An article, Strategic Approach to Automated Leak, Rupture Detection, was published in the June 2021 edition of Pipeline & Gas Journal. A summary of the article, delving into the potential consequences of unrecognized pipeline leaks and ruptures, goes into why methods of detection, analysis of risk, and systems innovations should be viewed as a priority.

Authors: Paul Dickerson, Global Products Leader & Phanindra Kanakamedala, Product Manager

Oil and gas pipeline leaks and ruptures require rapid response. Undetected leaks or ruptures left unchecked or neglected for an inordinate amount of time, no matter how minute or critical, could spell disaster. Humans, the environment, and corporate reputations could all be harmed.

There have been examples of unrecognized liquids pipeline leaks and gas line ruptures resulting in damage to sensitive areas, including a rupture caused by a backhoe strike—killing two workers in 2019. The new Protecting our Infrastructure of Pipelines and Enhancing Safety (PIPES) Act of 2020, among other regulations, has been developed with more rigorous requirements.

Methods of detection, analysis of risk and systems innovations are as important or more important than ever.

Detection Paradigms

Changes in industry coupled with the global acceleration toward decarbonization have resulted in new, technologically advanced schools of thought revolving around leak-and-rupture detection strategies. To sustain a successful automated leak-detection paradigm, we need to have common integration with field instrumentation—and tools to accelerate how quickly a leak can be detected. Automation technology is one answer.

