- Make the most of your reliability workforceToday’s plants frequently have limited personnel but still need to find ways to do more work and meet increasing goals and quotas. This dichotomy frequently causes a problem when it comes to asset monitoring, which is traditionally performed by technicians manually inspecting equipment with handheld devices on a regular schedule. In the current environment, plants are faced with a dilemma: do they reduce the manual rounds and commit personnel to other critical tasks with more immediate impact, or do they ensure critical maintenance rounds are completed at the expense of other maintenance needs? Fortunately, today there is another solution. As Emerson’s Drew Mackley and Shane Moser explain in their recent article in InTech, many plants are moving to automated asset management to optimize planning and reduce costs through increased predictive maintenance. However,

“asset management technologies implemented without a plan have the potential to generate problems that complicate maintenance in new ways. To avoid these problems, organizations striving for the best performance must carefully plan system implementation based on a foundation of integration—among technologies and key stakeholders, and with business enterprise systems.”

So much data As plants add more devices to their infrastructure, they gather more and more data. This can be a blessing, but only if that data isn’t siloed by a wide range of software and protocols, and as long as it doesn’t create more manual labor, requiring technicians to sift through mounds of data to identify issues in the plant.Drew and Shane identify how machinery health software can be a critical enabler of better automated monitoring,

AMS Machine Works aggregates data from multiple monitoring technologies to help diagnose machinery health issues.

“To speed ROI, plants are turning to machinery health software packages that can collect data from many types of devices, perform local analysis, and export critical values. These software packages analyze aggregated data from multiple monitoring technologies to make an early diagnosis of developing issues and to help users identify root causes and isolate problems before they become severe. Information is presented intuitively in a single location, so users do not need to search through mountains of data, potentially in a variety of disparate systems.”

Keeping communication open Moreover, machinery health software can be an enabler of better collaboration across the plant. Machinery health software delivers data relevant to a user’s unique role in the plant with intuitive displays showing machine status at a glance. These tools connect users with the other technicians in the organization who can share“established workflows and instant access to manuals, video walkthroughs, knowledge bases, and more to rapidly upskill new and experienced personnel.”

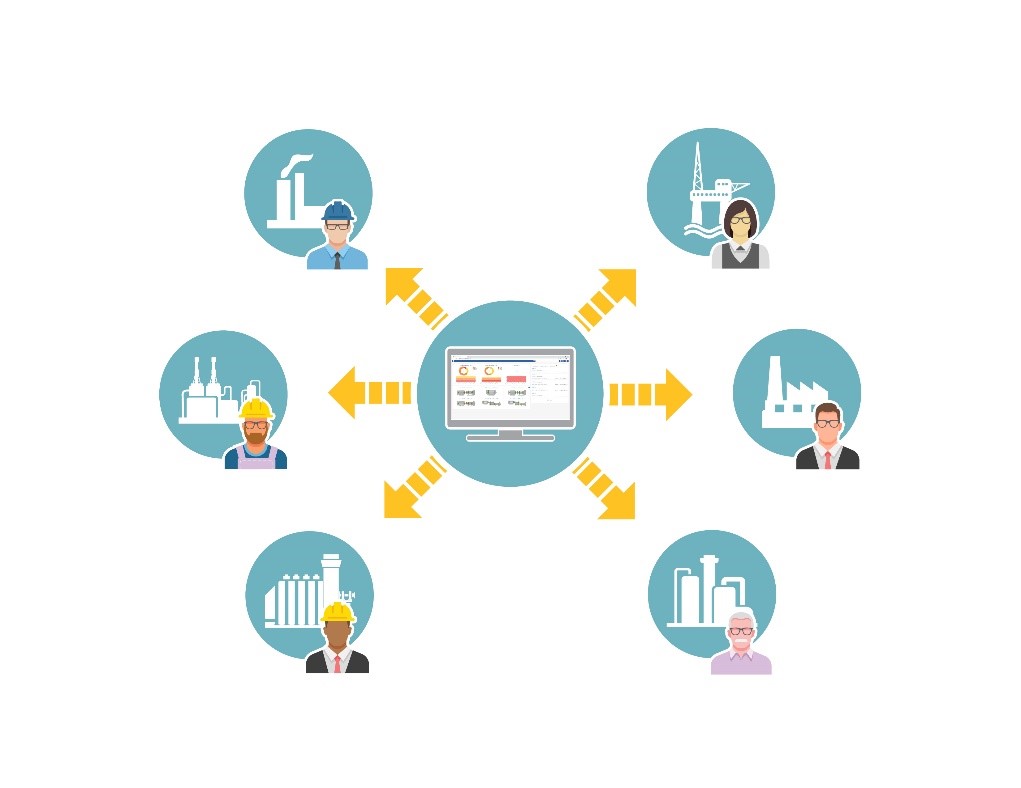

And these same tools can help move critical data up the organization to provide better visibility at the enterprise level for plant-level analytics driven by corporate initiatives. Machinery health platforms can convert machine data into cloud-ready information to be shared across the organization via data repositories, where it can be accessed by enterprise cloud systems for advanced analytics.Today’s tools build a more efficient mobile workforce Emerson’s AMS Machine Works collects data from equipment across the plant and enterprise and presents it in a single location to help personnel of all experience levels more easily monitor, manage, and maintain the equipment in their plant. You can learn more about how moving to 100% automated monitoring can help your mobile workers improve efficiency and ROI by reading the article in its entirety. And while you’re here, I’d love to hear your strategies for making the most of a small workforce on the plant floor!

Machinery health software can help move critical information for better visibility by anyone in the enterprise.

- Industrial Software Enables Performance Gains

The 18th edition of Innovations in Process Automation from the Emerson European team is now available. It’s also available in German, Spanish, French and Italian. This edition highlights some prime examples of Emerson’s industrial software capabilities and explains how these capabilities are helping manufacturers and producers to achieve significant performance gains.

The 18th edition of Innovations in Process Automation from the Emerson European team is now available. It’s also available in German, Spanish, French and Italian. This edition highlights some prime examples of Emerson’s industrial software capabilities and explains how these capabilities are helping manufacturers and producers to achieve significant performance gains.The articles in this edition include:

- Emerson SCADA software simplifies management of photovoltaic power station

- Emerson to help accelerate green hydrogen production

- The next generation of plant data management (Author: John Nita)

- Asset health monitoring and data analysis help maximise plant uptime and efficiency (Author: Alcino Beirão)

- Optimised control and operator performance reduces energy costs and quality variation (Author: Guido Wink)

- Instant access to critical tank data wherever you are located (Author: Catrine Haldorson)

- Emerson solutions are helping life sciences companies get products to market faster (Author: Bob Lenich)

- Cloud-based SCADA solution unlocks maximum value from operations data (Author: Selwyn Hammond)

I’ll recap some points from John’s plant data management article and invite you to register and download the English version or one of the language editions. John is the president of Europe for Emerson Automation Solutions.

