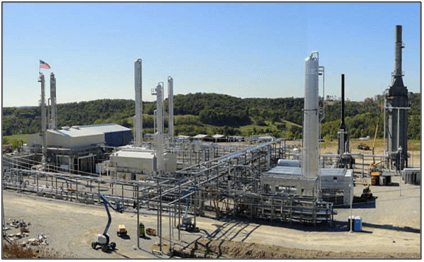

The 92nd Annual Gas Processors Association (GPA) Convention was held last week, down the road from me in San Antonio, Texas. Two of the Emerson business platforms, Emerson Process Management and Emerson Climate Technologies were there to show ways technologies are being applied to help address the technical challenges related to the shale gas infrastructure expansion occurring in North America and other parts of the world.

Here are some of the discussions that took place from the Emerson team in attendance. One application discussed was an integrated approach for gas plant refrigeration optimization. These refrigeration systems are critical for the liquids (Natural Gas Liquids-NGL) recovery portion of these gas-processing facilities. These heavier hydrocarbons (typically propane) are recovered using mechanical refrigeration.

Here are some of the discussions that took place from the Emerson team in attendance. One application discussed was an integrated approach for gas plant refrigeration optimization. These refrigeration systems are critical for the liquids (Natural Gas Liquids-NGL) recovery portion of these gas-processing facilities. These heavier hydrocarbons (typically propane) are recovered using mechanical refrigeration.

For this application screw compressor technology provides high-pressure handling with low bearing loads, discharge pressures above 900 PSIG and flow rates up to 4.3MMCFD. The compressor and systems are driven by motors from 200 to 2,000HP. Capacity and volume ratio can be controlled independently with volume ranging from 1.2 to 7 and capacity from 10-100%.

Depending on the application, the Emerson Climate technology is combined with instrumentation and controls from Emerson Process Management, including Fisher valves and regulators, Rosemount pressure and temperature transmitters, CSI vibration sensing and online monitoring, and integration with control systems, such as the DeltaV system. The goal is to match the process conditions with the refrigeration compressor design to minimize energy costs and operate at the best efficiency levels. The Emerson works with gas processors to package these technologies together into integrated skids to meet the process requirements to achieve these efficiency and performance objectives.

A second application that was discussed was tank vapor recovery. Scroll compressors are well suited for this application, since they are rated for hazardous area and have no shaft seals, valves, or wear parts. They can be used in pipeline gas applications up to 400MCFD at discharge pressures of 325PSIG, with a compression ratio up to 13 from suction to discharge. They can also be operated with variable speed motor control to adjust to changing compression requirements.

A second application that was discussed was tank vapor recovery. Scroll compressors are well suited for this application, since they are rated for hazardous area and have no shaft seals, valves, or wear parts. They can be used in pipeline gas applications up to 400MCFD at discharge pressures of 325PSIG, with a compression ratio up to 13 from suction to discharge. They can also be operated with variable speed motor control to adjust to changing compression requirements.

The vapor recovery system skid can include remote terminal unit (RTU) controllers and HMIs, Rosemount pressure, temperature and level measurement, and Fisher level controllers, as well as Control Techniques variable speed drives, ASCO solenoid valves, and SOLA power supplies from the Emerson Industrial Automation business platform.

The wealth of shale gas poses a challenge to increase the capacity to process this natural gas. Technologies and expertise to package, install, and optimize these technologies spans many of the Emerson business platforms.