Effective quality assurance processes are essential in pharmaceutical and biopharmaceutical manufacturing processes. Deploying Process Analytical Technologies (PAT) is one way these manufacturers have driven business improvements.

Pharma Manufacturing magazine’s Pharma Innovation Awards highlights the technologies and systems driving improvements across manufacturing operations. Their December 2022 article, Pharma Innovation Awards 2022, shares the winners for the year.

One of the winners is DeltaV Spectral Process Analytic Technology (PAT) which helps pharma and biopharma manufacturers drive quality improvements. Here is the article’s description of DeltaV Spectral PAT.

One of the winners is DeltaV Spectral Process Analytic Technology (PAT) which helps pharma and biopharma manufacturers drive quality improvements. Here is the article’s description of DeltaV Spectral PAT.

Reducing the risk of contamination, as well as reducing quality assurance and compliance burdens, is an ongoing quest for pharma manufacturers. Few industries have higher quality control stakes than pharma. When at the other end of a product there is a patient whose life might depend on it, there is no margin for error. And while achieving higher quality is sometimes associated with cumbersome procedures, this year’s winners prove otherwise.

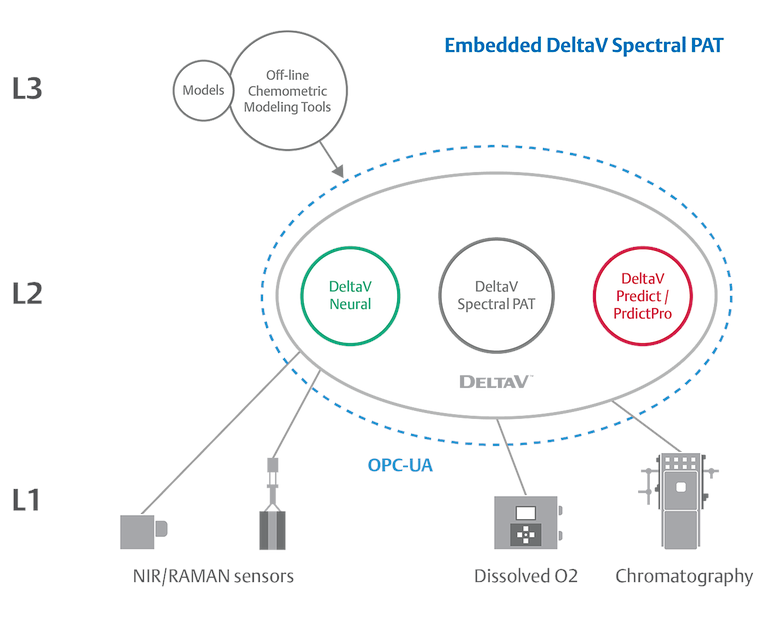

Our first winner is Emerson’s DeltaV Spectral Process Analytic Technology (PAT), a closed-loop process control system that enables fully automated production, reducing manufacturing variability by seamlessly embedding the PAT process into its controls.

The DeltaV Spectral PAT is being recognized for its ability to collapse the traditional layered PAT approach, deploying embedded PAT in real time, and simplifying the maintenance of closed-loop process control. According to Emerson, their design dramatically reduces the quality validation process and removes the risk of human error entirely.

Additionally, the system’s integrated environment makes it easier for users to implement and maintain, as they can monitor multivariate data from the interface used to perform all other control steps.

The solution was a favorite among Pharma Manufacturing’s reviewers, with one reviewer commenting that it will “significantly impact continuous manufacturing PAT processing.”

Automating quality control can help manufacturers decrease both waste and cost.

Visit the DeltaV Spectral Process Analytic Technology (PAT) section on Emerson.com for more on how this application brings stability and performance by bringing spectral waveform data directly into the control system. By implementing in-line, real-time, continuous, closed-loop process verification and control with an automated real-time quality release, manufacturers build a foundation for better regulatory management more easily while optimizing facility performance and throughput.