Emerson’s Dan Nower, a member of the machinery health management team, provides his thoughts on the importance of monitoring mechanical assets in mining operations:

As pointed out by Emerson’s Michael Pearson last week, the supply of copper is expected to be at a large deficit in 2011. It appears to be the same for other precious metals like gold and silver. To recover from these deficits, mining companies are required to maximize production and there is no better way to accomplish this than to optimize the use of their mobile mining equipment fleets. Open pit mining uses many types of moving equipment to harvest rare earth minerals and relocate the raw material to its processing location(s). This moving equipment includes shovels, draglines, loaders, mobile crushers, and much more. To optimize these fleets, each equipment type has to be monitored in its own unique way. Therefore, a monitoring system has to be adaptable to the equipment type it is monitoring.

Arguably, the mobile equipment type most difficult to successfully monitor is the Electric Rope Shovel. These shovels are very large, complex machines with large rolling element bearings and gearboxes. This machine complexity combined with the tough 24/7 service duty result in too much unplanned shovel downtime. Also, the typical changing speeds and loads during operating cause an extremely large variability in the information required to make accurate operational decisions to reduce this unplanned downtime. This unplanned downtime causes production losses and the inability to make up that precious metal deficit discussed earlier.

The more progressive mines have implemented portable vibration programs to reduce unplanned downtime. In order to safely gather repeatable vibration data to accurately diagnose issues on these complex machines, shovel outages have to be planned. These outages include mine operations planning on a monthly basis (typical) with the monitoring team, including equipment, and safety teams. These data acquisition outages require a minimum of three hours and as much as eight, depending on the skill of the analyst. Where this has shown an improvement in production, there is still lost revenue.

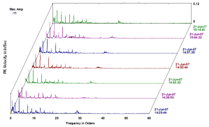

The next step is to automate this data acquisition. Automation would not only improve production, but also minimize the safety risks and eliminate planning errors. The predicates and I/O capabilities of Emerson’s CSI 6500 provides adaptive monitoring flexible enough to automate data collection techniques on the shovel’s most critical mechanical systems. Those systems include the swing, hoist and crowd. Vibration, system direction, rotational speeds and PeakVue (to be explained in a later blog) can be monitored and acquired during normal operation or during a ‘staged’ test. Because several variables need to ‘line-up’ during normal operation to acquire data, the chance of repeatable data being captured is small. It will still occur more than a couple of times per shift, far more that the once a month when using portable vibration data collectors. When those variables line up, the acquired data is repeatable. See figure on right for an example data set. Staged testing increases the chance of capturing repeatable data. This test can be run at the start of each shift, without an outage, or as the operator has an opportunity between trucks.

As you can imagine, there is much more that can be discussed regarding the monitoring of mobile mining equipment. As Jim Cahill discussed a few days ago, Emerson Exchange will provide a gathering of users of Emerson Process Management technologies and services, Emerson folks, Emerson local business partners and complementary suppliers in Nashville, Tennessee USA, later this month. At this event, you can soak up information provided by multiple presentations regarding Shovel Monitoring. Those include:

- Online Vibration Monitoring on Electric Mining Shovels – The Most Critical Equipment on the Mine Field—Jose Torres, MinePro

- Cyclic Vibration Data Collection and its Application in Mobile Mining Equipment—Rich Pratt, Cornerstone Controls / Emerson Process Management

Hopefully, I will see you there.