As oil and gas producers balance the demands for greater production and more sustainable operations, reducing fugitive emissions is one area of focus. The packing in valves is one area to drive improvements.

In a Processing article, Simplifying control valve packing selection, Emerson’s Sarah Witte and Wade Helfer highlight the importance of valve packing selection for more sustainable production.

Sarah and Wade open noting the traditional focus on valve characteristics and not packing.

The traditional valve selection process has historically involved choosing a valve design based on flow performance, material compatibility, pressure and temperature capabilities, and related factors. Control valve packing selection was often a relatively minor issue, based largely on the process temperature.

They describe the role of valve packing.

They describe the role of valve packing.

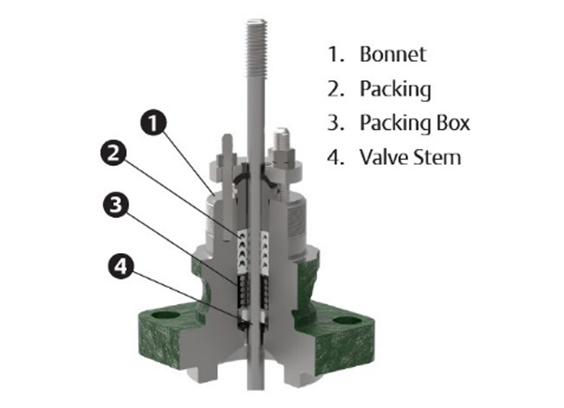

A sliding stem valve has a rod protruding from the body that rises and falls to open and close the valve. A rotary valve has a shaft extending out the side of the valve that is connected to a ball, disc or plug. As the shaft turns, the rotary valve opens and closes. In either case, the valve stem must exit the body and be capable of relatively friction-free movement, while containing the process and avoiding leaks. Valve packing makes that possible.

Sarah and Wade explain how valve packing works.

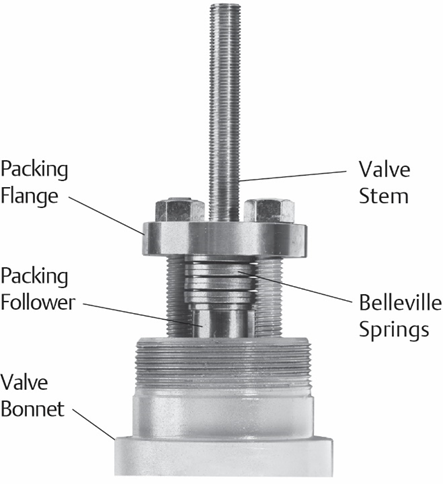

The sealing portion of a valve packing usually consists of a series of Teflon (PTFE) or graphite rings that encircle the valve shaft (Figure 1). The rings are compressed with a combination of a packing follower, packing flange and bolts — which push down and squeeze the packing rings against the shaft to seal against process leaks.

…designs were simple, and so was packing ring selection, as it was primarily based on process temperature since only very high process pressures impacted packing. All that changed when fugitive emission reduction became a priority for the EPA [U.S. Environmental Protection Agency]. Valve packing emissions for hazardous and targeted chemicals were initially capped at 500 PPM but have been steadily dropping with each round of regulation. Packing design options are now much more varied, complicating the selection process.

To address these tighter emissions standards:

…packing must be “live loaded” to keep constant pressure on the sealing rings… This is usually accomplished using spring-loaded Belleville springs, which are compressed during installation. The Belleville springs maintain a constant force on the packing, ensuring it seals over time, even as the rings wear from stem movement. The loading of the packing must be higher than the process pressure, which further complicates the design and selection process.

Read the article for some valve packing materials to meet the stringent fugitive emissions standards, including PTFE, graphite, and a graphite & PTFE combination advanced environmental packing arrangement. Also, Sarah and Wade address high-temperature modeling and provide a packing selection considerations summary in the article.

Visit the Fisher ENVIRO-SEAL Control Valve Packing Systems page on Emerson.com for more on ENVIRO-SEAL and HIGH-SEAL live-loaded packing systems for sliding stem and rotary valves that deliver exceptional stem sealing capabilities.