For U.S. refiners, the bulk of project spending is on core business drivers including safety, environmental performance, and reliability programs. Projects that optimize performance and improve energy efficiency often don’t make the cut.

At the AIChE National Spring Meeting in Chicago, March 13-17, Emerson’s Pete Sharpe and Gary Hawkins, and Citgo’s Tom Novotny (Lemont refinery) will present a paper, “Quick Hit Financial Benefits from Pre-Engineered APC Packages”.

In this presentation, they’ll highlight this “quick hit” approach to create a self-funding program to improve the financial performance of the refinery demonstrated through a pilot optimization project.

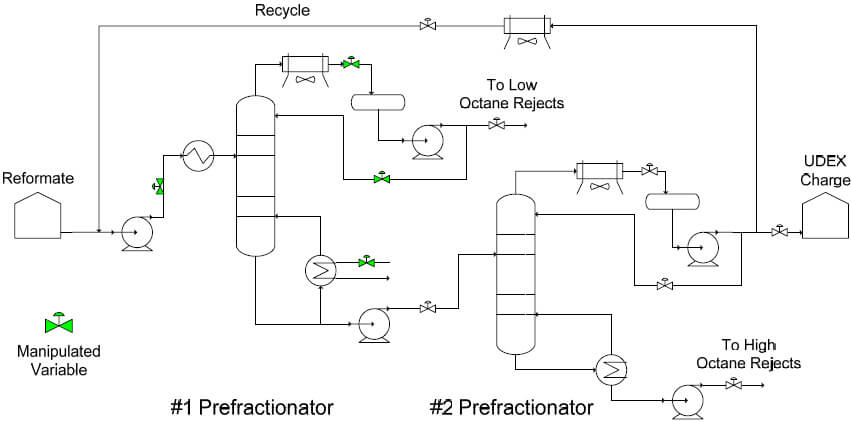

This pilot was proposed on a single process unit, either a distillation column, fractionator, or process heater. The total implementation cost was estimated to be less than $45,000 USD with a targeted payback in less than 6 months. The team chose a prefractionator distillation column on an aromatics extraction unit to apply a SmartProcess Distillation optimizer.

The project goals were to reduce benzene loss in the overhead by 30%, improve the column operating stability, and minimize energy consumed in the distillation process. From an economic standpoint, achieving these goals would mean $277,000 annually in increased benzene recovery from the gasoline pool.

The project team identified control variables and their operating targets for the tower top temperature, reboiler return tray temperature, tower top pressure, and feed tank level. The process constraints/limit variables included the reflux valve controller output, overhead receiver level, reboiler steam controller output, differential temperature across the overhead condenser, overhead flow rate, and towers 1 & 2 overhead pressure controller outputs.

Manipulated variables included charge, reflux, and reboiler flow rates, as well as top tower pressure. Other process variables affecting the system (disturbance variables) included reflux and charge temperature, as well as extractor charge flow rate on the downstream unit.

The team verified the integrity and performance of the unit’s control valves first and then performed step testing on the manipulated variables over the course of a day to understand the current process dynamics and compile the step test results into a comprehensive model predictive control model.

Not only was it important to thoroughly test, tune, and adjust limits when the model came online, it was important for the team to turn on a financial benefit tracking module, based on process data and physical properties. This would help to measure whether the project ROI objectives were achieved.

The project was completed in two weeks and had an immediate impact on the unit’s operations. With the help of the financial benefit-tracking module, tangible benefits led to a project payback in 40 days.

This “quick hit” approach showed it was possible not only to have the economic benefits fund the project in a short time period, it also showed how this refinery could execute these quick hit projects when openings to do them became available.

If you’ll be at the AIChE Spring National Meeting, and are seeking ways to optimize your plant in manageable chunks, be sure to catch Pete, Gary, and Tom’s presentation.

Update: I received some feedback from the project team, and made a change to sentence italicized above. While the economic benefits came quickly, the team has been working through some process issues with the surrounding units that has limited the average on-line time to 68%. But the statement about the 40-day payback was based on an average 68% uptime. Once the team fixes the valve downstream, they expect at least 95% uptime. If you assume 95% uptime, the payback would have been less than 30 days.