We’ve had a couple of recent posts about pressure relief valves (PSVs), including Improving Pressure Relief Valve Safety, Reliability and Performance, and Accurately Monitoring Pressure Relief Events. In them was some discussion about conventional PSVs and ones with bellows.

I wanted to learn more, so I found this great explainer video on YouTube. The video, What’s the Difference Between a Conventional and Bellows PSV?, is by Matt Anderson, a Chemical Engineer with a major U.S. refining company.

He shares how a conventional PSV is affected by the backpressure of the header, into which it relieves pressure. This PSV opens based on the differential pressure between the protected vessel and the downstream backpressure in the relief header.

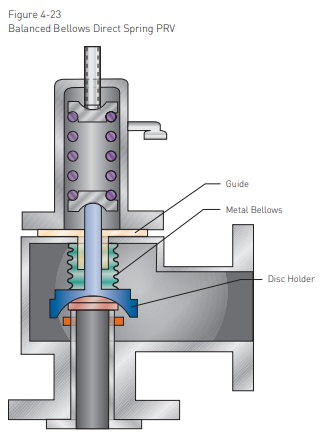

In a balanced bellows PSV, the metal bellows isolate the area above the disc from the superimposed backpressure. Matt references the Pressure Relief Valve Engineering Handbook that defines bellows as:

In a balanced bellows PSV, the metal bellows isolate the area above the disc from the superimposed backpressure. Matt references the Pressure Relief Valve Engineering Handbook that defines bellows as:

…a flexible component of a balanced direct spring valve used to prevent changes in set pressure when the valve is subjected to a superimposed back pressure, or to prevent corrosion between the disc holder and guide.

Emerson’s Marcelo Dultra shared with me that a challenge in the bellows’ design is that they can leak from wear and tear over time. The news, Emerson Reinvents Pressure Relief Valves to Improve Performance and Reduce Emissions, describes Bellows Leak Detection, which:

…addresses the problem of bellows failures, which are challenging to detect and often remain unnoticed for years until removal of the valve for periodic service. Leak detection and repair (LDAR) programs may include PRVs, but their target sources for leakage detection are flanges or valve seats, so bellows ruptures will generate fugitive emissions through the PRV bonnet vent that may not be in the LDAR scope. In addition, PRV installations are often difficult to access and in hazardous locations, making leak detection difficult.

The Bellows Leak Detection solution is a safer and more efficient method for detecting bellows failures and emissions. It consists of a backup piston and a Rosemount™ wireless or wired pressure transmitter. The backup piston can reduce emissions by over 90% in the event of a bellows rupture because it has a much smaller clearance than a standard bonnet vent, and it ensures balanced operation. The pressure transmitter provides instant timestamped notification of bellows failure and emissions volume data in real-time.

And better yet, the bellows can be eliminated.

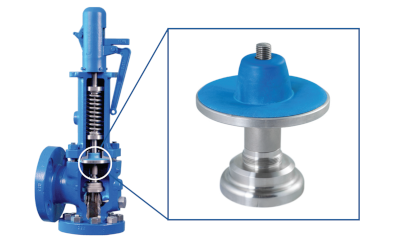

The Crosby Balanced Diaphragm can replace bellows in PRV applications to address these [bellows failure rate between 2% to 6%] and other issues. Its innovative design extends the backpressure limits from 60% to 80% and increases the Kb backpressure correction factor by up to 15%, expanding the application range of spring-loaded PRVs. The Kb factor is used to size PRVs when they are installed in closed systems subject to backpressure. Extending the backpressure limit and increasing the Kb factor often permits the use of smaller valves. In addition, diaphragms are inherently more resilient than bellows for higher backpressures and rapid cycling applications.

Visit the Reinventing Pressure Relief Valves page to request more information and connect with Emerson experts to discuss your applications.