Emerson’s Marcelo Carugo and Marcio Donnangelo teamed with 4C’s Steve Probst to share ways that companies can improve safety & environmental regulation compliance performance in their digital transformation initiatives. Their presentation focused on an overview of how Digital Transformation is eliminating layers of complexity to bring pre–interpreted field data directly to those who need to make decisions and act.

They highlighted some examples. The first is in environmental reporting which involves flow measurements which must be verified to be accurate. Discovery of an inaccurate measurement can be costly for operators as they may pay fines from the last date that they can prove accurate measurement. Meter verification tools make it simple and convenient to prove accuracy over time. Operators can be notified of problems immediately to avoid misreporting and allowing for immediate corrective action.

Pressure relief valves (PRVs) are no longer isolated mechanical devices that rely solely on manual rounds as part of a preventive maintenance program. Release and leakage alerts can be wirelessly monitored, and then integrated into reporting and analytical systems. Powerful tools are now available to interpret these patterns and predict future releases before they occur.

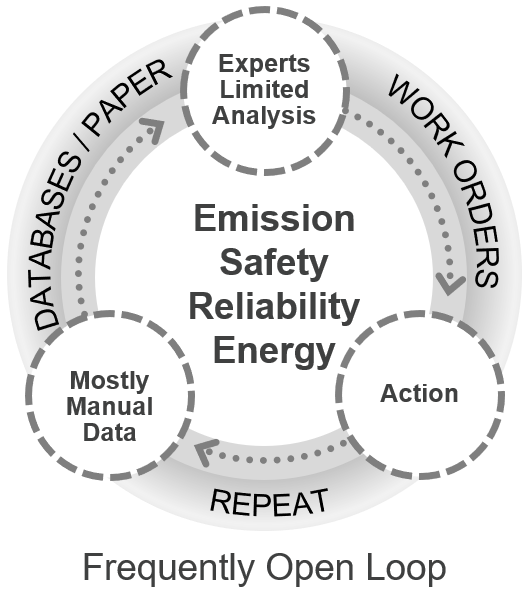

Process control has long been a closed loop process to keep the process operating within its intended range of operation. But main of the functions such as emissions, energy & safety reporting as well as reliability practices remain largely manual, open loop processes.

Process control has long been a closed loop process to keep the process operating within its intended range of operation. But main of the functions such as emissions, energy & safety reporting as well as reliability practices remain largely manual, open loop processes.

Operations have complex environmental & safety issues related to these open loops. Often downstream hydrocarbon processors face state and local fines from excessive flares.

These open loops are also tied to regulations such as OSHA CPL 03-00-021 National Emphasis Program (NEP) & Best Practice Response 29CFR 1510.151. Industrial Internet of Things technologies are enabling many of these open loop processes to move closer to closed-loop to drive improved performance.

This digital transformation toward closed-loop performance is deployed in four basic steps: data, connectivity, analytics and services.

