Operators are the heart of any process. Experience, skill, and attentiveness give the best operators an intuitive feel for processes that helps ensure uptime, safety, repeatability, and quality—even in the most infrequent process situations. But with a major shortage of skilled personnel, plants find themselves needing to maintain exceptional performance and safety while simultaneously helping new operators gain experience.

In an Emerson Exchange Virtual Series presentation, Michael Jiang, senior innovation program manager at INVISTA, joined Emerson’s Pierce Wu and Dustin Beebe to share the story of how INVISTA used state based control (SBC) to empower operators.

The risks of the status quo

Pierce Wu, Emerson’s business development manager, shared some striking statistics surrounding the challenges operators across a wide range of industries face in the plant:

- 70-85% of existing operational procedures are incorrect or incomplete

- 42% of unscheduled plant shutdowns are caused by operator error

- 70% of incidents occur during abnormal situations such as startup and shutdown

These errors can amount to production losses of nearly $80 million per major incident an organization experiences.

Operator training is key to solving these problems, but incorporating SBC also helps organizations bridge the skills gap in the meantime, helping processes perform better today, and upskilling operators even as they train. Pierce explains,

Even with a control system in place, most plants’ production still relies on board operators to conduct a massive amount of manual procedures for startup, shutdown, upset recovery, and emergency shutdown.

These manual inputs required from board operators are complicated by the distraction caused by alarm floods. All of these factors complicate the already difficult decisions board operators need to make in order to avoid safety and quality issues. Pierce explains how automation can lend these stressed operators a hand,

State based control or procedural automation with alarm management can enter the picture as a great technology to support our operation group… by eliminating manual procedures and automating them in the control system.

Automated SBC logic monitors process variables so board operators can focus on other key items that really need their attention. It also ensures best practices are consistent across all operators, regardless of experience level.

Real world results

Michael Jiang shared how digital transformation centered on SBC has changed the game for INVISTA. Materials created using INVISTA specialty chemical intermediates can be found in nearly every aspect of life. This wide reach leaves INVISTA with a lot of responsibility—the organization must safely, quickly, and reliably deliver its products to customers all over the world.

INVISTA’s comprehensive SBC solution was critical to this ability to ensure safety, reliability, and quality. The plant’s whole operating cycle is covered in the SBC design including:

