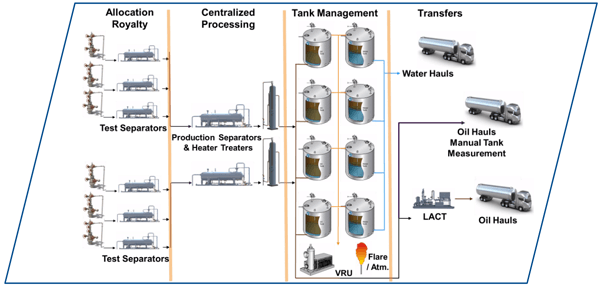

Managing produced oil & gas fluids go through the phases of allocation royalty, centralized processing, tank management and transfers. The opportunities for inaccuracies and losses can be quite high.

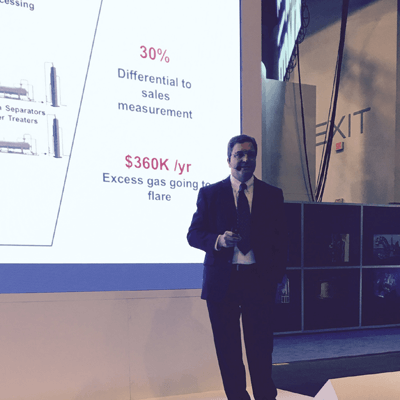

At the 2016 Offshore Technology Conference, Emerson’s Jody Overshiner explained that in the allocation royalty and centralized processing phases where the fluids are separated into components, the goal is to minimize allocation errors, ensure the integrity of royalty payments, reduce maintenance costs and minimize gas to tanks and flare. Flaring excess gas for some fields can cost up to $360K per year from what otherwise could be sold.

At the 2016 Offshore Technology Conference, Emerson’s Jody Overshiner explained that in the allocation royalty and centralized processing phases where the fluids are separated into components, the goal is to minimize allocation errors, ensure the integrity of royalty payments, reduce maintenance costs and minimize gas to tanks and flare. Flaring excess gas for some fields can cost up to $360K per year from what otherwise could be sold.

In the tank management phase, the goals are to minimize accounting errors and manage inventory, reduce production losses, ensure HSE performance, control and recover vapors and prevent spills. Opportunities for greater efficiency include automatic tank gauging to reduce unaccounted for losses. Vapor recovery units can reduce flare gas and send it over for processing and sale.

For the transfers phase, the goals are to improve fiscal transfer operations & logistics, reduce losses & theft, ensure fiscal transfer accuracy and verify salt-water disposal well (SWD) disposal costs. Losses come from oil transfer measurement inaccuracies and SWD overcharges.

One oil & gas producers had more than 3000 manual tickets per month for truck lease automatic custody transfer (LACT) operations transferring more than 550,000 barrels per month. Operators and administrators managed the entry and correction of tickets with data lags up to two days and inaccuracies could be up to 3-5 barrels on each load.

Through the automation of this process, losses over $19 million annually could be significantly reduced.

Opportunities to improve the process include automated haul tickets, continuous tank level measurement, remote operations with cross-functional collaborative workflows and high accuracy and reliable fiscal flow measurements. These solutions can be installed in scalable steps to bring improvements across the production to sale lifecycle.

For more, visit the Produced Fluids Management section of the Emerson website. You can also connect and interact with other oil & gas experts in the Oil & Gas group in the Emerson Exchange 365 community.