He opens the article by explaining how the Plantweb Optics platform supports improved decision-making by collecting, aggregating and analyzing operations data from across an enterprise and delivering alerts and key performance indicators to the right people at the right time.

Better visibility into key operations data is essential for organisations looking to improve efficiency, increase plant and personnel safety, and support predictive maintenance strategies. Digital communications and smart sensing are now providing access to vast amounts of data on everything from process control to asset health, safety and emissions. However, such an abundance of data can prove overwhelming and it can be a challenge to prioritise the most critical information. In addition, data is often isolated in silos across an enterprise – with different departments looking at specific condition or process indicators to set their own priorities – which makes it difficult to identify issues impacting asset availability and operational performance.

The Plantweb Optics platform:

…is an operational performance platform with enterprise-level data management capabilities, which provides a single location to manage, protect and easily integrate operations data with IT tools and cloud applications. This software is transforming data management, helping companies digitally enable their workforce and allowing them to gain unprecedented insight into operational performance at the enterprise level so they can increase efficiency, reduce risk and drive profitability.

It securely unifies:

…structured and unstructured operations data from across a production site or from multiple sites, enabling users to fully leverage this data in their analytics, trending and reporting. By eliminating operational technology (OT) data silos and efficiently aggregating global operations data from manufacturing, process control and IT systems without disruption, users can establish a sound data foundation for their digital initiatives. Beyond the centralising of data, this software also contextualises the data so that it has meaning and is ready for use. What’s more, it can deliver persona-based key performance indicators (KPIs) to enable faster and better-informed decisions that can lead to operational improvements.

Register and download the English edition or one of the other language editions today for more in this article on the methods of plantwide integration, extensibility to AI, machine learning, and industry-based expertise, and the visualizations to enable the information to be actionable and drive performance improvements.

- Podcast: Operational Analytics with Manasi Menon

For decades, manufacturing and production operations created masses of data from sensors, control strategies, diagnostics, procedures and other applications used to safely control the process. Operational analytics have continued to advance to turn this mass of data into actionable information.

Emerson’s Manasi Menon joins me in this 23-minute operational analytics podcast to discuss how organizations are putting these analytics into action to help improve performance in safety, reliability, energy & emissions, and production.

We hope you’ll enjoy this episode and will consider subscribing to the whole Emerson Automation Experts podcast series on your Apple iOS or Google Android mobile device.

Transcript

Jim: Hi, everyone. This is Jim Cahill, and welcome to another Emerson Automation Experts podcast. Today, I’m joined by Manasi Menon. Manasi has a Bachelor of Technology degree in electronics and instrumentation and also an MBA. She’s worked for several automation suppliers and has been with us at Emerson for the past eight years. Manasi currently leads our machine learning and analytics marketing efforts. Welcome, Manasi.

Manasi: Thank you, Jim.

Jim: Well, let’s get started. I gave a little bit of some of your background, but can you give us a little bit more and your path through working with the automation suppliers and Emerson up to your current role with our analytics?

Manasi: Sure, Jim. As you mentioned in the introduction, I am an electronics engineer who’s worked very closely with some of our customers in this process automation industry. There is a lot of interest and there is a lot of talking around analytics today, but our customers have always been using analytics as an opportunity to improve their processes. So, my introduction to analytics was back in the days as a process engineer where I was working for end users who were using conventional advanced process control systems to improve their process, whether it is optimizing their process or monitoring the process. So, right from that time frame, after that, doing my MBA, I ended up in a particular position where I was working as an analyst monitoring the support functions of the organization. So, with that process engineering background and an interest and passion for analytics, I thought this role would be really good where I could contribute to as well as learn from, especially articulating the value add of our analytics in our industry.

Jim: Well, that’s interesting that so many more of our customers are looking at digital transformation and doing something with this wealth of data that they’ve always been collecting. So, I imagine there’s a lot of people on our customers’ side coming into this area of having more responsibilities for analytics. So, I guess with all that, for someone new into the consideration process for additional analytics as part of their automation architecture, what are some ways that they can get started?

Manasi: So, as part of my role, I talk to a lot of customers, some of them who have advanced quite a bit in the stage of deploying analytics in their organization and some of them who are still new. One of the most important things that I have seen works really well when thinking about deploying analytics in their organization is to have a clear goal, a strategy or a clear business goal in mind as to why they want to deploy analytics. Of course, what is also important is once you’ve identified the goal, understand what kind of sponsorship do they have within their organization, to adopt that goal and replicate it. So, that is first step. Then the second step is to identify a clear use case. And it depends on where you are in the organization. It’s very important to collaborate with folks within your organization. And when I say collaborate, what that means is work with plant managers, with the operators, with the reliability engineers because these are the people who are going through those problems, which that analytical solution can resolve.

So, once you talk to them, interview them, you would understand what use case you would like to deploy the analytics to. Then mostly these use cases are very easily replicable or customizable or easily you could deploy it in multiple facets of your organization. So, that’s one consideration to choose that use case. Then when you do that, then you would think about, okay, what does the technology infrastructure that I need to make this possible? Whether it is data, whether it is network or the software application itself that you would use. That’s the typical path that we have seen a successful organization, or a successful customer would do to deploy analytics.

Jim: Can you tell us a little bit more about the different types of analytics that can be applied?

Manasi: So Jim, analytics is extremely broad. Per Clean Energy Smart Manufacturing Institute, there are about over 600 or so analytical vendors out there that offer some types of analytics, whether it is artificial intelligence or machine learning or optical character recognition. So, there are just so much, so much out there. Now, within that, we feel that that space can be divided into two key areas. One is business analytics, focusing on HR, supply chain, finance, and CRM and one is operational analytics, which is I talked about is what Emerson is focusing on, which is the day-to-day operations of the plant. Now, within the operational analytics, there are again two different kinds of analytics depending on the problem that you’re trying to solve. So, if you’re trying to solve the problem of a very well-known asset or a very well-known use case where there is enough subject matter expertise around it, then it’s called principles-driven analytics. If you’re trying to solve a problem that you do not know why it is happening and it may be happening because of the way multiple parameters or multiple things are correlating and interacting with themselves, then we call it data-driven analytics. So, within this operational realm itself, there are two different kinds of analytics.

