As electrical power producers and cogeneration facilities must handle the load swings produced on the supply and demand side. Optimizing steam temperature control is one key way to improve the reliability of on boilers and heat recovery steam generators (HRSGs) caused by load swings.

I caught up with Emerson’s Jeffery Williams who shared the details of a steam temperature optimization project with me. For one U.S. chemical manufacturer, its 18MW coal-fired, cogeneration power plant produced steam for the site’s chemical manufacturing processes. Due to changing load demands for these processes, they were challenged with steam temperature stability, turbine life, excessive spray valve movement, and significant temperature excursions below setpoint.

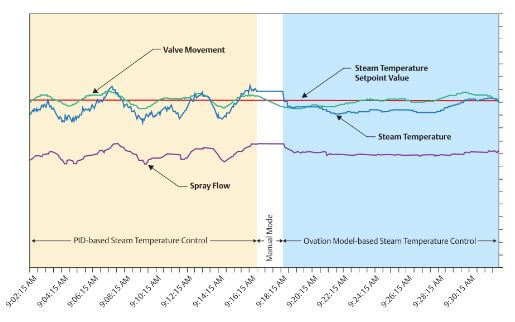

The cogeneration plant was controlled by an Ovation distributed control system (DCS). The boiler’s steam temperature steam temperature control was based on proportional-integral-derivative (PID) control. To address the issues associated with the changing load demands, the cogeneration plant staff connected with the Emerson team to find a better, more responsive control solution.

The project team identified model predictive control (MPC) as better way to provide more responsive and robust control. They used the Ovation Model-based Application for Steam Temperature Control, part of a suite of advanced, integrated solutions.

This advanced process control solution executes a step-response model that accurately reflects the relationships of controlled variables, manipulated variables, and disturbance variables to quickly and accurately achieve temperature setpoint.

This advanced process control solution executes a step-response model that accurately reflects the relationships of controlled variables, manipulated variables, and disturbance variables to quickly and accurately achieve temperature setpoint.

The overall strategy is to deliver optimal control of the boiler temperature by providing predictive control of changes in the heat release due to load, fuel BTU quality, radiant energy absorption, pass dampers, burner tilt, and spray valve performance. The model considers the current plant operating constraints and response factors and provides optimal results over the dispatchable range of load and operational characteristics.

As part of the project, valve tests were performed to check for seat erosion and to obtain flow characterization for linearization. This data was used to build a model for movement of the steam valve and its effect on changes in steam temperature.

The control strategy also addressed the concern about damage being caused by saturated steam entering the turbine. This concern was addressed on the superheat loops by integrating steam saturation priority-lower signals into the control logic.

Once the MPC controls were implemented and commissioned, the chemical manufacturer saw immediate improvements in steady-state operation, including the ability to quickly and accurately reach setpoint, and then maintain operation at the desired temperature.

Jeff noted that the big benefit was the reduced cycling of the valve and the associated maintenance reduction due to the extended time interval between repairs and rebuilds.

Watch this recorded webinar on ways to minimize the chance of tube leaks through better steam temperature control and visit the Steam Temperature Control section on Emerson.com for more solutions on improving overall steam production reliability and efficiency.