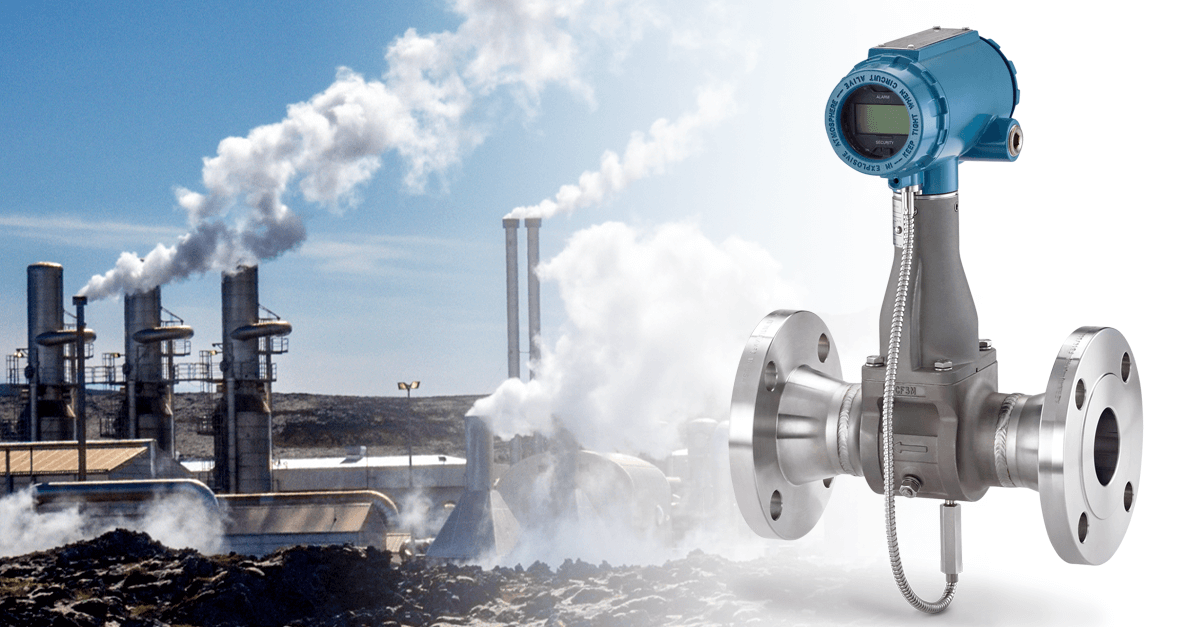

Vortex flow measurement is uniquely adaptive when it comes to handling difficult applications. By virtue of its science, utilizing the von Kármán effect, these instruments are accurate across a wide operating range and effective at withstanding high process pressures and temperatures. In this post, we’re highlighting the latest in our 8800 Flow Meter product portfolio – the MultiVariable Vortex Flow Meter. Designed with superheated steam applications in mind, we’ve combined proven temperature and flow measurement technology into one powerful device. With this MultiVariable meter option, we can deliver better control, reliability, and safety in today’s demanding steam operations.

Let’s Talk Steam

We’ve talked before about the unique challenges of measuring steam applications and how Vortex flow meters are particularly well-suited for measuring saturated and superheated steam applications. Another challenge with steam applications is how its density can fluctuate depending on the temperatures and pressures of a process. Volumetric flow rates are a measurement of the space a liquid occupies as it is flowing. For steam, volumetric flow rates don’t represent the most accurate measurement of its flow because of this constantly shifting density. A more accurate representation for steam applications is mass flow rate, the measurement of the mass of the fluid as it flows. Operators benefit from flow meters with multivariable capabilities that can provide them with compensated mass flow readings as process temperatures and pressures change.

Our MultiVariable Vortex Flow Meter has an integrated temperature sensor within the meter body. This thermowell is incorporated inside of the vortex meter’s shedder bar to capture process temperatures without adding additional leak points to the all-welded meter body design. It eliminates the need to install and maintain a separate measurement point for temperature. We can now account for fluctuations in density to provide operators with a highly accurate mass flow rate in demanding steam applications.

The Problems with Integrated Pressure Sensors

We’ve engineered our MultiVariable Vortex Flow Meter to measure temperature along with volumetric flow rates to deliver the most reliable flow measurements for steam applications possible. We’ve designed it to pair with a separate transmitter to receive pressure data via a HART® pressure device like the industry-leading Rosemount 3051S Pressure Transmitter. Together, these instruments ensure a trustworthy compensated mass flow measurement.

When pressure sensors are integrated into the vortex flow meter along with temperature sensors, additional processing piping and meter body penetration is needed to support the integrated pressure sensor. This exposes the end user to the potential of plugging and clogging of process piping and safety risks of additional leak points. It also makes new vortex installation more complicated, risking improper process sealing, damage to the seal, and escaping fluids when the flange connection is opened. If the pressure module is integrated directly into the meter body, the electronics of the pressure sensor are more prone to failure from high temperatures due to the close proximity to the process piping. We’ve found that these meter designs introduce too much potential for installation issues, measurement errors, and inconsistency overall.

The Advantages of Installing a Rosemount 8800 MultiVariable Vortex Flow Meter

Emerson’s MultiVariable flow meter utilizes external pressure measurement to take full advantage of the benefits of vortex technology. The all-casted, all-welded body eliminates ports, crevices, and gaskets for clog-free functionality. Real-time temperatures and pressure measurements are measured or received by the electronics inside the transmitter to perform the calculations necessary for compensated flow measurement. The integrated removable temperature sensor is isolated from the process and separate from the vortex sensor which facilitates independent verification or replacement of each sensor without breaking the process seal.

Today’s steam operations need more reliable instrumentation to meet the demands of high temperatures and pressures while maintaining the highest levels of plant safety. We’ve engineered our solution to meet these critical needs and provide the insights our customers need to continuously improve their optimization and energy balance strategies. Learn more, link.