Tools and methodologies to improve plant reliability have existed for many years. Examples include criticality analysis, reliability-centered maintenance analysis (RCMA), failure modes, effects, and diagnostic analysis (FMEDA) and root cause failure analysis (RCFA) to...

plant equipment reliability

Detecting and Analyzing Mass Speed, Force, and Impact

When performing vibration measurements during route-based maintenance activities, different vibration measurements uncover different issues with plant machinery. In this 4:20 YouTube video, PeakVue Analysis, Emerson's Mark Granger demonstrates some of these...

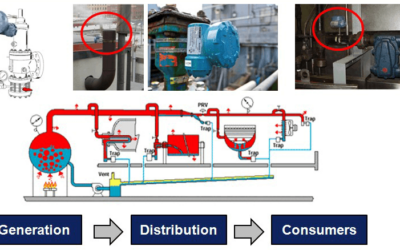

Optimizing Steam Usage in Oil and Gas Processing Complexes

Utility management is a large part of the oil and gas industry and boiler management and steam balancing is often an overlooked factor for upstream and downstream processing. Steam optimization helps to reduce boiler loads, streamlines process efficiency and enables...

Industrial Energy Team Peels Reliability like Onion!

Having reliable process manufacturing operations begins with reliable components and reliable control strategies to handle changing conditions. Emerson's Jennifer Sandstrom, a senior industrial energy consultant, highlights the role of consultants in unpeeling the...

Keep Up to Date With the Latest News and Updates

Follow Us

We invite you to follow us on Facebook, LinkedIn, Twitter and YouTube to stay up to date on the latest news, events and innovations that will help you face and solve your toughest challenges.

Do you want to reuse or translate content?

Just post a link to the entry and send us a quick note so we can share your work. Thank you very much.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.