Emerson’s Warren Merriman presented Minimizing VOC Emissions During Tank De-Watering at the 4C Health, Safety & Environmental conference. Here is his presentation abstract:

Over time, water separates and collects in tanks and needs to be removed. Manual or other methods of controlling the water draw-off can result in excessive hydrocarbon product in the discharge to the sewer system. This session will review a unique solution to reduce the amount of Hydrocarbon, including colorless Benzene, released to the Effluent System during Tank De-Watering events.

Results have shown reduction of VOC breakthrough measuring less than 1 gallon of hydrocarbon per draw-off event, minimalizing safety concerns of operator exposure, and helps overall plant mass balance data for Yield Accounting.

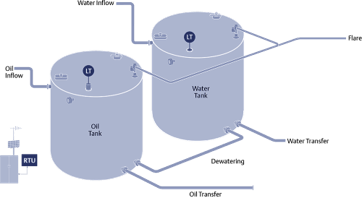

Warren opened describing tank dewatering. Storage tanks hold hydrocarbon feedstocks, intermediates and finished products. Over time, water separates and collects in the tanks. Water is drained from storage tanks reducing corrosion and potential process problems.

Warren opened describing tank dewatering. Storage tanks hold hydrocarbon feedstocks, intermediates and finished products. Over time, water separates and collects in the tanks. Water is drained from storage tanks reducing corrosion and potential process problems.

Manual or other methods of controlling the water draw-off can result in excessive hydrocarbon product in the discharge to the sewer system. This poses a potential process safety risk, increased operator exposure to VOC, and mass balance inaccuracies – i.e., accounting water for product.

Some operational challenges include when operations manually oversee the de-watering process, closing a manual valve once hydrocarbon withdrawal starts to occur. Some hydrocarbon products resemble water such as Naphtha.

Unacceptable levels of hydrocarbons can be released to the sewer causing VOC emissions which can place operators in harm’s way. These VOCs are harmful to the effluent system and can possibly result in fines.

The other possibility is leaving too much water in the tanks which cause mass balance issues and benchmarking requires .5% plant-wide mass balance accuracy.

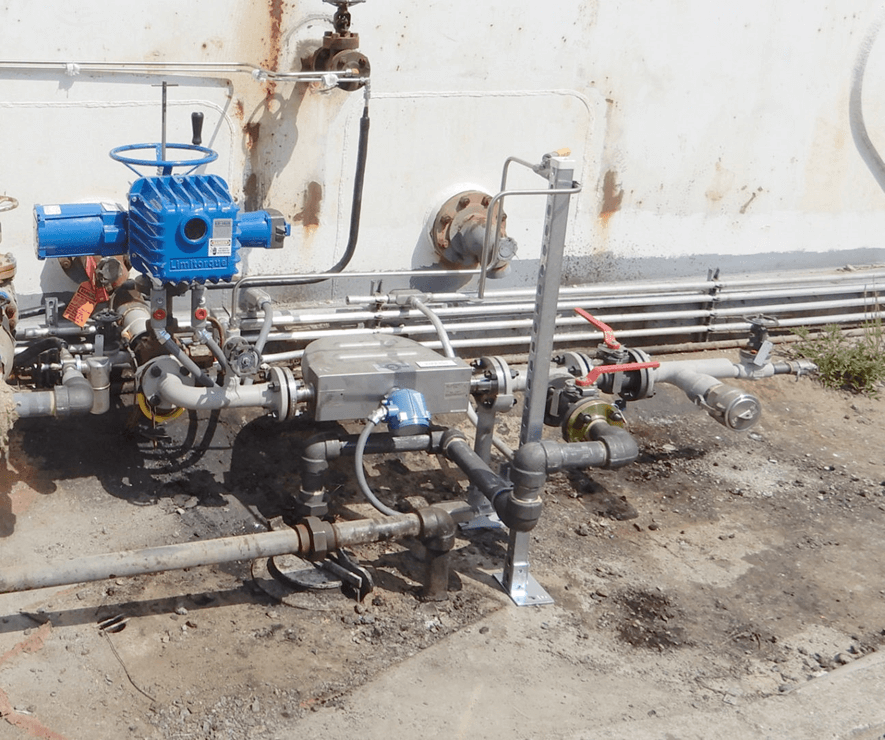

Warren shared a solution for automating the tank dewatering process. By using Micro Motion Elite Coriolis mass flow and density meters which as highly accurate, mass balance measurements can meet the accuracy requirements. Micro Motion 2700 Multivariable Flow and Density Transmitters accurately detect the presence of hydrocarbons at ~ 5% break through to activate a light or trigger a motor-operated valve (MOV) to close. A wireless THUM feeds the data from the flow meter—mass flow, density, temperature, smart meter verification and totalizing.

Warren shared a solution for automating the tank dewatering process. By using Micro Motion Elite Coriolis mass flow and density meters which as highly accurate, mass balance measurements can meet the accuracy requirements. Micro Motion 2700 Multivariable Flow and Density Transmitters accurately detect the presence of hydrocarbons at ~ 5% break through to activate a light or trigger a motor-operated valve (MOV) to close. A wireless THUM feeds the data from the flow meter—mass flow, density, temperature, smart meter verification and totalizing.

The transmitter performs a specific density calculations and set’s a limit for 95% water and 5% hydrocarbon breakthrough. When the limit is reached, the control system sends a shutdown signal to the MOV.

The refiner who implemented this solution removed variations between the process and operations with less than 1 gallon of hydrocarbon per draw-off. This automation solution eliminated the major safety concern of operator exposure to VOCs. It greatly affected effluent environmental performance and improved inventory measurements for mass balance. They have implemented this solution on 25 tanks with 16 more under evaluation for addition. The design is simple and easy for operations to use.

Visit the Coriolis Flow Meters for Mass, Volume, & Density section on Emerson.com for more on the technologies and solutions to drive safer, more efficient tank dewatering operations.