Process manufacturers and producers are faced with a myriad of regulations at the federal, state and local levels. Here in the U.S., refiners are challenged with the Environmental Protection Agency (EPA)’s “Tier 3” regulations, which rule that:

In the first of a series of Refining Blending webinars, Emerson’s Dr. Doug White presented, Creating a predictable path to Tier 3 compliance. This webinar was recorded and is now available for viewing. I’ll recap a few points that he shared in the webinar.…federal gasoline will be required to meet an annual average standard of 10 parts per million (ppm) of sulfur by January 1, 2017.

Doug is a senior principal consultant with more than 30 years of experience in the technology, economics, operation, and control of major refinery and chemical processes. He has designed, implemented, and economically justified state-of-the-art advanced manufacturing automation, advanced control, supply management, decision support, and information systems in process plants around the world.

Doug opened sharing the objectives for the webinar series in first highlighting the Tier 3 regulations and their impact on refiners and then exploring ways to meet the requirements in the most cost-effective manner and looking at the most profitable opportunities to improve blending operations. In describing the regulations, he noted that large refiners would be impacted first in 2017 with smaller refiners given a 3-year grace period until 2020 to meet the standards. These new levels are based on the state of California’s Low Emission Vehicle (LEV-III) program.While the average sulfur ppm moves from 30ppm in Tier 2 to 10ppm in Tier 3 for all of a company’s refineries, any one refinery cannot exceed 80ppm when it leaves the refinery or 95ppm at the gas pump. As Doug pointed out, these higher levels allowed are only theoretical since simple math would demonstrate that it would take really low levels to get the average down to 10ppm. There are also provisions for credits and trading to meet these levels.

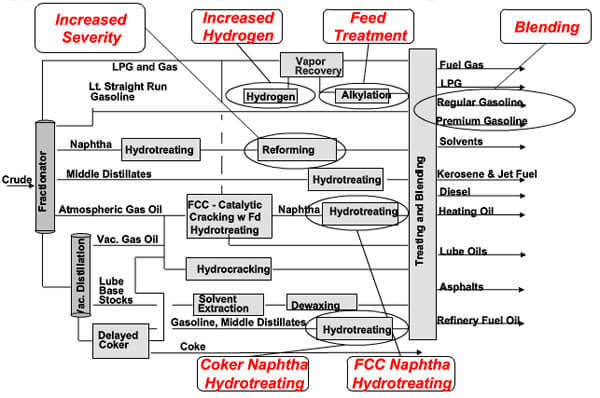

Refineries are impacted with need for additional naphtha hydrotreating and coker naphtha hydrotreating where coke goes into the gasoline formulation. Hydrotreating requires more hydrogen which increases demand on the hydrogen unit. The alkylation unit is another area which may require feed treatment to meet the 10ppm sulfur limit. Octane losses may also require increasing the severity of catalytic reforming operations.

The impact on blending operations typically will mean updated blenders and tankage upgrades. For older refineries, measurement devices, control valves and other instrumentation will need updating to operate the blending operations with minimal variability to keep within the sulfur limits. The final value of the refined products is significantly impacted by the quality of the blending operations.

As part of the project scope to meet the regulations, an opportunity exists to increase process availability and safety through the addition of tank overfill protection, pump and valve health monitoring and better flow measurement accuracy by measuring mass flow. Watch the webinar to see some of the value refiners have captured working with the refining industry consulting team.

A couple of questions were raised during the webinar which you can see along with the answers in an Emerson Exchange 365 refining post, Is it viable to reduce working capital by blending into a pipeline? After watching this webinar, if you have additional questions, add you question to this thread for the refining team to address.

The next webinar in the series will be Using automation to meet your production plan and Tier 3 regulations on June 11 at 1pm CDT. We hope you can join Doug and the team then!

Update: Links to webinars fixed.