As described by MarketRealist, raw natural gas from wells contains numerous components. While mostly methane, a dry gas, and wet gases including ethane, propane, normal butane, isobutane, and natural gasoline, along with water, carbon dioxide, and sulfur. The article’s author notes:

I exchanged emails with Emerson’s Ji-yoon Han who shared some background, challenges, and the thoughts of Anand Shukla on ways to manage custody transfer of these NGLs.Natural gas processing removes impurities and separates natural gas liquids (or NGLs) from dry gas. Processing is valuable because natural gas liquids, as separate components, have their own applications and are worth more extracted from the raw gas stream.

Anand is presenting at the GasTech conference this week in South Korea. Here is his presentation’s abstract:

With shale boom in USA, evacuation of NGL from far-flung shale fields has seen the advent of trucking and rail fleets that carry NGL to its users. The presentation discusses how automation solution can address key NGL truck loading challenges related to safety, reliability, accuracy, footprint, weight, OPEX and CAPEX. The NGL/LPG truck loading metering skids are designed to minimize environmental impact. Emerson solution consists of fully integrated skid with piping system, valves, metering, transmitters and batch controller. Whole design is fully integrated, tested and optimized for best accuracy, performance and least footprint.

I’ll highlight some of the key points from Anand’s presentation. The price of these wet (high BTU) NGLs is a primary driver of shale gas development in the U.S. and other countries around the world. The challenge is the infrastructure required to move these NGLs from the producing wells to the gas processing facilities, which perform the separation and purifying operations.

Lack of pipelines drive the need for other forms of transportation including rail, truck, and ship. Rail is highly flexible, allowing oil & gas processors to adjust orders between terminals and receive deliveries via different railroads. The transportation option with maximum flexibility, trucking costs less than rail, but are limited to 250 miles by safety restrictions. Ships offer bulk delivery in and out of limited marine terminal locations. Trucking/rail is used to distribute product to demand centers.

The process requirements are similar between truck loading, gas processing, and fractionation plants. According to the current version of Wikipedia’s Natural-gas processing entry:

Most cryogenic plants do not include fractionation for economic reasons, and the NGL stream is instead transported as a mixed product to standalone fractionation complexes located near refineries or chemical plants that use the components for feedstock.

Natural gas processing combines the natural gas liquids with the equipment and process automation to safety and efficiently operate the plant. Fractionation plants include the NGLs plus storage capabilities. The NGLs are transported via pipeline, rail, and truck.

For the NGL custody transfer, Anand highlighted several requirements. The custody transfer system needs the flexibility to load odorized and non-odorized propane, normal-butane, iso-butane, and natural gasoline via truck / railcar. The measurement equipment typically must be skid mounted and the measurements connected back to the corporate business system. The custody transfer must be in accordance with the API custody transfer standards with pressure and temperature compensation.

The loading system needs to provide driver identification and authorization to start loading and provide a interface for the driver to interact with the system. Anand shared a turnkey NGL loading solution with me that includes upfront design, project management & engineering, sub-contractor management, installation/commissioning/training/maintenance services, and ongoing operations support.

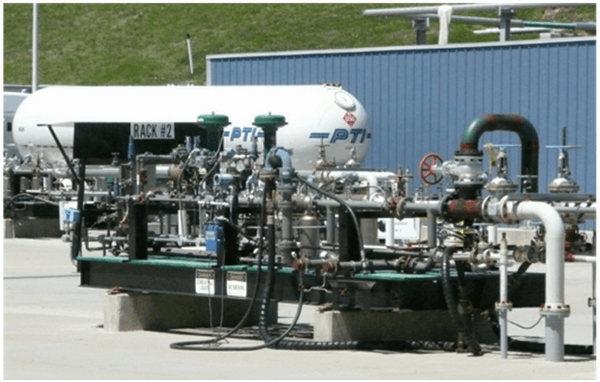

The solution consists of fully integrated skid with piping system, valves, metering, transmitters and batch controller. The design is fully integrated, tested and optimized for best accuracy, performance and minimized footprint.

Some of the Emerson technologies in this NGL custody transfer skid include: DL8000 preset controllers, Fisher control valves and regulators, Micro Motion Coriolis mass flow and density meters, Rosemount pressure & temperature transmitters, Syncade logistics software, a DeltaV control system, position limit switches, and Bettis valve actuators. Technologies from other suppliers include miscellaneous manual valves/gauges, pressure relief valves, safety couplings, earth ground detector, and media converters.

The combination of these technologies with the lifecycle services provides for quicker projects, single accountability, optimized operations, and measurement sustainability through the lifecycle of the custody transfer system.

You can connect and interact with Anand and other oil & gas professionals in the Oil & Gas track of the Emerson Exchange 365 community.