Continuous processes still must go through startups, planned and unplanned shutdowns, upset recovery and other events. These operations have traditionally been performed manually.

At the October 14-16, 2019 AFPM Operations & Process Technology Summit in San Antonio, Texas, Emerson’s Courtney E. (Eddie) Lane will present with a Global Process Automation Technology Leader for a major chemical manufacturer. The subject of their presentation is State-Based Control of a Vinyl Acetate Monomer Production Process.

I’ll preview some key ideas in their presentation. Eddie and the technology leader will open their presentation defining procedure automation. Operational procedures are administrative-based control with formal sequences of instructions that are executed by process operators. This mode of operation is typically task oriented and can reduce the likelihood of human error.

Procedure automation automates aspects of operational procedures and typically have a unit operation-level scope. These procedures coordinate multiple unit operations, based upon ISA106, Procedure Automation for Continuous Process Operations.

The value procedure automation can deliver includes enhancing operations assessments, improving situational awareness, unifying operational understanding, retaining knowledge, enforcing best practices, reducing human error, and gaining overall performance. These improvements come from executing more steps in parallel, capturing and automating best practices and capturing efficiencies into the procedures.

The value procedure automation can deliver includes enhancing operations assessments, improving situational awareness, unifying operational understanding, retaining knowledge, enforcing best practices, reducing human error, and gaining overall performance. These improvements come from executing more steps in parallel, capturing and automating best practices and capturing efficiencies into the procedures.

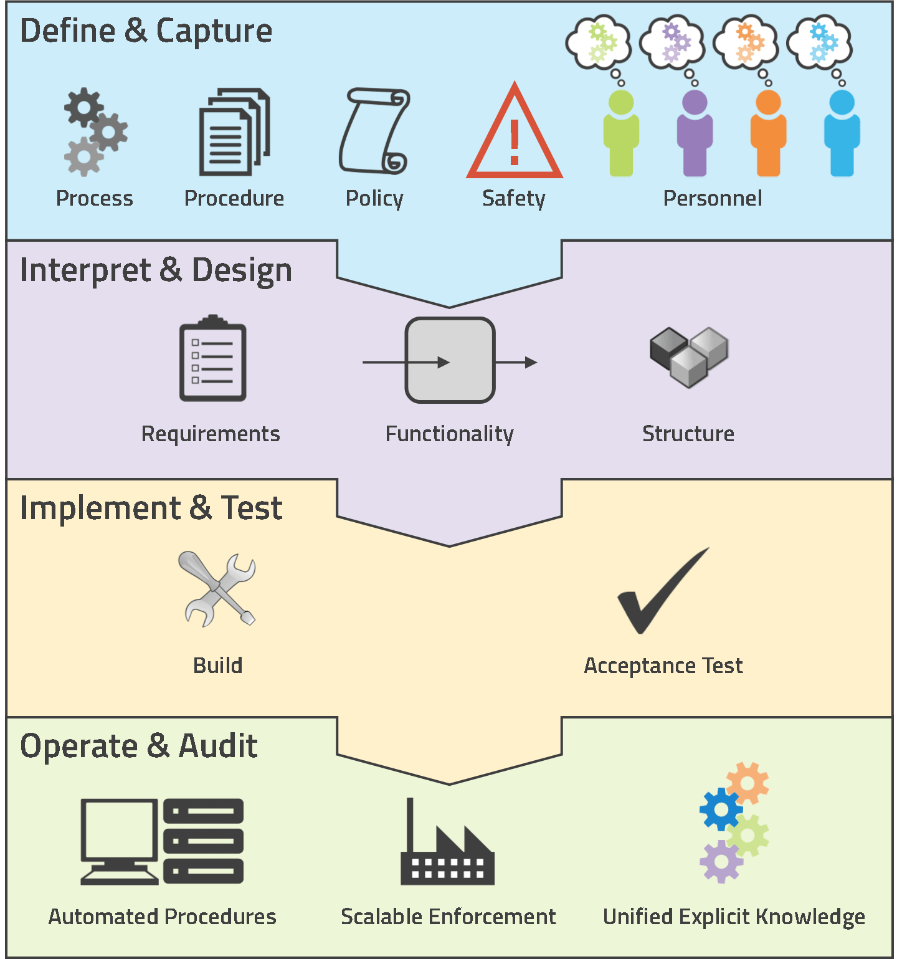

Moving from manual to procedure automation requires first defining and capturing current processes, procedures, policies, safety practices, and tacit operations and maintenance knowledge. Next, this information is interpreted and developed into requirements, functions and structures. From these design efforts, procedure automation is built and tested. Finally, these are put into operation, refined and improved over time.

Procedure automation can be implemented as state-based control which consists of unique states and transitions to move between states. The states remember information about the system and all of the states together comprise the overall state space. How the system inputs and outputs move through the state space dictates the behavior (outputs), inputs and current state dictate next state (transitions).

They share an example of a piece of process equipment such as a distillation column. It has states offline, shutdown, startup and running. These states are defined from the process knowledge of how they should operate. The outputs from each state are defined by the operational procedures.

If you’ll be at the AFPM Operations & Process Technology Summit, make sure to catch their presentation at 10:15am-11:00am on Monday, October 14. Their presentation covers much more including opportunity identification for procedure automation, requirements formalization, the specifics of this applied to their chemical production process, and the results achieved.

You can also connect and interact with other refining, petrochemicals and chemical industry experts in the Chemical and Refining groups in the Emerson Exchange 365 community.