Now, Emerson has a very, very, very strong background and history of analytics. We’ve had a lot of analytical offerings from 40 years ago, like with AMS Device Manager where we have analytics embedded in our diagnostics devices, to analytics which is embedded within our automation system such as DeltaV, whether it is machinery-specific analytics such as AMS Machinery Manager, or that principles-driven analytics that I talk about, such as Plantweb Insight, which is helping our customers to get started really easy with some of their asset-specific analytics, which is monitoring their health and performance of the asset, to data-driven analytics where you’re trying to solve a problem that you do not know why it’s happening. So, we have Emerson’s KNet that offers advanced analytics techniques in combination with some of these principles-driven analytics to give you a more holistic approach as to why a problem is happening. So, Emerson has a very strong and a variety of offerings to cater to each of these needs. And of course, added to that, which I did not mention and I want to make sure is, is there as part of this whole solution is our AMS Asset Monitor, which is focusing on edge analytics. So, those are the different types of analytics and our different offerings that we have.

Jim: So, what are some examples where other manufacturers and producers are applying analytics and receiving some value from it?

Manasi: So, Emerson’s analytics offering is focusing on what we call operational analytics, which means focusing on the day-to-day operations of the plants itself. So, some of the use cases that we have seen our customers deploying analytics to is in this realm of operational analytics, specifically in the area of process, energy, reliability, and safety. So, let me try and give you an example of each. So, when it comes to process, it is using analytics to monitor your process, whether you’re monitoring the quality of the product and ensuring if it is deviating from a standard spec. So, you’re doing quality control, or you are trying to optimize your process where the analytical application is monitoring the daily operations, change in the operating modes, change in the way the plant is functioning, and recommending a certain set point or recommending a certain way that that plant should operate. So, that’s one area.

The other area where we have seen analytics being applied to is in the case of energy. When I say that, what I mean is in this day and age, every organization, every company has a certain target that they want to meet in terms of energy consumption. So, using analytics to monitor, to calculate, to estimate, and also ensure that the energy consumption of your plant is not deviating from a certain target that you are requiring to meet. So, that’s one example where the analytics application has been deployed by the customer. And the other realm that I talked about is reliability. So, monitoring the health of the asset. And it’s not just monitoring the health of the asset because that’s been done for quite a few years using various pieces of technology, but there is predicting whether an asset is going to go bad, and also using analytics to prescribe as to what should be done when that asset is going bad, so monitoring the health of the asset and monitoring the performance of the asset.

And we’ve actually seen our customers use analytics to start with few and then expand that to a fleet of assets. They tend to do monitoring of the entire fleet in terms of a reliability perspective. And of course, the final is the safety, which is extremely key for any plant in our automation industry. So, ensuring the use of analytics to predict and also to make sure that they can execute a certain procedure in a very safe manner using analytics. So, those are some of the examples where we have seen customers are deploying and getting the value from.

Jim: So, definitely no shortage of opportunities when you look at production, you look at reliability, you look at safety, you look at… What was the one I’m missing?

Manasi: Energy.

Jim: Energy. That’s right. Energy efficiency. So, all kinds of examples. So, if a person picks one of those areas and says this is the part that we’re gonna focus on and try to get some value, some early successes and build from there, what are some important considerations in developing a plan and moving forward?

Manasi: So, let’s say they followed all those steps and they have identified a use case. What they also should do is to have a clear business metric that would warrant the success of that use case. So, have a certain ROI in mind. After that, lay the foundation for the technology. For analytics to work well, the underlying infrastructure of data is extremely important. So, work towards developing that, whether it is data governance or whether it is data storage or whether it is establishing the network architecture to where the use case applies to. So, investing in that. After that, we know you would typically work with a certain vendor to deploy that use case for analytics. And let’s say you’ve done that and you have established a clear business metric or you’ve seen the value add that that analytical solution has provided, the next step that we have seen our customers do is establish a center of excellence, of experts from different parts of the organization who are catering to each of these use cases.

What we have also seen is them partnering with vendors such as us as part of this center of excellence for analytics and then scaling that up to different levels and different…whether they want to move up to a plant level or to multiple plants at an enterprise…or at an enterprise level. So, continue to develop, deploy, find use case, elaborate, and then expand on that. And then finally, also, educate. Each of these…the end users who are using the results of the analytics themselves need to understand how it works and which insights they should tap into. So, continue to circulate that information, which the analytical application is spitting out as in the form of reports, in the form of information among different users and use that in the daily processes.

Jim: Okay. And early on you had mentioned the importance of it being cross-functional, not just one group leading the effort to be successful with it. So, which roles within a company typically get involved in the decisions that need to be made?

Manasi: What we have seen is it is usually the corporate that has an initiative and is taking the ownership in terms of sponsorship and implementing it. When I say corporate, I mean the office of the CIO or the CEO or the COO. But, what we’ve also seen is the individual executives of the plant, whether it is the GM or the VP of the process optimization, or the reliability or the safety or the utility all working together very closely with the vendors themselves and influencing that decision back to the corporate and determining which vendor to go with. So, it’s extremely important to work along with them as well who would ultimately be your champions to get that going within an organization.

Jim: Well, that makes a lot of sense, then bringing people together and getting those various viewpoints to be successful. So, are there any specific examples you can share, of course, without naming names, of companies that have added analytics to one of those areas and seen some quantified results?

Manasi: There is one particular such use case that comes to mind. It is a chemical company, I’m not naming it, but essentially, they followed the same process that I just talked about. They had a corporate initiative to deploy analytics within their organization. What they did was they established a center of excellence which comprised of certain stakeholder from different parts of the organization to come together and brainstorm as to where they would want to apply analytics to. So, this group of body evaluated I think over 50 use cases and then they determined, “Let’s start with the two use cases. And then once we feel that we have achieved that ROI out of it, then we would expand to more.” So, they decided to focus on A, reliability, and B, it was process monitoring. There is a very important reason reliability because it was a repeat concern for them, and it was causing unwanted shutdowns. I think this particular use case caused at least two shutdowns for them, which was unwanted. Process monitoring because the particular scenario that they were dealing with, it was costing them a lot in terms of the product that they were using, so they were wanting to understand how they could use analytics to identify that.

So, these two use cases in mind, this center of excellence, they did have one key person in charge who was working with to evaluate the vendors and everything. They evaluated over 50 vendors and then that 50 went to 12 to 6 and then ultimately, to 1. They then deployed analytics to both of these use cases starting from reliability and then process. And it went really well. When they deployed the analytics solution onto the reliability, they were able to find a problem which their automation system was not able to because the problem was well within the alarm limit that it was intended to be. So, they were immediately able to change their maintenance practices to address that. They then moved on to their process use case and, of course, after that, now they are on the path to scale it up to multiple parts of the organization and multiple plants. So, that was a very good use case where they followed that whole step and now, they are in the process of expanding.

