At the Emerson Exchange 2025 Conference, Emerson’s Marcelo Carugo and Doug Cooper joined Hydrocarbon Processing Magazine podcast host Lee Nichols to discuss advanced digital technologies to combat corrosion.

Permasense

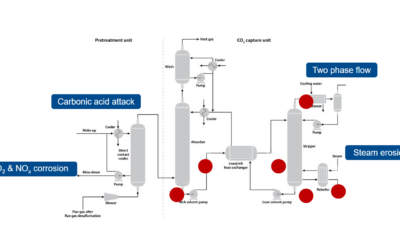

Surveillance de la corrosion et de l’érosion dans les applications de capture du carbone

Dans une présentation à la conférence sur la santé, la sécurité et l’environnement 4C, intitulée La corrosion et l’érosion sont responsables de 56 % des pertes dans les tuyauteries. Surmonter ces défis tout en augmentant la capture du carbone., Justin Vasquez d’Emerson a décrit les défis et les solutions pour traiter ces conditions.

Korrosions- und Erosionsüberwachung in Anwendungen zur Kohlenstoffabscheidung

In einem Vortrag auf der 4C Health, Safety & Environmental Conference mit dem Titel “Korrosion und Erosion betreffen 56 % der Verluste bei Rohrleitungen. Diese Herausforderungen überwinden und gleichzeitig die Kohlenstoffabscheidung steigern.” beschreibt Emersons Justin Vasquez die Herausforderungen und Lösungen zur Bewältigung dieser Bedingungen.

Monitorización de la corrosión y erosión en aplicaciones de captura de carbono

En una presentación en la Conferencia de Salud, Seguridad y Medio Ambiente 4C, titulada “La corrosión y la erosión están relacionadas con el 56% de las pérdidas en tuberías. Superando estos desafíos mientras se incrementa la captura de carbono.”, Justin Vasquez de Emerson describió los desafíos y las soluciones para abordar estas condiciones.

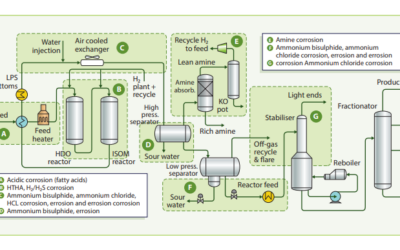

Managing Biofuel Processing Corrosion Risks

In a Decarbonisation Technology article, Managing corrosion risk in SAF and renewable diesel processes, Emerson’s William Fazackerley describes how non-intrusive real-time corrosion monitoring provides early warning of corrosion issues to enable early mitigation actions.

Navigating Corrosion Hotspots in Amine Units: A Guide for Refineries and Gas Processing Plants

Amine units are critical components in refineries and gas processing plants, removing acidic contaminants like H2S and CO2 from process streams. However, these units are particularly vulnerable to corrosion, which can lead to costly shutdowns and safety risks. Let's...

How to Monitor the Effects of Sand Erosion at Oil and Gas Production Sites

When it’s time to repaint the ironwork of a bridge or building, what’s the best way to strip away old paint and rust? Sandblasting is usually the first choice because it is very effective at eroding surface crud and getting down to clean metal, but if it continues too...

Non-Intrusive Flare Header Technologies

At the 2024 4C Health, Safety & Environmental Conference, 4C Marketplace’s Steve Probst and Emerson’s Marcio Donnangelo presented Flare Headers Non-Intrusive Technologies.

Managing Equipment Damage Caused by Corrosive Feedstocks Encountered with Biofuel Production (Part 2)

When we talk about renewable fuels to the general public, many might imagine cars running on gasoline made from wildflowers and meadow grass. However, those who work in the industry recognize that the fats and oils used to make renewable diesel can be just about...

Managing Equipment Damage Caused by Corrosive Feedstocks Encountered with Biofuel Production

When we talk about renewable fuels to the general public, many might imagine cars running on gasoline made from wildflowers and meadow grass. Those who work in the industry recognize that the fats and oils used to make renewable diesel can just about be anything but...

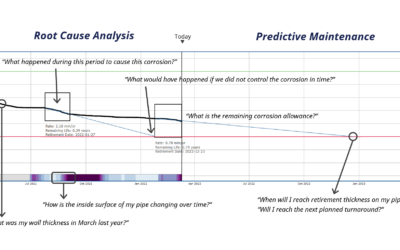

Greater Reliability with Non-Intrusive Wireless Corrosion Monitoring

At the 2024 4C Health, Safety & Environmental Conference, Emerson’s Justin Vasquez shared a presentation, Enhancing Safety, Profitability, and Sustainability through Wireless Corrosion Monitoring: A Focus on Reliability with Non-Intrusive Monitoring Devices.

Solving Corrosion Problems by Treating Metal Deterioration as a Process Variable

Imagine that you’re called into your plant to solve a recurring problem. The operator states: “We’ve had to replace this valve three times this year due to failures from over pressure.” Your first question is pretty obvious: “How high is the pressure?” The operator...

Keep Up to Date With the Latest News and Updates

Follow Us

We invite you to follow us on Facebook, LinkedIn, Twitter and YouTube to stay up to date on the latest news, events and innovations that will help you face and solve your toughest challenges.

Do you want to reuse or translate content?

Just post a link to the entry and send us a quick note so we can share your work. Thank you very much.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.