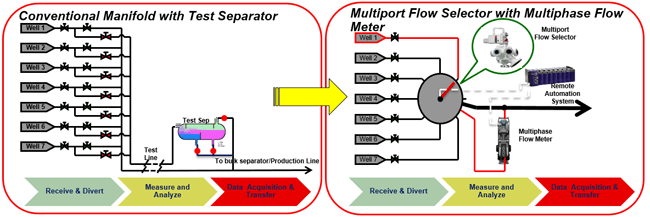

Testing the composition oil, gas and produced water and basic sediment from oil & gas wells has traditionally required test separators. For offshore platforms and onshore well pads with multiple wells, this has meant complex manifolds and valves to route the production coming from an individual well between the test and production separators.

Emerson’s Joseph Zawacki shared some background with me on an integrated well testing approach. He first noted that for offshore production platforms weight of the processing equipment is an issue and cost between $5,000 and $35,000 per ton to install.This means that anything that reduces this weight, footprint and complexity also reduces risks and costs associated with the project.

In an integrated well test solution, the conventional manifold is replaced with a multiport flow selector (MPFS). The test separator is replaced with a multiphase flow meter (MPFM). And the traditional data acquisition system is replaced with a remote automation system/remote terminal unit to provide automated well testing operations.

In addition to less weight and footprint, the integrated well test approach provides improved reliability and reduced travel exposure and better insight into current well production composition to support optimization. This improved information can help increase the viability of marginal fields and platforms.

If you like to see the components in the integrated well test and speak with oil & gas composition flow experts, visit the Emerson team at the Offshore Technology Conference—OTC 2016. Register to receive a complementary OTC day pass for more on this and other oil and gas solutions.

You can also connect and interact with other oil & gas experts in the Oil and Gas group in the Emerson Exchange 365 community.