In the process optimization category of this blog, we’ve described many examples of advanced process controls and how they help to improve plant performance. One of the leading providers of multivariable APC over the years has been Aspentech and their DMCplus multivariable controller.

I caught up with Emerson’s Bruce Greenwald, whom you may recall from his Process Control Musings blog. Bruce shared with me that, while the DeltaV systems’ embedded APC suite provides a highly integrated set of tools and applications, many in the chemical and petrochemical industry already have DMCplus installed in addition to DeltaV control systems. Protecting their investment in DMCPlus is important, and while integrating with DeltaV is doable, connecting these together has required engineering effort.

Bruce noted that the Emerson team worked with Puffer-Sweiven, the Emerson local business partner in the Houston area, and engineers with a petrochemical manufacturer to develop a tool to simplify this integration process. The tool was designed to be generic and reusable for other sites where DMCplus and DeltaV were installed. The DMCplus application typically sits on a server outside the firewall at the edge of the DeltaV control network. It communicates through a single or redundant pair of OPC .NET gateways located inside the firewall to the DeltaV control network.

Bruce noted that the Emerson team worked with Puffer-Sweiven, the Emerson local business partner in the Houston area, and engineers with a petrochemical manufacturer to develop a tool to simplify this integration process. The tool was designed to be generic and reusable for other sites where DMCplus and DeltaV were installed. The DMCplus application typically sits on a server outside the firewall at the edge of the DeltaV control network. It communicates through a single or redundant pair of OPC .NET gateways located inside the firewall to the DeltaV control network.

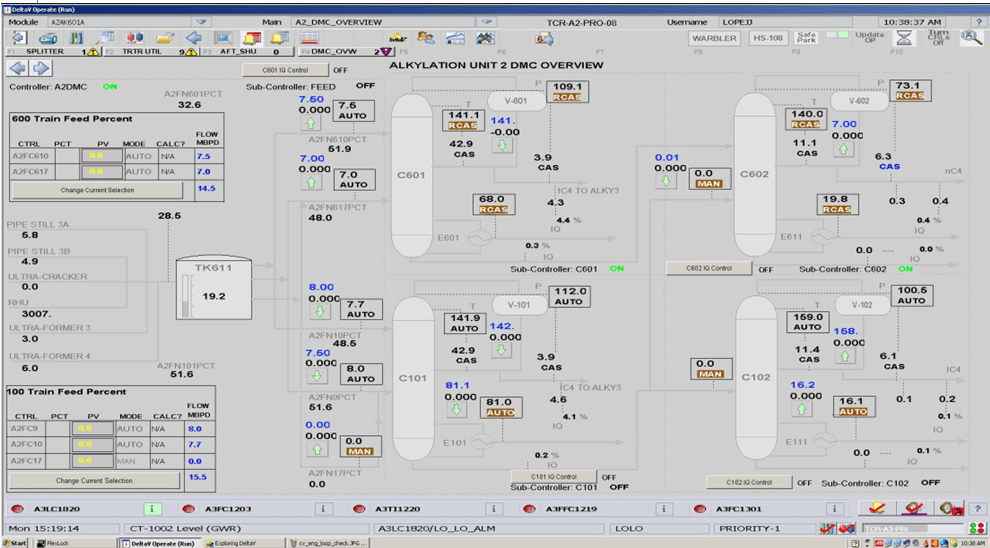

The tool was designed to be usable regardless of controller structure, size, or configuration. It also automatically creates the DeltaV configuration and displays to operate the integrated control. Bruce noted that it was designed to allow for the easy addition or deletion of manipulated variables (MVs), controlled variables (CVs), etc. Also, the graphics and DeltaV modules can be updated as required.

For those familiar with DMCplus and DeltaV, the tool works by parsing the DMCplus XML configuration, creating DeltaV configuration import files, and creating scripts to automatically create the operator graphic elements. Once created, the graphical elements and configuration modules can be easily changed if required.

For those familiar with DMCplus and DeltaV, the tool works by parsing the DMCplus XML configuration, creating DeltaV configuration import files, and creating scripts to automatically create the operator graphic elements. Once created, the graphical elements and configuration modules can be easily changed if required.

To support robust communications between the two applications, communications watchdogs, enhanced alarm and messaging, variable and mode validation, and integrated security within the graphics elements were created by the tool. From an operator standpoint, Bruce highlighted that the graphics simplified the diagnosis of controller shedding, operator entry validation for the variables in the multivariable controller, and provide links directly into Aspentech’s Production Control Web Server.

This integration tool grew out of a project but may become a more formalized application or product down the road. Until then, if you have DMCplus and a DeltaV system, feel free to connect with Bruce to discuss your application.