- Startup

- Shutdown

- Process idle

- Emergency handling

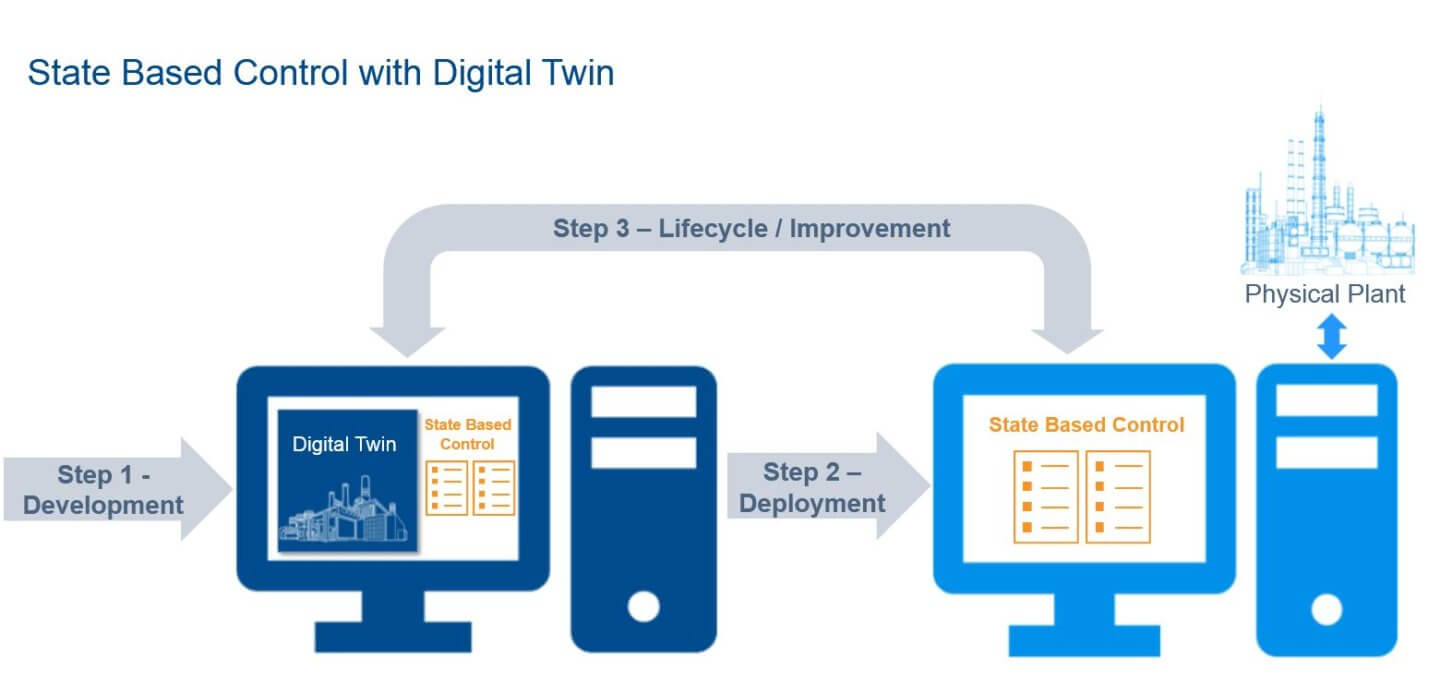

- Vessel switches

Michael explains how SBC has served as a control complex to make all control scenarios automated. INVISTA’s SBC engages about 400 control modules, which translates to 1200 I/O points and 83 PID controllers. The team also uses dynamic alarming and a digital twin to build a comprehensive digital solution to help operators make better decisions.

Getting all the system working together really elevates the traditional process control into the next level process management. All of our process knowledge will be captured and maintained in this sustainable cycle to create continuous value.

INVISTA saw a number of impressive results from its digital transformation initiative:

- Increased operating discipline

- Nearly 80% reduction in process intervention

- Approximately 90% reduction in alarm rate

- Reduction in unplanned events

Making SBC a reality

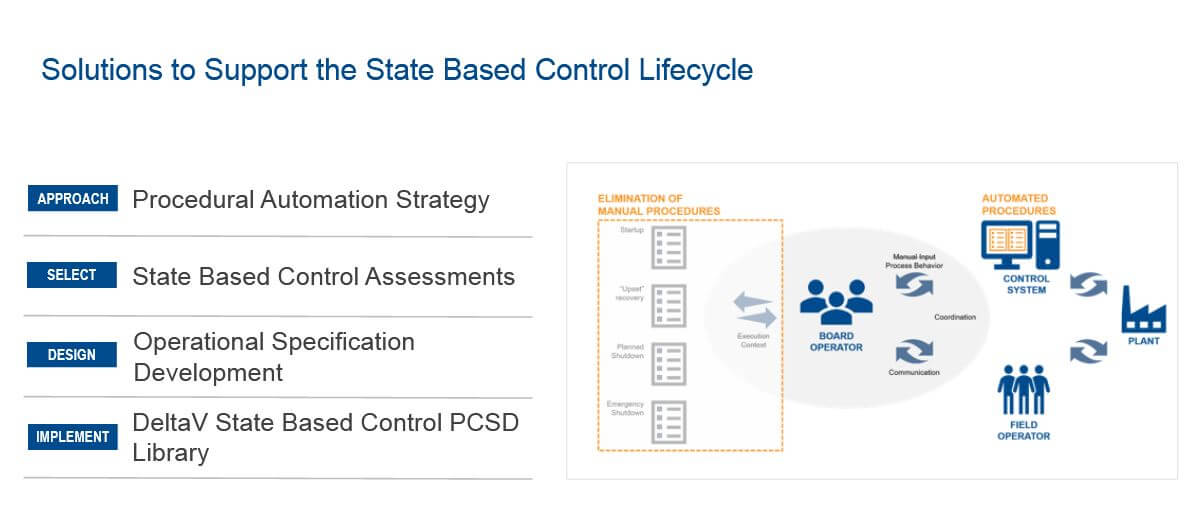

Emerson’s vice president of control and operator performance, Dustin Beebe, shared the importance of approaching SBC implementations with a clear procedural automation strategy in mind. Emerson helps customers identify what it would take to implement SBC and helps determine toolkits, processes, ownership structures, and implementation strategies to achieve the greatest benefit and ROI.

Emerson offers a robust toolkit for SBC that helps customers easily maintain SBC across the lifetime of the facility and implement strategies easily. SBC delivers the most value when coupled with Emerson’s Dynamic Alarm Management to reduce alarm floods and nuisance alarms, fully freeing operators to concentrate on issues that truly demand their attention.

We’re facing many challenges in our facilities today… One of those is operator error. With state based control we’re looking to really improve operational discipline and minimize operator errors.

To learn more about the benefits INVISTA gained implementing state based control, you can view the entire presentation on demand by registering for Emerson Exchange. And while you’re here, please take a moment to comment below on how you empower your operators to improve performance and safety in normal and abnormal situations.