In their recent article in Plant Engineering, Emerson’s Claudio Fayad and Erik Lindhjem share that selecting plant control and reliability technologies is no longer a matter of convenience. Rather, project teams have shifted focus to delivering increased value across the technology lifecycle. The cloud, it seems, has changed everything. Plants today operate very differently than they did just ten years ago, and much of that change is focused on connectivity. Erik and Claudio explain,

“As the many layers of the Purdue model of industrial engineering have flattened in the cloud and edge computing age, connectivity has become more important. Today, forward-thinking process manufacturers are making automation decisions with an enterprise IT mindset, moving away from a collection of local systems to a single system that is deployed everywhere.”

Cloud connectivity for automation technologies helps OT teams keep a better finger on the pulse of operations.

Breaking silos

While information technology (IT) groups were quick to transition from disparate technology strategies to a more centralized, corporate infrastructure, operational technology (OT) has been slower to make that move. The result has been a siloed OT infrastructure where data is trapped in different domains and plants across the enterprise. And while standalone edge gateways have helped teams begin to break down those silos for increased data democratization, the best solution will always be a more holistic automation strategy using an integrated platform. This strategy is at the heart of Emerson’s boundless automation architecture and begins to illustrate just what the future will hold for automation. Claudio and Erik explain,

“Building an edge infrastructure brings data together but does not fundamentally solve the problem of local disparities due to legacy technology use in each plant. Instead, thinking about automation systems on an enterprise level—the same way IT teams view solutions like Oracle and SAP—unlocks more value by creating a single, standardized automation platform across the whole corporation.”

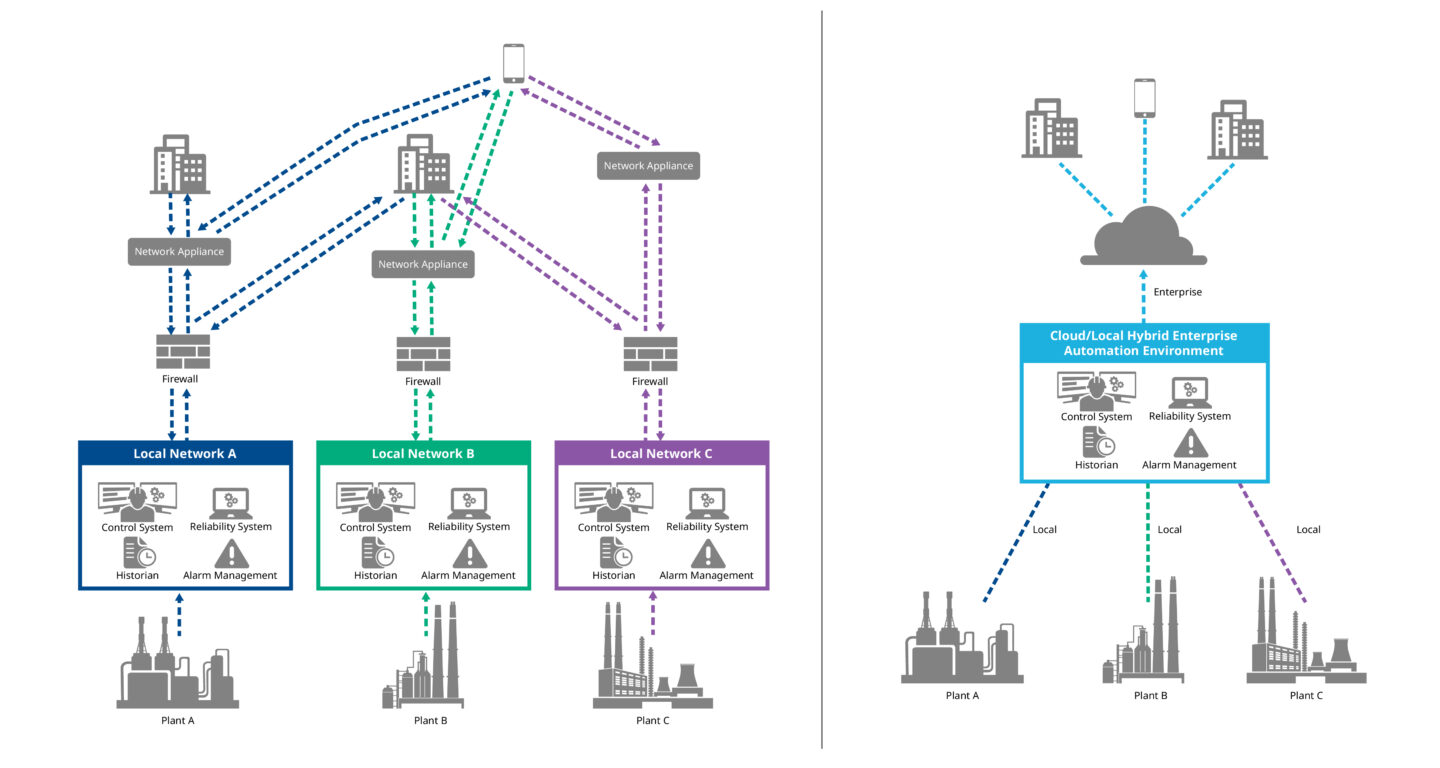

Looking at the image below, we can see how this is true:

A single enterprise automation environment eliminates the complex connectivity webs that can get in the way of collaboration and performance improvement.

On the left, multiple plants are using individual, siloed networks to send data to a wide array of systems and devices at the enterprise level. The result is a complex web of communication—one that must be maintained and secured at each junction. When cross-functional teams want access to data from multiple domains, they must traverse this complex web to find it. Assuming they find it at all, the data they collect is often in a wide variety of formats and hard to sort, store, and analyze.

Moving to a cloud and local hybrid enterprise automation environment (like the one in the right-hand image) democratizes data by standardizing it while maintaining—or in some cases, even adding—context and knowledge, making it easier to combine information in a way that makes sense to end users. According to Erik and Claudio,

“In such a scenario, the right information is always available to the right people hassle-free, enabling personnel with the right credentials to easily and securely access data for fostering insights.”

And those insights are key. They’re what drives innovation.

How do we get there?

Big changes take time, and a holistic strategy toward automation and reliability will not happen overnight. However, focusing on automation at the OT/IT convergence is not a project that teams will have to tackle alone. Exemplified by Emerson’s boundless automation strategy, the most forward-thinking automation suppliers are creating industrial architectures to integrate operations through next generation automation systems that integrate multiple operational domains. These solutions effortlessly move data from the field to the edge and into the cloud for peak optimization across the enterprise.

The technologies to accomplish this transition to holistic automation aren’t all in place today, but they’re coming—and soon. Partnering today with automation experts focused on that seamless future will help ensure your team is ready when transition becomes tradition.

You can read more about how control systems are evolving to better meet enterprise and operational needs by reading the article in its entirety at Plant Engineering.