Author: Michael Thambynayagam, Emerson Distinguished Contributor

The oilfield is made up of three constituents: the reservoir, overburden, and surface facilities. Data are acquired from these constituents and archived continuously. The information is continuously used to construct the model of the oilfield that evolves in real time. A prerequisite to oilfield automation is the ability to seamlessly connect real-time streaming data from sensors to simulation and analytics. Central to such a mission is a high-speed oilfield simulator. The simulator must be capable of mathematically modeling the oilfield as one entity. Combined with built-in AI, it enables automation of both optimization and history matching. The model of the oilfield evolves in real time, garnering predictive capability with each update from the history-matched data.

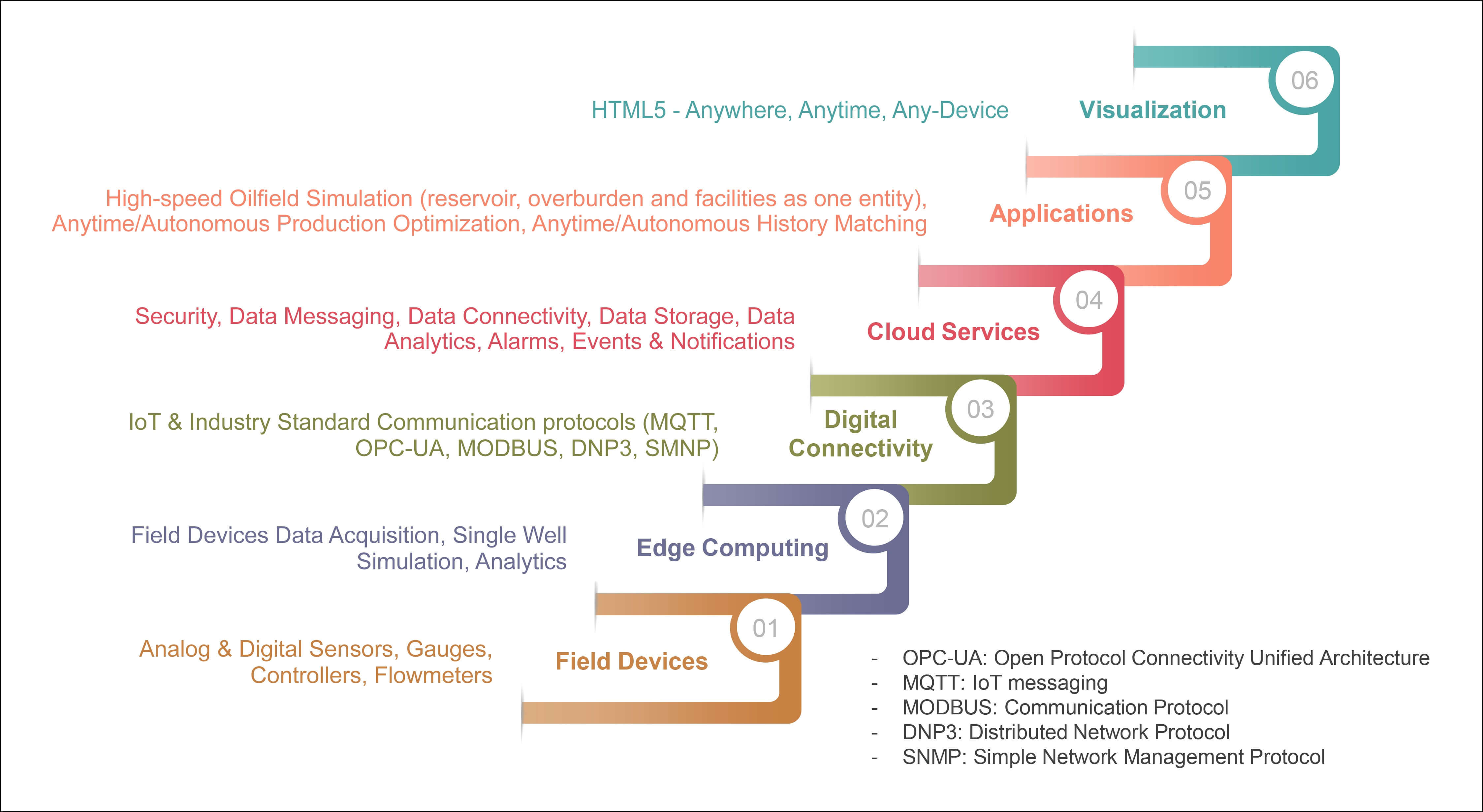

A high-speed simulator, coupled with a resourceful and efficient, Industrial Internet of Things (IIoT) system capable of reading directly from sensory devices, can process and analyze large volumes of data at rest and in motion, resulting in a system capable of true oilfield automation. The IIoT in this context consists of six horizontal layers of core services: field services, data acquisition and analytics, IIoT and industry standard communication protocols, security and messaging, applications, and visualization anywhere, anytime. These services are vertically combined to achieve solutions that transcend the entire oilfield. The resulting self-learning system can diagnose problems, anticipate events, and, where possible, provide remedies. Such a system will immensely enhance the operational efficiency of an oilfield that includes hundreds of wells, while optimizing asset performance across the oilfield’s full life cycle with minimal human intervention.

Scientists at Emerson Automation Solutions have developed a high-speed oilfield simulator for recovery of unconventional resources. The forward predictions from such a high-speed simulator used in tandem with AI-assisted autonomous history matching yields superior performance.

Integration between geophysical and reservoir engineering data, constructing static and dynamic oilfield models, and quantification of uncertainty, especially that resulting from seismic time-to-depth conversion, will remain at the core of our processes. “Industry 4.0” solutions are not a substitute for such tried and tested methods. Rather, they exploit them in a digital environment, which reduces time and eliminates risk attributable to human error. The application of AI will continue to play a central role in the digital transformation of our industry, but it must be helped to evolve to complete autonomy under the watchful eye of humans, to ensure that the laws of physics are obeyed.

This blog is an excerpt from an article, Digital Transformation: Quest for Operational Efficiency, appearing in the Journal of Petroleum Technology, July 1, 2019.

From Jim: Learn more about Emerson’s high-speed simulator and other latest innovations at the Sep 30-Oct 2, 2019 SPE Annual Technical Conference and Exhibition (ATCE) in Calgary.