Emerson

Automation Experts

Featured Posts

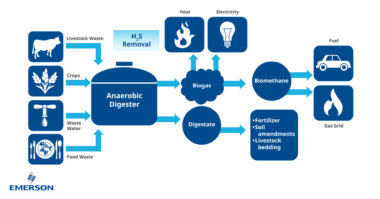

Process Gas Analyzer Strategy for Refining Biogas April 16, 2025 | Oil & Gas, Sustainable Energy Adopting more renewable fuels is one of the paths to reducing carbon emissions, especially when they can be made compatible with existing distribution infrastructure. Renewable diesel is an obvious example, but there are also growing opportunities for renewable natural gas (RNG) made from a variety of sources, including agricultural wastes. Of course, digester gas from… Read More

Process Gas Analyzer Strategy for Refining Biogas April 16, 2025 | Oil & Gas, Sustainable Energy Adopting more renewable fuels is one of the paths to reducing carbon emissions, especially when they can be made compatible with existing distribution infrastructure. Renewable diesel is an obvious example, but there are also growing opportunities for renewable natural gas (RNG) made from a variety of sources, including agricultural wastes. Of course, digester gas from… Read More The Growing Sophistication of Instrumentation Makes In-House Servicing Less Practical. Here’s an Alternative. April 16, 2025 | Chemical, Downstream Hydrocarbons I work with a lot of engineers and other mechanically minded people, but I don’t know many that work on their own cars. Maybe an oil change here or there, but the sophistication of today’s engines and internal networks makes DIY work so impractical that it really must be left to specialists. The same idea… Read More

The Growing Sophistication of Instrumentation Makes In-House Servicing Less Practical. Here’s an Alternative. April 16, 2025 | Chemical, Downstream Hydrocarbons I work with a lot of engineers and other mechanically minded people, but I don’t know many that work on their own cars. Maybe an oil change here or there, but the sophistication of today’s engines and internal networks makes DIY work so impractical that it really must be left to specialists. The same idea… Read MoreLatest Posts

Introductory Electric Valve Actuator Video Series

Here you can find an excellent introductory video series on electric valve actuation. The series begins with the basics and explores operation, technology, control, monitoring, and diagnostics.

Machine Learning and AI for Optimizing Operations

Rick Kephart, Morgan Lewis, Michael Painter, and Zitara’s Evan Murphy led a session titled “What is Your Power Play? Winning with AI and Machine Learning Solutions” at the Emerson Exchange 2025 Conference.

What Type of Cyber Defender Is Your OT Team?

We’ve talked a lot in this space about how cybersecurity is a particularly difficult challenge for OT teams. For decades, OT systems were specifically engineered to be closed to the outside world and from one another to ensure secure, reliable operation. That trend...

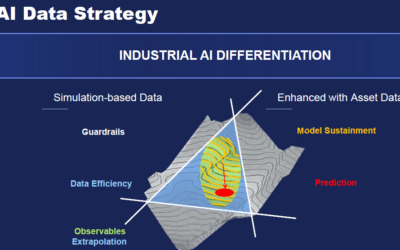

Industrial AI for Asset-Intensive Manufacturers and Producers

Heiko Claussen, Chief Technologist with Emerson’s Aspen Technology business, presented, Industrial AI in Asset-Intensive Companies Brings Agility, Guidance & Automation, at the Emerson Exchange 2025 Conference.

Top 4 Sustainability Challenges in Utility and Water Management for Mining

Addressing sustainability challenges in utility and water management in mining is crucial for ensuring the long-term viability of resources and meeting both regulatory demands and community needs. Below are the top four challenges in this sector: Water Scarcity and...

Enhance Water Management and Utilities in Mining with Emerson’s Innovative Flow Technology

Managing water efficiently is crucial in mining—any uncertainty can lead to elevated costs, safety and environmental risks, and operational inefficiencies. Emerson's advanced flow technologies, including the Flexim Non-Intrusive Ultrasonic Flow Meter and the...

Meet Our Bloggers & Experts

Jim Cahill

Chief Blogger, Social Marketing Leader

Todd Walden

Author and Blogger

Systems & Software

Erianne Ferrer

Senior Analyst, Social Media

Discrete Automation

Jonas Berge

Senior Director, Applied Technology

Kelly Albano

Marketing Product Manager

Popular Posts

Want to get in touch?

Please do, our experts are here. Contact us so we can continue

the conversation.

Stay up to Date with the Latest News and Updates

Follow Us

We invite you to follow us on Facebook, LinkedIn, X and YouTube to keep up to date on all the latest news, events and innovations to help you take on and solve your toughest challenges.

Want to re-purpose, reuse

or translate content?

Please do, Just link back to the post and drop us a quick email so I can share your work. Thanks!

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.