Process manufacturers continue to seek ways to improve their energy efficiency, due to the high cost of energy. Corrosion and solids deposition in boilers, condensers, and steam turbines reduce the efficiency of this equipment and increase energy usage. This can also lead to unscheduled downtime if the conditions persist long enough to cause equipment failure.

One important way to minimize corrosion and the formation of solid particles is to have ongoing, accurate and reliable pH control in the boiler water, boiler feedwater and steam condensate, and main steam (carryover.)

The challenge is that these applications are often very low in conductivity. This is a challenge for continuous pH measurement due to the unavoidable formation of liquid junction potentials in the reference sensor. These cause offsets and instability in the pH measurement.

Emerson’s Brian LaBelle, a power industry manager for Rosemount Analytical liquid analytical devices, explained these junction potentials are caused by spontaneous migration of ions from more concentrated to more dilute solution within a pH sensor electrode. What happens is a charge separation occurs among the various ions present. (At the word “ion”, my mind raced back to those repressed memories of college chemistry lectures…)

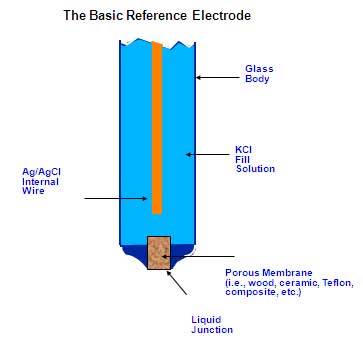

Sometimes a severe junction potential occurs when there is an imbalance of negatively and positively charged ions across the liquid junction found in the basic reference electrode. The lower the porosity of the junction, the greater is the charge separation across this junction.

Sounds like we’ve gone a long way from the original problem of keep the equipment from corroding and being gummed up with solid particles.

Brian brought me to the solution by explaining that the technology team came up with the solution of replacing the diffusion junction with an open capillary (that’s a hole for most of us.) Actually, this is not new or innovative, but what is innovative is that precise, laser drilling on a micro-scale of tens of microns is far more precise than what can be achieved with a twisting, mechanical bit. To minimize the junction potentials and provide more accurate measurement, the optimum capillary is laser-drilled at 25 microns in diameter. This capillary is also tapered outward to the outlet filter to help avoid clogging.

As we depart the micro world of ions and laser holes and return to our world of boilers, condensers, and steam turbines, the pH measurement with the Rosemount Analytical 3200HP pH sensor provides more accurate and reliable continuous measurement to ward off corrosion and solids formation. This means more reliable, efficient operations for this energy-consuming equipment.