Jim: Yeah. That seems like the way to go about it, identify the possibilities, find the ones maybe with the best chance of success or greatest return opportunity, prove out the value with those and then look to scale and find more opportunity throughout that. Are there things people involved in these types of projects with analytics that they should watch out for and avoid or any kind of guidance you can give?

Manasi: One of the things that I have noticed that people do is they start first with technology and then they think about the use case. So, they would go about, just with an idea in mind that they want to deploy analytics, they would go about starting talking to vendors and looking at the details as to what that application does or does not without really taking a step back and understanding why they should be looking at it in the first place. So, that’s one thing that…setback that I have seen that has happened to them. So, something else that I noticed was getting involved…the timeline that they set for to deploy the use case is so far ahead that they get too involved in that use case itself rather than actually evaluating and giving short iterations and short successes. So, at that time, they end up deploying that use case for more than one year or more than two years without actually having to go back and see why they started this initiative in the first place. So, that’s one thing, starting with the technology itself and worrying about that rather than what they would want to apply to, I think.

Jim: Yeah. And that seems to happen, not specific to analytics but so many things. It’s almost like starting with the possible solution without really a full understanding of the problem, like I have the hammer, now let me go look for some nails or something, instead of understanding the problems, especially what’s the biggest one we can solve that’s not necessarily the hardest one to solve and then build from there.

Manasi: Yeah. That’s a good point. The other couple of points that just came to my mind was another one was working in silo. Let’s say the initiative is starting by one particular site and they’re not really in touch with their corporate, let’s say the IT guys or the technology guys to see what vision do they have. So, working in a silo and not collaboratively. The other key point for analytics to work, people are also important. They are the subject matter experts who are looking at these daily end-to-end results. So, it’s important to continue to invest on them and train them on the analytics application that they are working on. So, not investing there as well is where we have seen where they would decide to go with one application, let it run and then keep on running with that. It is important to have a roadmap. If you are deploying 12 models, out of which these 3 require tuning, retuning, going back and seeing whether it needs to be fitted well with the new sets of data or in a different way that the plant is operating. So, not having that vision in mind, just having one use case and then going with it, that was some of the pitfalls that we’ve seen.

Jim: Well, I think there’s definitely words of wisdom in there for people to look out for things not to do in this to make things be more successful. How can they learn about how our folks at Emerson involved in analytics can help?

Manasi: Emerson has a lot of information out there in our external website. One place that I keep pointing them onto is www.plantweb.com which has a lot of information on how to get in touch with some of our subject matter experts such as our Operational Certainty consultants, our solution architects, our industry experts. They certainly can help with some proven practices such as facilitated workshops or some benchmark processes. They can help you walk you through this process of understanding how to deploy or how to go about finding that use case or deploying analytics in your organization. So, get in touch with your local business representative who can help you get in touch with one of our consultants to help you walk you through that process.

Jim: Yeah, I think what you said there is really important to maybe help on that front end to really scope that process, maybe even bring that cross-functional team together on how to talk in a way that it’s productive and moving forward to identify what are the big opportunities there. Well, Manasi, thank you so much for joining us today. And you enlightened me and hopefully, for our listeners, you’ve enlightened them in to where to get started, things to consider, things maybe to avoid, and how to engage with Emerson to help them improve their business performance in all those different ways. So, thank you so much.

Manasi: Well, thank you Jim, and thank you for providing the opportunity to speak to you.

End of transcript

Visit the IIoT Analytics: Plantweb digital ecosystem section on Emerson.com for more on the array of operational analytics to help you improve overall business performance.

- Podcast: Driving Reliability Digital Transformations

Emerson’s Kendall Beushausen follows up his 5 Questions for Operational Certainty Consultant Kendall Beushausen podcast with this in-depth FIRSTHAND: Operational Certainty in Pod podcast.

Kendall describes how the Internet of Things is all around us in our personal lives and how it is being applied in the manufacturing industries to improve business performance in many areas, especially reliability.

We hope you’ll enjoy this episode and will consider subscribing to the whole FIRSTHAND: Operational Certainty in Pod series on your iOS or Android mobile device.

Transcript

- 5 Questions for Operational Certainty Consultant Kendall Beushausen

Emerson’s Kendall Beushausen joins our continuing podcast series, 5 Questions for an Emerson Expert. As an Operational Certainty consultant, Kendall works with clients to help improve reliability through the application of the latest technologies and improved work processes in process management, maintenance and reliability through the application of artificial intelligence, machine learning and predictive analytics.

In the coming weeks, look for a more in-depth podcast with Kendall on the ways to think about the Industrial Internet of Things and its application in the process industries.

We hope you’ll enjoy this episode and will consider subscribing to the whole FIRSTHAND: Operational Certainty in Pod series on your iOS or Android mobile device.

- Podcast: Digital Transformation for Walkdowns

We continue our FIRSTHAND: Operational Certainty in a Pod podcast series with a conversation with Emerson’s Jerry Chen.

As an Operational Certainty consultant, Jerry works with manufacturers and producers to improve the reliability of their processes. It starts with a complete understanding of the assets used in the production process and keeping these records current as an important component of an effective reliability strategy.

We hope you’ll enjoy this episode and will consider subscribing to the whole FIRSTHAND: Operational Certainty in Pod series on your iOS or Android mobile device.

Transcript

Jim: Hi, everyone, and welcome to another edition of “FIRSTHAND: Operational Certainty in a Pod.” Today, I’m joined by Jerry Chen. You may have caught our “5 Questions for an Emerson Expert” podcast we did together a few months ago. In case not, let me give you his background. Jerry is a Principal Field Engineer on our Operational Certainty Consulting team. They assist manufacturers and producers in developing a sustainable culture of reliability in their operations. Jerry is a mechanical engineer by way of the University of Tennessee, and he has a wide range of industry experience working for Eastman Chemical, Schlumberger, and now, Emerson. Welcome to the podcast, Jerry.

Jerry: Thank you, Jim. Thank you for having me.

Jim: You bet. And today, our discussion is around walkdowns. And I’ve heard the term “walkdown” used in different contexts. From a standpoint of improving reliable performance, what is a walkdown?

Jerry: It’s a great question, Jim. So essentially, a walkdown is to verify the legacy equipment and remedy any gaps in the maintainable equipment asset list. Really, the priority is to identify the existence of this piece of equipment. How can you maintain something that you don’t know exists? So it’s really important to identify the existence of this piece of equipment.

And then it brings another question, which is how credible is that data that’s currently in the ERP [Enterprise Resource Planning] or CMMS [Computerized Maintenance Management System] system? How do we know if we are over or under-maintaining that piece of equipment or maintaining it at all? That’s the purpose of the walkdown, to identify the existence of the piece of the equipment and it’s about finding that baseline and identifying those pieces of equipment.

