Hi, I’m Lee Rumbles and today we’re going to explore the importance of flow measurement in the oil and gas separation process.

Hi, I’m Lee Rumbles and today we’re going to explore the importance of flow measurement in the oil and gas separation process.

Understanding what’s truly going on in your process is a key to success. Without this insight it’s difficult to tell – are we maximizing production? Is the output of optimum quality? Am I getting the most out of this effort?

With efficient oil and gas production operations, the separator is how these questions (and more) are answered.

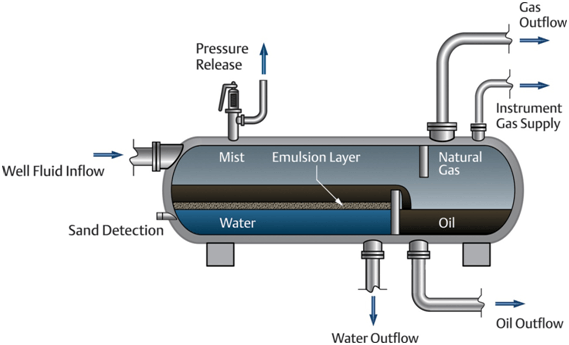

Separators reside on onshore well pads and offshore platforms and can be horizontal, vertical, or a sphere. They’re used in upstream oil and gas applications for periodic well testing (as a test separator) or continuous production measurement (as a production separator), and can function in either two-phase or three-phase depending on operator strategy.

The separator has one goal: separate the oil from the gas and water. But, if you choose the best flow measurement for your separator, you can really make it work to not only meet this goal, but also deliver much more insight into your operation.

What’s the big deal about flow measurement?

With quality flow measurement on your separator, you can:

- Tell how your well is performing and how much oil, water, and gas you’re producing

- Fine-tune your recovery operation to maximize retrieval of hydrocarbons

- Manage the decline curve of your wells

Assuming a three-phase separator, as shown below, let’s explore how you can make the right decision on the kind of flow measurement you might need for each point.

Pressure Release. Let’s start with safety. You’ve got a closed vessel operating in a dynamic situation with fluid entering and exiting, valves opening and closing, pipes could be leaking or slowly closing with buildup, and you are relying on instrumentation controlling what you can’t see. There’s a reason ASME and API establish codes to ensure the correct management of separator pressure.

Relief valve & position monitor: Look for quality instrumentation specifically designed to protect from over-pressurized situations and alert you when gas volumes are vented. For an even smarter choice, consider a wireless monitor that advises (remotely) when the valve is open or closed.

Rupture disc: Can be used as a relief system but, if it is required, its purpose is to break in order to relieve an over-pressurized situation. The result is that the valve will stay open, venting, until someone replaces the disc.

Gas Outflow. In order for a separator to function, it requires a steady, maintained level of pressure in order to push the fluids out of the separator and into a tank. If the pressure’s too high, you can get gas entrained in the oil where it will simply vent off from the tank resulting in higher emissions and lost product. If the pressure’s too low, you can lose the more valuable, lighter, or intermediate gases (called natural gas liquids or NGLs) as they get pulled out into the natural gas. NGLs have a higher BTU content and you’ll want to keep these valuable BTUs in liquid form.

- Regulator: Look for regulator devices that have a much higher pressure tolerance and can minimize pressure deviations within the separator. Likewise, technologies that deliver a faster reaction time to pressure changes offer a better solution to safety and maximize production.

In some applications, the Gas Outflow serves as a custody transfer point. If so, you’ll want to know how much gas each well is producing and there are several flow measurement technologies that can help.

- Orifice meter: Quality orifice devices, that are field-proven, can deliver what’s needed. Look for devices where you can change the orifice plate as the field ages and production declines – this gives you added flexibility and extends the utility of the device while providing a means for easy inspection.

- Coriolis or Ultrasonic meter: Excellent accuracy for any custody transfer point is provided and can also deliver diagnostic information whether the separator is operating at peak efficiency.

- Vortex meter: An accurate meter for allocation measurement when you need higher rangeability without having to change plates or adjust for production conditions. Vortex meters are not currently recognized by AGA or API for custody transfer of gas.

Instrument Gas Supply. When using the natural gas from the well to operate valves within the separator, you need to properly regulate pressure to the pneumatic controllers of the valves. If you don’t have sufficient pressure within the separator or the instrument supply regulator fails, your devices aren’t working properly and you can quickly lose control of the separator operation.

- Regulator: Count on devices that are proven in the field so you can confidently maintain reliable and consistent instrument gas supply pressure.

Oil Outflow. Like a quality check of the entire separator, the oil outflow flow point provides insight into how the well is performing and delivers an indication of reservoir decline rates. The oil outflow is critical as it’s used as an allocation measurement to calculate any royalties owed to the landowner.

- Coriolis meter: Highly accurate, no parts that wear, and diagnostic insight ensure you don’t over – or under – pay on critical royalty payments.

- Ultrasonic meter: Similar benefits to Coriolis, but different underlying flow measurement technology, the ultrasonic meter is typically used on large separator applications (3″ and above).

- Water cut meter: A newer technology for use with a 2-phase separator, with a net oil computer and/or a Coriolis or density meter, you are able to detect the actual amount of water and oil from the outflow. These devices are being used in larger, conventional fields and offshore.

Water Outflow.

Produced water is a by-product of oil production and can provide indication of where the reservoir is on the production decline curve. It can also serve as a simple indicator as to how often water tanks need to be emptied. In some oil fields, how much water is produced must be reported for regulatory reasons.

- Coriolis meter: The big advantage of a Coriolis meter in this kind of application is as another quality checkpoint to determine if there is any oil in the water.

- Ultrasonic meter: Similar benefits to Coriolis, but different underlying flow measurement technology, the Ultrasonic meter is typically used on large separator applications (3″ and above).

- Magnetic meter: A straight-forward device that has no moving parts and no path obstructions, the magnetic meter does require a certain amount of power. This may restrict its application in solar-powered, remote fields.

- Vortex meter: With the advantage of no moving parts, the vortex meter also meets the requirement for low-power installations. Care must be taken to size the vortex meter correctly, however, to ensure dump cycles are sufficient in duration and above the low flow cutoff of the meter.

Sand Detection. This is a unique flow point on a separator, however can be critical to keeping your operation going. If the reservoir or type of production application produces sand, it will start to settle in the bottom of the separator. Simply put, the sand takes up space and limits the capacity (retention time) of the separator, requiring periodic clean out.

- Direct Insertion Density meter: A simple solution to advise you of the sand level within the separator so you can proactively schedule cleanout before lost retention time causes oil/water contamination.

Now you can see the importance of good separator practices in the field and how flow measurement selection can really provide value to your operation. In the next post, we’ll explore how, using the best flow measurement technologies, you can truly optimize your separator and make it work to your advantage in maximizing production.