Imagine 30% of a country’s energy supply relying on two safety shutdown valves to flow natural gas and liquid condensate safely from offshore oil & gas production platforms to an onshore processing facility. It’s critical that the valve actuators reliably perform their function to close the valves when a shutdown command is issued by the safety instrumented system.

Emerson’s successful cooperation between UK Sales Andy Pusey and Coos van Minnen, a member of the European sales development support team and an Oil & Gas and Pipelines Industry Specialist in the Valve Automation business unit, shared a story with me about the actuators designed to meet the requirements of this demanding application. They pointed me to an article, Giant Emerson valves going overseas. According to the article’s author:

Two valve actuators Emerson has been assembling for Shell UK, in Great Britain, are far too tall and heavy to be worked on indoors. Standing 18 feet [5.5m] high with a weight of six tons [5440kg], the actuators, which look like little more than long, thin tubes of steel but are actually high-precision instruments, are scheduled to be shipped overseas today.

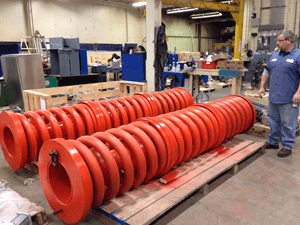

Spring being mounted into the safety shutdown valve’s actuator at Emerson’s Valve Automation manufacturing facility.

The actuators were designed, engineered, built, and assembled in the Emerson Process Management Valve Automation facility in Mansfield, Ohio. The design is based on the Bettis GVO Series of Linear Valve Operators scaled up to generate the required force to hold the safety shutdown valves open under startup and operating conditions. The actuators are a fail-close design held open by hydraulic-spring return design operating at 1900-3000 psig [131-207 bar] operating pressure. The actuator design complies with the European Commission’s Pressure Equipment Directive (PED) 97/23/EC and ATEX.

With the valve actuators now in route across the Atlantic Ocean to the European Valve Automation World Configuration Center in Hengelo, The Netherlands for the Cycle test, NAS 6 cleaning –Coating and installation of the Fireproof protection system to protect actuator and controls. This is done in accordance to the UL 1709 prior to being transported to the gas plant. This project will proceed in two phases to swap out each of the existing actuators with these new ones.

To connect and interact with Coos and other valve actuation professionals, join the Actuators track of the Emerson Exchange 365 community.