Jim: Okay, that makes sense. So why are these walkdowns important?

Jerry: walkdowns are foundational to all maintenance programs. You can really, again, only fix what you know that you have. How do you know what you have? By conducting a walkdown. And then it also helps with maintenance work prioritization. You can do a criticality list and identify your most critical assets and focus on those and leverage your resources on the most important assets, so you’re not wasting your time and your resources on less critical items.

And then also, having a CMMS your org maintenance team can count on. That’s one of the important things a walkdown brings is that confidence in you CMMS. And really having that solid foundation helps with doing criticality analysis, helps with building build materials, helps with building accurate PMs to the assets, and really focusing on those critical assets.

Jim: Well, that makes a lot of sense that really getting a good understanding of what all you have and kind of determining priorities and just helping you overall with scheduling and making it more sustainable, all your practices. So what circumstances would call for a walkdown?

Jerry: So I’ve been involved in many, many walkdowns. Really, a lot of our clients just feel that their CMMS is cluttered or has a lot of non-maintainable assets within their system, whether it’s been, you know, a pump’s been decommissioned or part of the plant’s been decommissioned and they haven’t had an opportunity to go through and defragment their CMMS system to remove things like consumable items or ambiguously titled items or things like ladders and non-maintainable items of those nature. Or maybe it’s a greenfield plant and it’s a new plant and they just want to know what is there or if there’s an acquisition and they want to, again, identity what is currently there, what are they getting into.

But yeah, I’m sure we can all think of a handful examples of why it’s important to take inventory of your plant. And the number one big issue that a lot of the plant face are inaccurately populated CMMS systems. Because the last time, maybe, the CMMS was configured was when the whole system was purchased or when it was implemented, but that could have been 10 years ago, and things change over time.

Jim: Yeah, it sounds like there’s a lot of different things that may, from the effort that was done at one point in time, need to be revisited. One of the wonderful things, as we live in this world of advancing technologies is, you know, all these digital tools that come. And a lot of manufacturers and producers are undergoing digital transformations in different areas. How is, from a walkdown standpoint, doing a digital approach different than what’s been traditionally done?

Jerry: Our digital process involves our digital tool, Ordital. It’s, in a nutshell, a photo organization and data extraction tool. Essentially, we use an app to collect the information from the asset, you know, from the name plate or from the equipment, and bring in that data into a loadable format, into your ERP system or CMMS system. And we’re essentially leveraging technology to reduce the amount of information exchange.

As you can imagine, if you’re walking out there with a pen and paper, writing down information, there’s a possibility of human error or transcription error. And then if you introduce someone else, like I hand the paper to you, Jim, and have you enter in that information, it may be hard for you to read my handwriting. We’re trying to minimize that exchange of information by implementing this digital process.

With the picture of the asset and its name plate, we have that information at all times, and we have that information accessible at all times, so we won’t have to go back out to the asset out at the client’s site, because we have a picture of the asset. I guess diving now into what are we doing during the walkdown with the app? So we’re using the app to collect data on the asset while, at the same time, organizing that data in real time: categorizing the photo as a piece of equipment or categorizing the photo as a name plate for that piece of equipment, or identifying tag photos.

In other processes or in the past, traditionally, people have used pen and paper or a steno pad and that is prone to errors. Or, you know, some of our competition, they’ve been using tablets. But a majority of them essentially are using it as a digital pen and paper method, so that typographical error is still there. Maybe handwriting isn’t an issue anymore since it’s digital, but, again, typing it in possibly introduce error.

Our process involves taking that physical photo of the data so there aren’t any discrepancies, there isn’t any bias, and we have the photo as the source document and we can always refer back to it if we need to, so reducing that possibility of human error.

And then after the walkdown is complete, we’ll provide the pictures of the equipment, the name plates, the tags, vendor photos and we provide that to the client. And what we really do at the end is we provide the most critical attribute data and transcribe it so they can populate their CMMS so they can be more effective with their maintenance and identify those gaps in their equipment or supply chain and identify obsolescence if… So you have a pump and that pump manufacturer has gone out of business. Well, it’s time to start phasing in a new manufacturer, and that way, you can get ahead of that obsolescence.

Yeah, ideally, using this digital method is not only saving time and money, but most importantly, we’ve increased the accuracy with the digital method. And our belief here at Operational Certainty is that accurate data drives effective maintenance.

Jim: Well, yeah. What you’ve just described between putting something on a pen and paper and especially if you’re handing it to me, who knows what you’re gonna get in that database there. To capture it electronically, to put it into that database, make it searchable, all the other things we get from our digital world, that just seems like such a better way to be able to do that. So can you share any generic examples of walkdowns you’ve participated in and some of the results that were achieved?

Jerry: Recently, I was on a project with three of my teammates and we recently went offshore. The team was comprised of two baby boomers, a gen-xer, and myself, a millennial. I had used the app before, but this was the first time for them to use the tool. And wow, did these buys pick it up fast. They were capturing the assets three times as fast as opposed to using a pen and paper. They could see the time savings immediately. And with those time savings, we were able to re-allocate that time for additional hierarchy development, additional asset collection, and additional time to QC [quality control] the data. So we were delivering a topnotch product to the client.

Really, the client was very surprised at the speed that we completed the walkdown, but they were more thrilled with the outstanding data that we delivered and the photos we delivered. So overall, we delivered the asset data with photos and additional level of confidence that they hadn’t seen before from our competition.

Jim: Well, that sounds like a real digital transformation to the whole walkdown process. Great. Can you give us a glimpse of what the future looks like for walkdowns?

Jerry: We live in this world of technology and finding ways to implement it. And I, myself, am an early adopter of technology. I love finding ways to implement technology. Sometimes, it may slow down the process in the beginning, but overall, it’s going to speed it up. The future of walkdowns, foundationally, maintenance hasn’t changed. Things are going to wear and break. Hopefully, we can fix them before they do.

Right now, we’re working on implementing augmented reality or mixed reality and virtual reality into the walkdown process, essentially, creating a 3D version of your plant so that you can get a Google Street View of your plant. That way, you’re not spending additional time in hazardous environments or danger if they don’t need to be in danger.

We’ve shown it to a client and they just get awesome ideas from using the private Google Street View, per se, of their plant. And there’s a huge possibility for applications of this new process.

Jim: Well, Jerry, I think you’ve given that Google Street View analogy, I think, paints a great picture, you know. You imagine you’re in your plants and looking around and being able to see that from your desktop and really pinpoint things, that really seems like an exciting future of what is coming for walkdowns and what we’re already seeing here today. Really appreciate you sharing and painting such a great picture of how walkdowns are going through this digital transformation. So thank you so much for joining us today, Jerry.

