Emerson South Korea general manager, Patrick Deruytter was in Austin recently. You may recall Patrick from earlier posts about large FPSO projects being performed there. He has an upcoming presentation at FLNG Project Advancement on accelerating FLNG (floating liquefied natural gas) project delivery using a main automation contractor approach.

For those unfamiliar with FLNG, it borrows the idea of floating production, storage and offloading by building a liquefied natural gas facility on a tank ship. From Wikipedia:

LNG is principally used for transporting natural gas to markets, where it is regasified and distributed as pipeline natural gas.

According to a World FLNG Market Report:

The IEA [International Energy Agency] forecasts annual growth in natural gas supply will average 1.6% from 2006 to 2030. By 2030, natural gas will account for 23% of total worldwide primary energy supply. The difficulties in progressing onshore projects in LNG has driven the adoption of FLNG which now offers an increasingly important method of bringing gas from stranded reserves to the market.

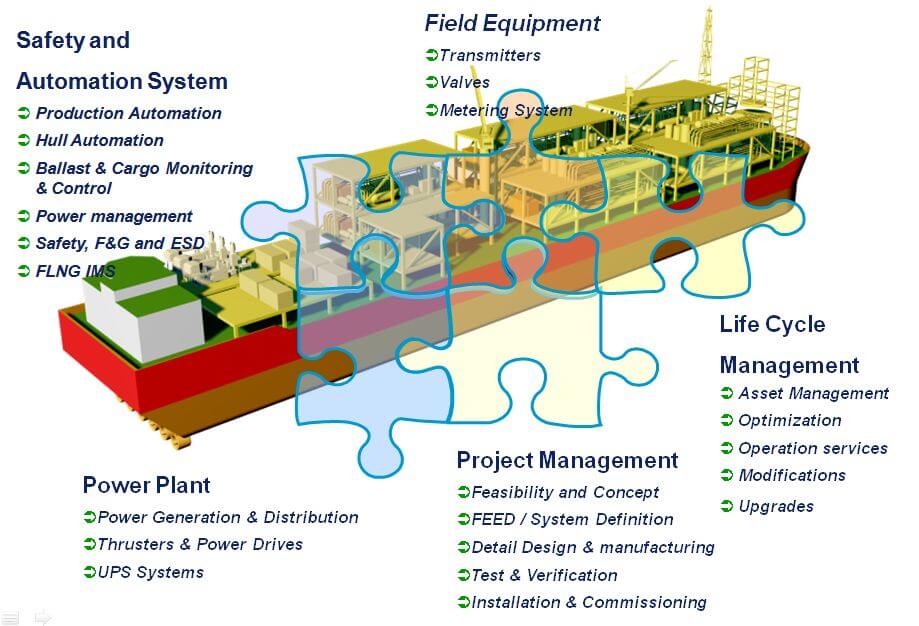

I saw an advanced copy of Patrick’s presentation. In it, he notes that process automation touches every element of an FLNG vessel including production units, hull, ballast, power generation and distribution, fire and safety systems, and information management systems (IMS).

Automation typically accounts for only 3% of the capital costs for an FLNG project, but is critical to its successful operation. The automation technology and project execution methodology play a large role in determining how successful ongoing operations will be.

The Construction Industry Institute (CII) described a PEpC (Procurement, Engineering, procurement and Construction) process that can produce:

…savings in time between 10 and 15 percent and savings in total project labor cost between 4 and 8 percent were possible.

CII describes how the PEpC process does this:

…utilize supplier expertise in all phases of the project life cycle by developing an advance procurement strategy and reaching agreement with suppliers on strategic procurement items and/or systems prior to the associated project engineering activities.

Patrick described how this process works on FLNG processes. Working as a main automation contractor (MAC), his team helps develop the execution plan and schedule, procurement specifications, design and execution specifications, device communication protocols, power/heat/loading estimations, measurement technologies, and role/responsibility matrices–all in the front end engineering design (FEED) phase of the project.

Post-FEED, the team develops cost estimates, clarifies scope of MAC supply for the engineering and procurement construction (EPC) contractors, and develops control system detailed design and integrated tests for long lead-time equipment such as compressors and tank storage.

He describes the role automation technology can play. A distributed modular approach for the automation reduces control room footprint, reduces cable size and weight, and facilitates modular design, pre-assembly and test which helps reduce the project timeline. Wireless instrumentation can reduce the project tasks required by eliminating power and grounding efforts, I/O and cabinet design, installation, and commissioning.

Also, electronic marshalling reduces design, engineering, drawings, cabinets and the associated incremental installation and commissioning effort required.

These technologies combined with a structured project execution methodology help to reduce the overall project risk and cost. It also provides the vessel’s staff with the control, safety, and information required for efficient, ongoing operations.

The key in accelerating project execution for FLNG is in deploying recent technologies such as wireless and electronic marshalling combined with an advanced project execution model such as MAC.