Hello again—Chris Womack here with another guest post.

Hello again—Chris Womack here with another guest post.

The specialty-chemical industry’s big European convention, Chemspec Europe 2013, features an Emerson exhibit for the first time this year. The meeting is going on right this minute in scenic Munich, Germany. So if you’re attending, be sure to stop by our booth 3H15—or “stand” 3H15, in the region’s parlance—to say “wie gehts” and take a look at what Emerson has to offer.

Also, don’t miss the June 6 presentation about Coriolis mass-flow meter innovations (abstract pdf) that Emerson Business Development Manager Sonal Gilani is delivering on the exhibit floor as part of this year’s Royal Society of Chemistry Symposium.

Also, don’t miss the June 6 presentation about Coriolis mass-flow meter innovations (abstract pdf) that Emerson Business Development Manager Sonal Gilani is delivering on the exhibit floor as part of this year’s Royal Society of Chemistry Symposium.

As it happens, I got a sneak peek at Sonal’s presentation, so read on for a few highlights.

After her introduction, Sonal will talk about a few of the general benefits that specialty chemical manufacturers can gain from Coriolis flow meters—particularly Micro Motion Coriolis meters. For example, Coriolis meters provide a direct mass measurement—even in liquids containing entrained gas—which is especially useful in a field that depends on accurate stoichiometric ratios. Also, Coriolis meters don’t have any moving parts, so they require very little service. Micro Motion meters in particular can provide users with a device-health report in a minute and a half.

In practice, when a major drug maker replaced its aged differential pressure meters with 200 of Emerson’s two-wire Micro Motion Coriolis meters at its U.S. animal products plant, the company immediately discovered that its feed flow rates were about 100 liters/minute higher than expected. The firm hopes its switch to Coriolis will improve process efficiency by at least 5 percent, and that it’ll improve uptime, which sat at about 80 percent, thanks to maintenance needs, upsets, and planned shutdowns.

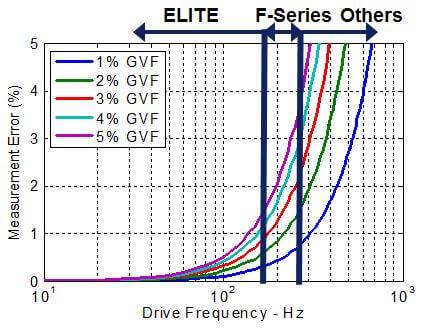

About those innovations—one example is the capacity of Micro Motion ELITE Peak Performance meters to accurately gauge mass flow in the presence of entrained gas. (Below, GVF is gas volume fraction.)

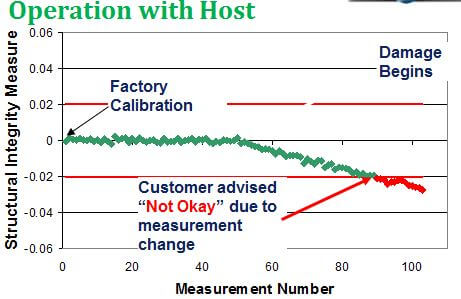

Another innovation is in-line verification. While Coriolis meters themselves need very little service, it’s sometimes necessary to check whether erosion, cracking, or pitting has altered tube stiffness—and altered flow meter measurements, as a result. Typically this verification is carried out by removing the Coriolis meter from the process—physically taking it off-line for inspection. Smart Meter Verification allows plant personnel to verify tube stiffness of a Micro Motion meter using a series of test tones without removing the meter, and without interrupting the process.

The graph below depicts a series of such verifications. Around measurement number 90, Smart Meter Verification signals the user that tube structural integrity has moved beyond the allowable range, and that it’s about to threaten measurement accuracy.

Structural Integrity Measurements versus Measurement Number during Smart Meter Verification

For more, catch Sonal on Thursday, June 6, at Chemspec. She has a lot more to share about Coriolis innovations and success stories.