Jerry: Thank you very much, Jim.

End of transcript

Visit the Operational Certainty section on Emerson.com for more on the methodologies to apply technologies to digitally transform your manufacturing and production operations. You can also connect and interact with other Industrial Internet of Things (IIoT) and digital transformation experts in the IIoT & Digital Transformation group in the Emerson Exchange 365 community and/or at the September 23-27 Emerson Exchange conference in Nashville.

- Podcast: Driving Operational Improvements in the Energy Industries

Emerson’s Sudhir Jain joins us in this FIRSTHAND Operational Certainty in a Pod podcast as a follow up to our earlier 5 Questions for an Emerson Expert podcast with Sudhir.

Emerson’s Sudhir Jain joins us in this FIRSTHAND Operational Certainty in a Pod podcast as a follow up to our earlier 5 Questions for an Emerson Expert podcast with Sudhir.As an Operational Certainty consultant, he shares some of the oil & gas applications for operational improvements and describes how he works with clients to improve overall performance and sustain it over time.

We hope you’ll enjoy this episode and will consider subscribing to the whole FIRSTHAND: Operational Certainty in Pod series on your iOS or Android mobile device.

Transcript

Jim: Hi, this is Jim Cahill with another edition of “FIRSTHAND: Operational Certainty in a Pod.” Today I’m joined by Sudhir Jain. You may have heard our earlier “5 Questions for an Emerson Expert” podcast with Sudhir. Today we’ll explore how he works with clients to improve business performance in their production and manufacturing operations. But first, some background. Sudhir is a process automation and digital transformation specialist on our Operational Certainty Consulting team. And he works with clients in the oil and gas refining, petrochemicals and chemicals and life science industries. He has over 35 years of process automation experience and has been with Emerson for over 20 years. He has a Bachelor of Engineering degree in instrumentation and control engineering and an MBA. Welcome, Sudhir.

Sudhir: Thank you, Jim.

Jim: All right. Well, let’s start out, how do you typically first get engaged with our customers in solving their operational challenges?

Sudhir: We do go to various trade shows. And, you know, we have our application suites on the web, as well as we have the field salesforce, like our Impact Partners and our account directors. So, whenever they hear about the applications or solutions which we can provide at operational certainty consulting, they basically contact us to meet with the customer or to talk to the customer.

Jim: So, once you’ve gone through the introductions, how do the projects typically begin?

Sudhir: Well, once our salesforce finds the opportunity for the applications which we do, they connect us with the customer. And we either meet on the WebEx meeting or face to face, and during face-to-face or any other discussions, we find out what are the customer objectives for the application he’s looking for, because most of the time in oil and gas upstream as well as downstream, which is my focus right now, we see that there is a little difference of the process workflow which they have. And that’s where we find out what are their objectives, can we meet their objectives, and if we can, then address them during the meeting to engage him more deeply.

Jim: What are some of these applications that you help them with?

Sudhir: Today, the upstream applications are common, whether it’s conventional or unconventional. But in North America our focus is more on unconventionals, because that’s what is more engaging nowadays. Most of the unconventional fields, since they are fracking, we find that they have to use an artificial lift whichever way they want to. So, we provide the solution for artificial lift optimization, for example, gas lift optimization. In our applications, we have some of the good experience in dynamic lift optimization which can use either gas or the ESPs [electric submersible pumps] or beam pumps, whatever customer is using.

Jim: Okay. And when you work with them, I guess a lot of times you’re bringing in some new technologies that might not be familiar with them. How do you familiarize them with new technologies you might be introducing in a solution?

Sudhir: Yeah. Well, most of the time, customer expect us to talk about systems and control systems. But the applications which we are talking are more of software solutions, and these are not product. These are customized to the customer requirement but have a standard implementation process. So, we have created some of the simulated demos. What we find is after the initial introduction on the PowerPoints to tell them how this technology works, how the communication or data flow is there, we like to show them the demo so that they can see one-to-one correspondence to their application, how it will be implemented, and how the visualization or dashboard looks like, how it can help their operators and production engineers.

Jim: So, once, I guess, they see that and have a good feeling for how it looks like, how do these projects typically kick off?

Sudhir: Well, once the customer sees that this application is going to help them or increase some of their production outputs, they contact us based on what they have in mind, which means sometimes they ask us to give a proof of concept or a pilot. And if we have already done the pilots and we give that reference, then they basically ask us to give a proposal. And once we get an order, we have a survey of the facility. And at the same time, we have an implementation plan and the schedule in which we will do the job.

Jim: Okay. So, once you’re there, you get the project, you start the project. As you get towards the backend, how is success measured for a project?

Sudhir: In fact, what we do is in our proposal, we always include that we are asking for the feedback or the data after the project is successfully implemented. Mostly in these projects, the responsibilities are divided. And those are also up front stated in the proposal, and they have to agree upon. So, once the project is complete, since we have worked together, actually relationship is really good. And we do get the data time to time during our implementation process. But finally, once they operate for, say, a month or two, they send us the data and we calculate the ROI. In fact, before even we calculate the ROI, they calculate the ROI and share with us.

Jim: Yeah. And that definitely they want to promote the ROI success they have with their own management teams and everything else…

Sudhir: Absolutely. They want to sell to their management that what a good job they have done and increased their output by 4% to 14% depending on where we are operating.

Jim: That’s great. Once those initial results are achieved, how do they sustain them over time?

Sudhir: We always ask them every quarterly data, reason being, it’s not very difficult to analyze. Now, these are very simple processes, because the way it is designed and the way we have our dashboards there, but every three months, we also want to see there’s a consistency in the operational efficiencies, whether they have improved, if they have gone down, did they shut down somewhere else or something else is happening. So, they always give us the regular feedback, at least first year, just to make sure that the process workflow is working, all the operators are happy with it, so that we can do more with them.

Jim: Without naming customer names or anything, can you share some generic examples of some successful projects?

Sudhir: Well, recently, we finished a project on dynamic lift optimization with one of the major IOC [International Oil Company]. And as I said, they shared the results. They were pretty happy the way it was going. And this was in a conventional field, in fact, and now they’re big time in unconventional, and they told us that, you know, we would like to get this done in the unconventional. So, that’s an opportunity which came just because we did the project. Apart from that, our group does a lot of reliability-based solutions. And we do some downstream, you know, applications, and those are also discussed, I guess. Like we say, once you get trusted, they try to see what else we can do in their plans.

Jim: Yeah. I guess if you get good solid ROI on one project, then you start looking for other opportunities there to apply that more broadly.

Sudhir: That is correct.

