In today’s guest post, Emerson’s Mike McQuade shares how a mining pipeline valve application with huge torque demands necessitated a new valve actuator design to meet the challenge.

Three miles above sea level in the mountains of central Peru is the Toromocho open-pit, copper mine. When you visit the site, you are issued an oxygen tank to avoid altitude sickness. At this remote location, the largest Shafer actuator ever made will soon be installed. The application is what is referred to as a “tailings pipeline”.

Tailings are the materials left over after the process of separating the copper from the ore. To extract the minerals, the ore is pulverized and then infused with chemicals.

The tailings or waste material needs to be moved to a massive storage impoundment over three miles away. The Toromocho mining project will produce roughly 1.6 billion tons of tailings. The most economical method to transport this much material is to turn the powder into a paste and then pump it through a pipeline. Massive positive displacement pumps are required to move the paste creating pipeline pressures up to 2,030 psi. This high pressure combined with the dense slurry really drives up the torque requirements of the severe service valves.The largest valve in the pipeline is a 34″ ANSI 900, giant that requires torque well beyond the largest rotary vane actuator. In response to this and future needs, a new actuator was developed capable of producing 17.8 million inch-pounds of torque. This is the second time in the last three years that a larger actuator needed to be designed for mining applications.

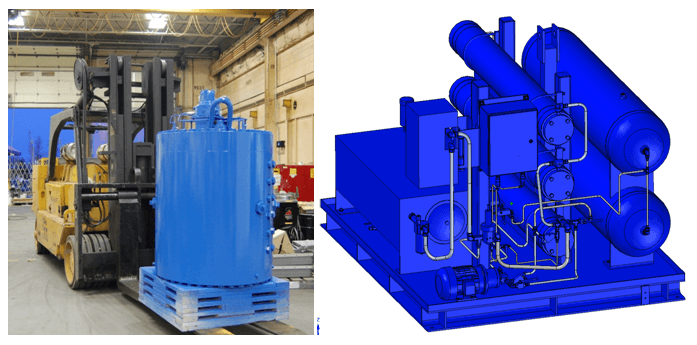

The total project scope included 55 rotary vane actuators and 2 hydraulic power units, one of which was specially designed to be mobile and mounted in the bed of a truck. J.C. Cervantes had the project lead with the valves being supplied by ValvTechnologies, Houston and the EPC work done through Aker Solutions in Tucson.