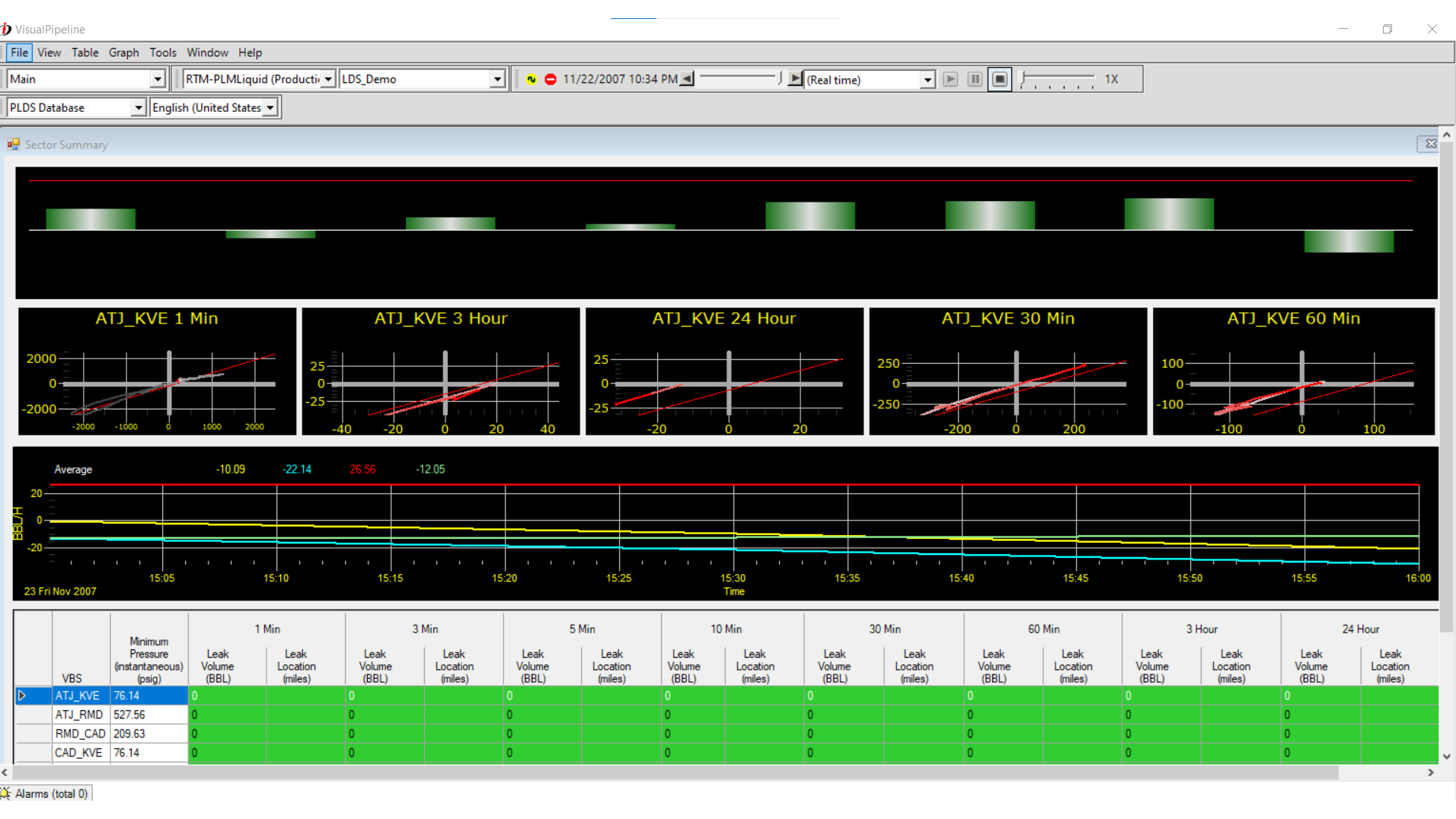

PipelineManager software with advanced, real-time transient model (RTTM) based simulation. Click to enlarge.

Advanced, real-time transient model (RTTM) based simulation is part of Emerson’s PipelineManager™ software; it compares a digital twin against real pipeline operations. By detecting deviations from what’s expected within the pipeline—versus what’s indeed being measured to offer guidance and help improve the situation—ensures the automated software better informs.

Gas and liquids pipelines operators have unique scopes and diverse energy products, along with varying shipping and operational philosophies. Pipeline parameters are important and must be considered as part of any leak and rupture protection strategy, in addition to how pipelines are categorized. The location of a pipeline is key, due to the probability of proximate environmental changes that could impact analysis in the future. A certain level of maintenance and upkeep is also required due to inevitable changes in the physical properties of a pipeline.

With the appropriate instrumentation and communication methods—and an available SCADA system or distributed control system (DCS)—integrated, automated leak-detection solutions offered by Emerson can present a formidable solution. PipelineManager acts as an umbrella and solves a specific part of the problem; providing robust, reliable and highly accurate leak detection, at the same time acting as a catalyst to help forecast future performance.

This aligns with the systems-thinking approach necessary to keep all facets of a pipeline’s operation in full tune.

Limitations are sometimes based on the absence of available bandwidth for communications or the quantity of data that can be feasibly handled. If an RTTM-based solution isn’t practical for a given operation, LeakSentinel™ software offers a more cost-efficient, low-maintenance, plug-and-play solution. It is easy to deploy yet still provides compliant leak detection when the pipeline lacks the instrumentation required by an RTTM-based solution.

Automation Driven

Technologies related to plume detection and fiber-optics for real-time anomaly detection reflect the outcroppings of a move toward automation and the industry’s embrace of pipeline integrity management programs that are accessible, easy to use, and provide ongoing risk analysis. Emerson’s high-consequence area (HCA) analysis solutions and risk-modeling software, for example, takes users to the next level; aggregating data from across the organization to produce customizable risk-environments.

This is one piece of a robust leak management and pipeline integrity program. The Emerson suite of advanced software includes PipelineManager, LeakSentinel, which uses machine learning and artificial intelligence to improve sensitivity, and RuptureSentinel™.

Each is designed to meet specific needs in various parts of the automated detection value chain—from oil and gas, water, chemicals, and newer energy products and blends. When pipeline operators need to be alerted of major events within seconds—not minutes or even hours—RuptureSentinel™ offers near real-time detection, providing near 100% reliability in the event of a pipeline rupture.

New Capacities

Hydrogen—and its lower energy density—poses a greater risk of release than natural gas and will require greater storage capacity. More pipelines and terminals will be needed in light of shifting energy demands, the pursuit of emissions minimization and strides toward global decarbonization. The critical nature of such infrastructure will continue to be relied upon during the global economic transformation that is occurring. Investing in the future of aging pipelines and the development of new networks and systems will equate to future growth.

Internal automated leak-and-rupture detection offers comprehensive protection as part of an optimized pipeline-management strategy. Methods of inspection vary, sometimes working in tandem, and can be appropriately categorized based on performance requirements. The aggregation of data points can be managed strategically and with much greater efficiency, leading to higher standards of accuracy, reliability and robustness as part of an overall solution.

LeakSentinel integrates with flexibility and has a small application footprint. It interfaces easily with control room applications, demonstrating the ability to detect leaks with minimal instrumentation and less configuration. RuptureSentinel uses quality data to rule out false positive alarms and allows teams to be notified immediately, boosting the confidence of operators to act decisively. These solutions can stand alone or be fully integrated with PipelineManager.

Vigilance is always key to keeping everyone safe, complying with regulations, safeguarding the environment, and maintaining an untarnished public image. Our Emerson experts can help you assess and determine which leak detection tools are the best fit for your specific needs.