Jim: And let’s wrap up with, you know, we have our big Emerson Exchange conference, both here in the U.S. in the fall, I guess, end of September this year in Nashville, and also for Europe, which will be in Milan, Italy next spring. So, how does that work or how do you engage with our customers to be able to have them share some of their successes with other customers at these Emerson Exchange events?

Sudhir: I think the Emerson Exchange is pretty popular with our customers. Most of the time, they already participate, so they understand the importance of it. And once we see the project is successful, we actually request them to participate, present a paper. We share the data with them, and if they need help, we also support to provide data for their presentations, so they can share. And we have seen that in the last seven years, a number of customers presented the results, which is more effective than us presenting the results.

Jim: Yeah, and that’s something that, you know, other customers like to hear from other customers, their successes, not necessarily from Emerson people telling some of these successes. And I guess the really good deal in all that, too, if they’re willing to do that, then their conference fees get waived for doing that, so…

Sudhir: That’s how we encourage them.

Jim: Yes. That’s a great deal there. Well, Sudhir, thank you so much for joining us today and sharing some of your insights with these projects.

Sudhir: Thanks, Jim.

End of Transcript

You can connect and interact with other operational improvement experts in the Services group in the Emerson Exchange 365 community.

- 5 Questions for Operational Certainty Consultant Jerry Chen

Emerson’s Jerry Chen joins our continuing podcast series, 5 Questions for an Emerson Expert. As an Operational Certainty Consultant, Jerry works with clients to help build a reliability culture for their maintenance professionals. He works with them to implement the technologies and to establish the work practices required for more reliable and streamlined operations.

In the coming weeks, look for a more in-depth podcast with Jerry on the walk down process to identifying and improving reliability.

We hope you’ll enjoy this episode and will consider subscribing to the whole FIRSTHAND: Operational Certainty in Pod series on your iOS or Android mobile device.

Transcript

- Podcast: Driving Reliability Improvement Gains

Emerson’s Dave Buttner joins us in this FIRSTHAND Operational Certainty in a Pod podcast as a follow up to our earlier 5 Questions for an Emerson Expert podcast with Dave.

In this podcast, he shares some of the drivers, challenges, and methods of sustaining reliability improvements for better business performance.

We hope you’ll enjoy this episode and will consider subscribing to the whole FIRSTHAND: Operational Certainty in Pod series on your iOS or Android mobile device.

Transcript

Jim: Hi, this is Jim Cahill and welcome to another edition of FIRSTHAND Operational Certainty in a Pod. Today I’m joined by Dave Buttner who’s a Business Development Director for Emerson’s Operational Certainty Consulting practice. And Dave has a project management professional and certified maintenance and reliability professional certifications. So Dave, what are common concerns you hear that drive manufacturers to pursue help with reliability improvement initiatives?

Dave: Jim, typically, in the economic state that we’re in right now, where, you know, we’ve seen a pretty extensive growth for many months, if not many quarters, a lot of our customers are kind of tapped out in terms of their capacity. So, they’re pretty much…they can pretty much sell anything they can make and so that it creates a situation where it’s pretty simple for them to see that if they can make more with the same capacity, a level of capital equipment, then they can make more money. I mean, I don’t think that’s rocket science there. That is something that really helps drive a great deal of demand for Emerson’s products and services. And also, we think, you know, it helps drive demand towards our services because we can help our clients make good decisions about criticality, where they should be deploying their technology investments or condition monitoring and their production optimization technology investments.

So, really, the hot economy I think helps drive it and it doesn’t always have to be in other different cycles, obviously to the economy. And sometimes in a slower economy, you know, a lot of manufacturers are trying to produce on fewer shifts. So, they’re trying to kind of control their variable costs, which means that reliability is, once again, very important because instead of running 7 by 24, every day of the week, every hour of the day, they may be running maybe just 2 shifts a day, 5 days a week. And that means that they need to get a certain production level of it. So, reliability is always important, I think that the taste for reliability products and services, you know, does have an epic flow to it.

Jim: Yeah, that’s interesting that in the economic conditions we’re in now there’s lots of levers that people can pull to improve performance and just given the current state, reliability sounds like it’s one of those biggest levers.

Dave: Once again, related to the tight economy, I think we all know that the labor market is, fortunately, you know, I think for all of us very, very hot. But that also means that a lot of companies aren’t staff to get better, they can’t go out and hire the staff to go from a certain production level to a better performance result. And so, they’re more willing to look at outsiders to help them get there. And I think that’s also been something that we’ve been seeing, driving a lot of our business. We’re the helping hands that…they have that capability internally, but those people are tired of running the business.

Jim: Well, that makes a lot of sense. So, how does reliability enhancement help businesses reach their business objectives?

Dave: The math is pretty simple. If you have a fixed capital investment and you can produce more oil, tablets, whatever it is you make, with the same capital investment, it’s gonna increase your return on assets and that helps drive shareholder value for our customers. So, the math is pretty simple and it makes it kind of an easy sale at the conceptual level, but what I think a lot of times our customers don’t always appreciate is the complexity that it takes to simply get another 1% or 2% of equipment availability, you know, out of their plants. That’s…logically, it’s easy. Tactically, it’s…can be challenging. And that’s one of the things that we help our clients sort out is what should be the sequence of events that help drive them towards a higher level of performance.

Jim: There’s a lot of things that it sounds like it’s an easy thing, but when you really try to get in and do it, then that’s where the challenge opens up. So, if a manufacturer or a producer decides to move forward and work with the Emerson reliability consulting team, what are common preparation steps they would take to prepare for the engagement?

Dave: Generally speaking, they have to have good performance measurements. So, if they’re hiring us to help them improve their line efficiencies, if it’s consumer-packaged goods, operation, or just their overall throughput, if we’re talking about a larger, you know, perhaps an oil refinery or petrochem facility, they need another…their measurables, they need to know how they perform now. Ideally, they have some sense of what the root cause issues are in terms of what’s affecting their performance, their reliability performance. So, if they don’t have…chances are they’re not gonna be talking to us unless they have those measures. But if they’re gonna engage us, they need to have more detailed measurements in place so that we can establish a baseline and agree upon what the targets are. Because it’s not just about deploying the tools and the technology.

It’s about driving towards a better performance level, which means that we have to have a baseline measurement and we have to have a committed to target improvement. And then it’s our job to help the customer get there. It’s not our job to get there, they’re hiring us to help them. So, besides measurement, there’s also—they have to figure out what they’re willing to commit in terms of the resources internally to help drive the results. Because once again, they’re not hiring us to run their plant better, we’re there to help them, provide them with the tools and the techniques to do it.

Jim: You really need the measurements to start with baseline to know and then that’s all part of the business case where you’re at, where you’re trying to get to. How does engagement typically kickoff?

