The three key components in a safety instrumented function (SIF)—sensor, logic solver and final element—each have their own probabilities of how they will perform, or not perform, when called upon to bring the process to a safe state. Of these three components, the final element is more like to fail on demand due to its role in touching the process and mechanically operating.

In a Hydrocarbon Engineering article, Improving safety shutdown valve reliability, Stanley Amirthasamy and Emerson’s Lura Parrent share ways to improve the reliability of final elements when they are safety valves. They open noting how safety valves are used to bring a process to a safe state.

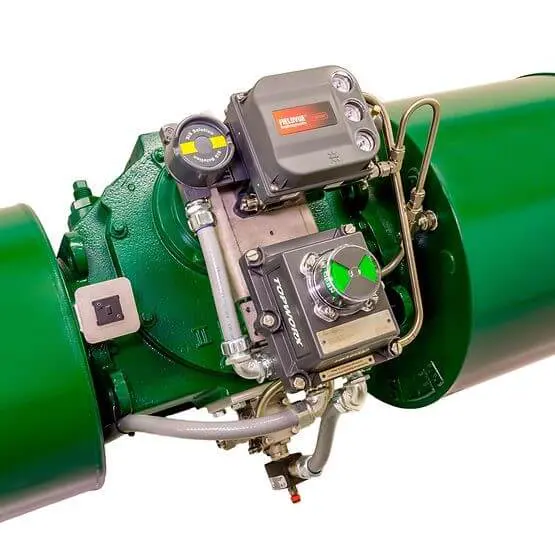

The final elements are usually valve assemblies, but can be pumps or motors. Valves are typically closed to isolate equipment, stop raw material feeds, or block steam to turbines. They may also be opened to vent reactors, divert gases to a flare, or perform other actions.

Stanley and Lura describe the safety concept of probability of failure on demand.

SIS calculations are used to determine the probability of failure on demand (PFD) – and the sensors, logic solver and final elements are chosen to satisfy the desired level of risk reduction. The probability of failure is driven by the reliability of the device and the frequency of proof testing. If the device is proof tested more frequently, it can be less reliable since a failure will be detected quickly. If proof test intervals are long, then the device must be much more reliable to ensure it will perform when called into service.

They note the problem with valves as the final element in the SIF.

They note the problem with valves as the final element in the SIF.

They have constant contact with the process media, usually employ few diagnostics, and are typically only operated in the event of a safety incident. This means that years can elapse without operation. It is also difficult to test valves because, by design, their operation will often shut down the process. For these reasons, plants have a strong incentive to improve the reliability of the final element valves in a SIS and find ways to test valve operation without a plant shutdown.

Simplicity is important in increasing reliable performance.

Recently, high-volume smart positioners with extensive diagnostics [Fisher DVC6200 SIS digital valve controller] have become available. These positioners incorporate a host of design improvements, including multiple diagnostic sensors, and embedded partial stroke test capability – along with high air flow capacity to eliminate the need for a volume booster.

Read the article for more on local trip reset and partial stroke testing, ways to improve final element reliability, and how to extend proof test intervals. Visit the Digital Valve Controller section on Emerson.com for more on ways to drive improved performance in safety, reliability and efficiency.