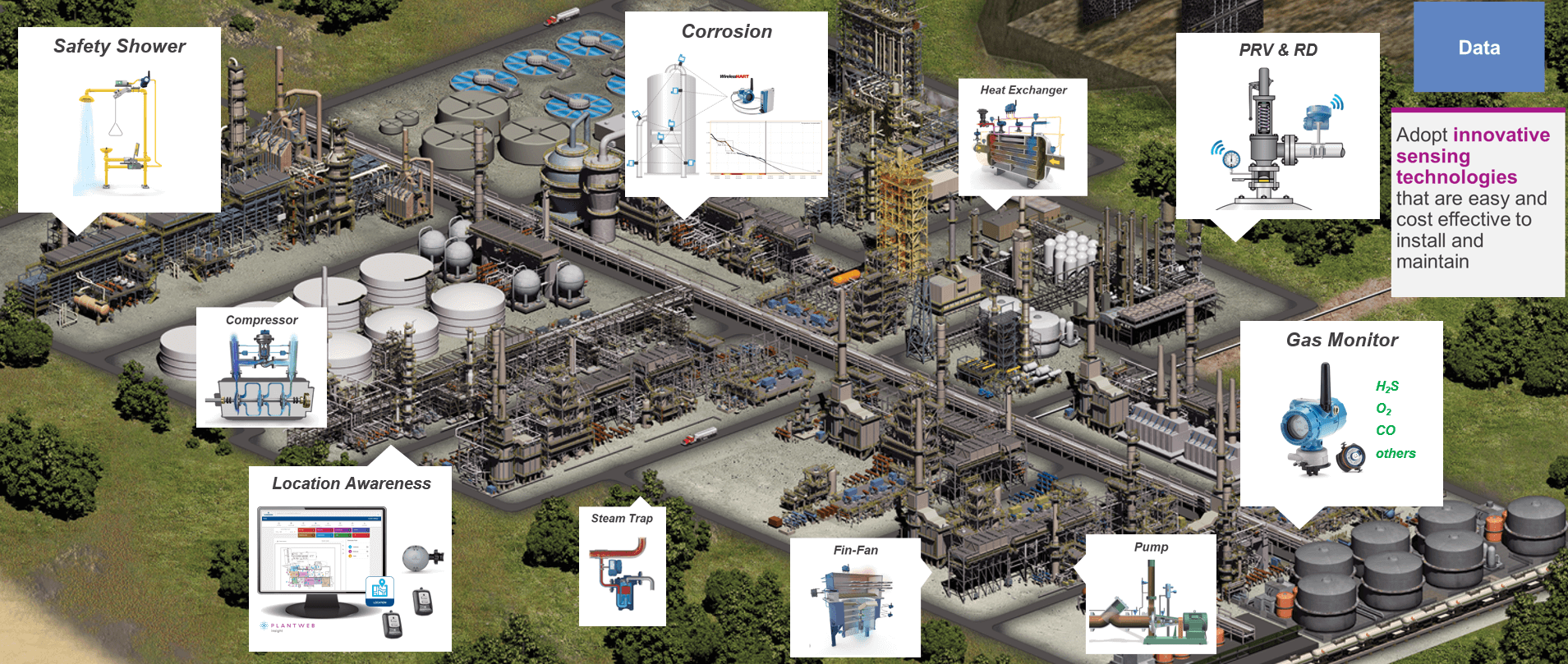

Enhancing data adoption involves innovative sensing technologies including wireless sensors that are easy and cost effective to install and maintain. With careful cybersecurity considerations, connectivity involves implementing a set of architectures that ensures security of operational data and allows secure interaction with IT and cloud applications.

Analytics—performed at the edge, on-premise, and in the cloud—are scalable applications to designed to deliver actionable insights and automate manual workflows. Services bring in the subject matter experts to deploy new monitoring solutions, consulting, and implementation services to help ensure operational outcomes in line with objectives.

Many non-control sensors have emerged to help close the loops in health, safety & environmental applications.

Marcio share some examples in closing the loop in safety practices. These include geofencing, safety mustering and safety alerts. Geofencing helps keep contractors safe and efficient with designated work zones. Keep workers safe by creating zones of known hazardous locations. Location awareness technology helps plants know that the personnel are safe and accounted for at designated muster points. Safety alerts, for example coming from safety showers or eye wash stations help plant personnel know where distressed personnel are located to quickly dispatch emergency responders.

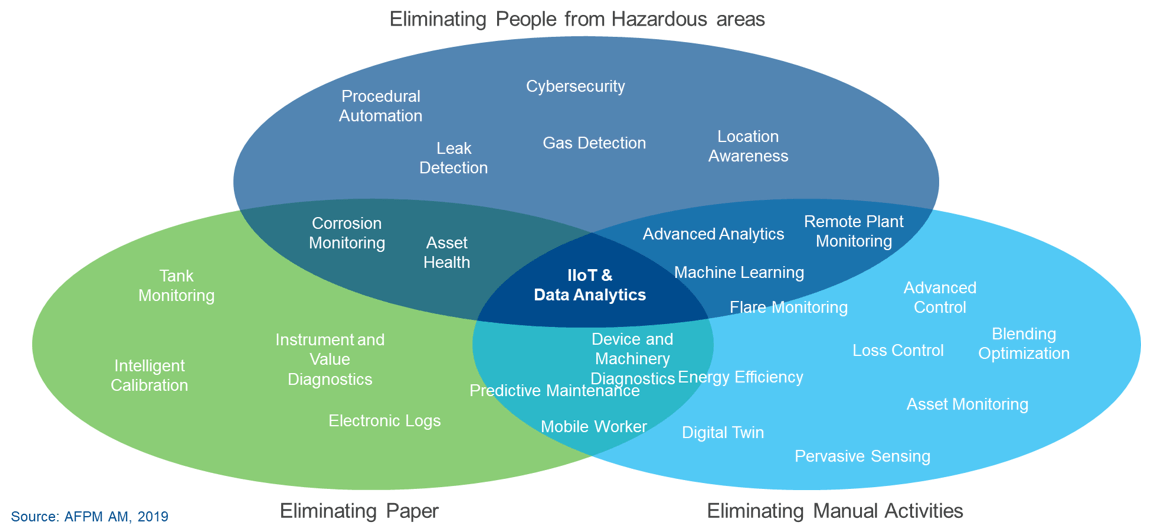

Marcelo showed 3 domains of digital transformation: paper elimination, manual activity elimination, and personnel in hazardous location elimination.

Visit the Digital Transformation section on Emerson.com for more on the technologies and practices to drive improved business performance. You can also connect and interact with other digital transformation experts in the IIoT & Digital Transformation group in the Emerson Exchange 365 community.