Last week at the ISA Expo in Houston, I sat in on a great session featuring Emerson’s Ed Bailey, as well as folks from Siemens, Ametek and a private consultant with years of experience with Dow Corning. The session was entitled, Energy Management Issues for Process Optimization, and it had the following description:

Subjects open for discussion in this session include nearly anything relevant to this topic, not just process control and instrumentation. Expect discussions regarding process maintenance, process modifications, maybe whole new processes that were less cost effective under the old energy cost structure but now are more cost effective.

Ed leads the technology development efforts for the Rosemount Analytical Gas measurement products. He kicked off the panel discussion showing the forecasted growth of energy production. From an ExxonMobil outlook study, most of the world’s growing energy needs will continue to be met by the combustion of oil, gas, and coal.

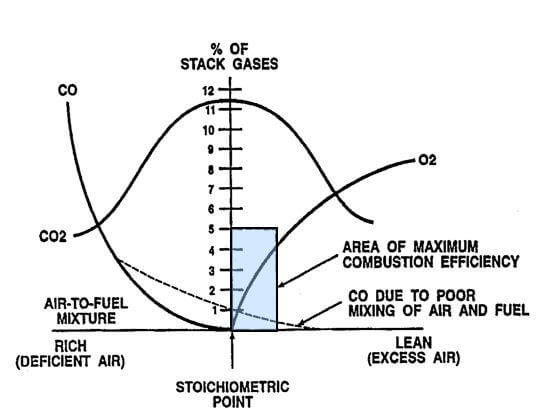

To help manage the carbon emissions, to deal with the increases in fuel costs over their historical averages, and to operate in an environment with increasing governmental regulations, process manufacturers have an ever-increasing need for improved combustion flue gas analysis. The best way to minimize carbon dioxide (CO2) emissions is to operate existing combustion processes at their maximum efficiency.

Ed described some of the existing industry practices like averaging the output of a few analyzers as not providing enough insight to diagnose and optimize the burners. Burner differences and stratification are normal conditions that this averaging strategy does not well address. Instead, Ed recommended a mix of oxygen (O2) and carbon monoxide (CO) measurements be used combined with neural network strategies that enable more complex models to be created to maximize efficiency versus the load/fuel variations–and to minimize mono-nitrogen oxide compounds (NOx). The key point is that more discrete measurement points, which in turn feed more sophisticated control algorithms, will drive efficiency.

One of the discussion points during the session was the use of zirconium oxide (ZrO2) oxygen analyzers to measure the residual oxygen remaining in the flue gases from any combustion process. Ed mentioned the Rosemount Analytical in-situ oxygen transmitter as an example of a zirconium oxide oxygen analyzer to help provide data to better control and optimize the combustion process.

An interesting question came into the panel about the safety considerations of running the combustion process right on the edge at its most efficient but potentially dangerous point. The panel had good thoughts that you need to separate the control aspects from the safety instrumented system burner management aspects. Like any process with safety risks, a risk analysis and risk mitigation strategy per the IEC 61511 international safety standard is critical.