Increasingly, plants are having to adapt to more flexible operations as gas prices remain low and renewables are added to the generation mix. Gas units are shut down, started up in the morning, follow load during the day, and then are shut down or idled again.

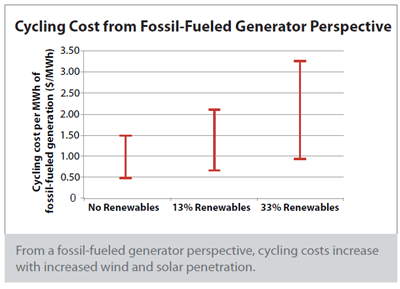

Source: National Renewable Energy Laboratory: The Western Wind and Solar Integration Study Phase 2

- Many of these units were not designed to operate this way

- Ramp rate and loading requirements are more complex

- Plants required to startup, shutdown, and transition more often are sometimes using older processes and procedures that inhibit their ability to be more agile and may be using more fuel than necessary.

The good news is that these plants are capable of becoming more flexible with some changes. Some utilities will choose to undergo complete boiler and turbine retrofits to make a unit more suitable for cycling, but in most cases, changes to control strategies combined with some targeted equipment modifications can improve operations greatly.

During the upcoming POWER-GEN conference in Orlando (December 13-15), experts will be on hand for Emerson to discuss how to achieve more flexible plant operations. Technology will be exhibited that provides the automation necessary to improve operational flexibility. Stop by the Emerson booth to discuss a host of topics. Here is a sampling:

- Optimized heat delivery enhances part load combined cycle efficiency by improving gas turbine exhaust temperature

- Achieve hot start and hot transition fuel savings

- Optimize steam temperature and ramp rate with model predictive controls

- Achieve more efficient low load operations

From Jim: Be sure to get your free day pass now to connect and interact with the Emerson team at POWER-GEN. You can also engage with other power generation experts in the Power group in the Emerson Exchange 365 community.