Dave: It’s very common for us to open up with establishing what we might call strategies, or customer might call policies. We sometimes will call them project rules, that is… Okay, so we’re going to improve the maintenance strategies or the predictive and the preventive maintenance procedures that a client deploys to maintain their equipment. We have to agree with them, like, in what should be their standards for what makes a good preventive maintenance procedure. What does a good job plan look like? So, it’s really establishing standards at the outset so that we all agree, and we help kind of facilitate that. We don’t come in and we tell them what to do, we help facilitate them towards kind of a best practices-oriented outcome. So, that establishes the foundation for what it is we’re gonna do next. And beyond standard project management, procedures and tools that we might put in place for a project, that’s really kind of at the heart of how we kick off a project with a client.

Jim: Yeah, and that sounds like important, especially if they have cross-functional team working at that to gain alignment there on the front end as those standards are everyone agreeing to them.

Dave: Yeah, I mean, the flip side of that is if you don’t do establish the standards, what are the project rules, then you encounter what we refer to as regret work, then we’ve started down a path. And then somebody decides, some stakeholder that maybe wasn’t identified early on by the client says, “No, that’s not the way we wanna do it.” So, it’s all about establishing a foundation.

Jim: Yeah, makes perfect sense. So, Dave, what are typical timelines in executing these projects?

Dave: Yeah, kind of a hot area for us is what we call bad actor processing unit, PM [preventative maintenance] and PdM [predictive maintenance] optimization. That is whatever they’re going to do proactively on a certain processing unit that doesn’t run very well. We can help them improve that and also provides an opportunity to deploy some sensing technologies that they may make it then a better result from the proactive maintenance standpoint. We can design that outcome that is, “You’re currently doing your maintenance this way. And then we’ve got a new approach that we’ve all agreed upon and all the details and it’s all loaded onto your system and all scheduled.” And typically, in three to four months, depending upon the size of the processing unit, the number of actual assets involved in it. But what we really find is, is that you wanna spend at least another few months at the back end of that project, where we help them from a kind of a coaching standpoint, to help drive towards a better result.

Because one of the things we’ve learned is you can put tools and technology in place, you can put Emerson’s great vibration monitoring tools in place. But if people don’t use the tools and act timely to repair something that is getting ready to break, then you don’t get the result that you’re striving for. So, just building the better platform can be done rather quickly but building the change in helping to start drive some cultural change can take, you know, weeks, if not months afterwards.

Jim: Yeah, that I can see, you know, it’s…you’re asking them not just employing technology but to use it and change the work practices and everything and that takes, I think, some reinforcement over time. So, having that part and thinking about that as part of the project to get it to stick, because you’re right, the last thing you wanna do is come in, put all this stuff, have nobody use it and then really not impact change that way.

Dave: Yeah, one of my funnier quips that I tried to use to make a more serious point with clients goes like this, “If a vibration alarm goes off in the control room, and no one pays attention to it, it didn’t make a sound.”

Jim: I like that, I like that a lot. So, given that, what type of training and ongoing support is typically provided?

Dave: Being part of Emerson, you know, one of the…I think one of the real differentiators we have, particularly in our North American business, is we have a great Impact Partner or Local Business Partner, as we used to call them. Our Impact Partner network and those Impact Partners provide a lot of great engineering skills and services at the local level to our customers. And so, they’re around to help them if they didn’t historically deploy much vibration, or much fluid analysis, or whatever it is that we’re helping them improve in terms of their maintenance practices. The Impact Partner has resources that can help provide some continuous technical and tactical training to our customers. In terms of what, you know, our consulting group may provide an ongoing services, I’d like to keep it really simple and it can be as simple as on a bi-weekly basis. We get together and we look at what our performance metrics had been for the last two-week period as it relates to our baseline goal, as it relates to our targeted goal.

So, to give you a specific example, let’s just say that a customer is currently running a certain cat cracker unit at a refinery at 85% availability, they wanna target 92% in the near term, they probably have a higher goal than that. We’re gonna establish some kind of a timeline with them for driving towards that improvement. So, we wanna take measurements on a systematic basis, you know, over a period of weeks and months to help drive towards that. And so, if we did at alarms, they have to…it helps the client make sure that they’re telling the people in the control room to pay attention to them.

Jim: I like what you said there about that blend of some of that reliability expertise that the consulting team brings, plus the expertise of the Impact Partner or people local to the area to be able to work with them and on an ongoing basis after that to really sustain the, you know, the value that gets created from doing that. What are some of the results your team has seen in executing these projects?

Dave: Well, it’s just we do operate in a wide range of industries, at least in our particular group. Emerson has a lot of industry verticals that are focused on refining, food and beverage, power gen, a lot of significant industry verticals. We’re a little bit more industry agnostic, I guess, I would use the term. So, it’s a wide range of responses I could give you here. I think we did talk a little bit about in refining, you know, the driving towards a 5% to 7% availability improvement, but like in consumer-packaged goods where a lot of times you’ve got…a lot of your production is driven down to a specific line level, you know, where we run a certain product on a certain line.

We typically wanna target at least an initial improvement goal of 3% to 5% line efficiency. And one of the things I’ve learned, because I have personally dealt a lot in that realm, is that each 1% is normally worth around $15,000 a year. So, we’re not talking a lot of money, but when you’re talking about a lot of these plants have 10 lines and they can derive 3% to 5% in the near-term improvement, it does add up and it normally generates a significant return on investment for the client.

Jim: And it’s reoccurring savings if they can maintain the improvements that they’ve seen over time, so, compounds year after year, those savings. Okay, so let’s wind this down, I got one final question for you, Dave. And that’s, where would you recommend people go to learn more about Emerson’s approach to reliability enhancement?

Dave: Well, you can always just send a web search Emerson Automation Solutions, a lot of our products and services and you’ll also find our web pages around operational certainty consulting. You can talk to our Impact Partner channel network, you know, within the North American space. You can also just send me an email at [email protected].

Jim: Well Dave, thank you so much for joining us today.

Dave: I appreciate your time, Jim. Appreciate the audience’s time.

End of transcript

- 5 Questions for Operational Certainty Consultant Dave Buttner

Emerson’s Dave Buttner joins our continuing podcast series, 5 Questions for an Emerson Expert. Dave works with manufacturers and producers as part of the Operational Certainty Consulting team to identify opportunities for performance improvements in safety, reliability, production, and energy & emissions.

We’ll have a more in-depth podcast in the coming weeks with Dave describing the process of how the Operational Certainty consultants work with clients and some results they’ve seen.

We hope you’ll enjoy this episode and will consider subscribing to the whole FIRSTHAND: Operational Certainty in Pod series on your iOS or Android mobile device.

Transcript