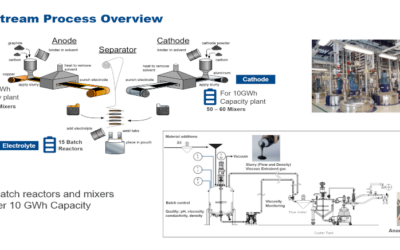

Improving Production, Safety and Reliability in Midstream Lithium Production

One of the challenges expressed by lithium battery manufacturers is that they have to be fast and agile because each of their customers may have different formulations for the cathode, anode, and electrolyte material.

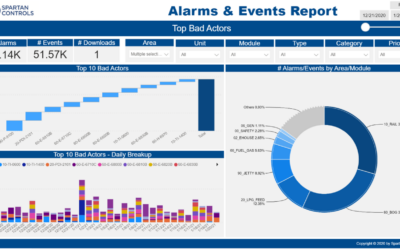

Process Alarm and Event Data in Non-Traditional Cloud-Based Applications

Plant network load balancing, cybersecurity, single-port firewall traversals, and other networking, data transport and storage challenges have constrained organizations in the ability to access these data sets at the scale desired. Growing volumes of data from operating plants is finding its way to enterprise IT networks including cloud platforms and is being leveraged in large numbers of use cases.

Industrial Software Enables Performance Gains

The 18th edition of Innovations in Process Automation from the Emerson European team is now available. It highlights some prime examples of Emerson’s industrial software capabilities and explains how these capabilities are helping manufacturers and producers to achieve significant performance gains.

Healthy Master Data Foundation for Digital Transformation

In this quick 2:40 YouTube video, Master Data Management and the Importance of Healthy Data, Emerson’s Curtis Thompson explains why having healthy data matters, and how to know if you have healthy data.

Operational Analytics in Digital Transformation

Podcast host Jim Cahill is joined by Emerson’s Michael Tworzydlo to discuss the role of operational analytics to ensure operational health and optimize plant-wide performance by detecting abnormal behavior of processes and assets, identify root causes of problems, and predict future performance.

Evolution of Predictive Maintenance through Enterprise Software

The asset health parameters across the plant can now be collected, stored, and fed real time into software algorithms. The software then processes and analyzes the data, turns it into actionable insights accessed by maintenance engineers. Depending on the criticality can be passed on for further processing and approvals, through desktops and mobile devices.

Unifying Operations Data in Support of Digital Transformation

An Amazon Web Services (AWS) article, Building an Industrial Data Platform on AWS with Emerson’s Plantweb Optics Data Lake, highlights how bringing these silos of operational technology (OT) data sources together enables holistic analysis of data across the enterprise.

Keep Up to Date With the Latest News and Updates

Follow Us

We invite you to follow us on Facebook, LinkedIn, Twitter and YouTube to stay up to date on the latest news, events and innovations that will help you face and solve your toughest challenges.

Do you want to reuse or translate content?

Just post a link to the entry and send us a quick note so we can share your work. Thank you very much.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.