In today’s guest post, Emerson’s Alternative Energy industry group leader, Alan Novak, shares the opportunity that shale gas provides to the U.S. economy and the process manufacturing industries:

A new energy source has emerged and is changing the shape of the manufacturing industry–shale gas.

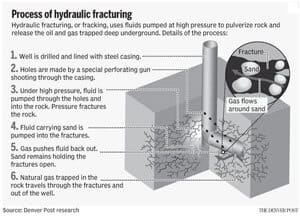

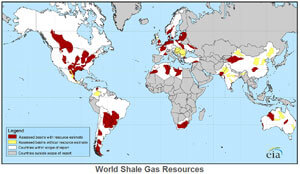

Shale gas, sometimes called “tight gas”, is natural gas that is trapped in rocks underground. It requires a special process, hydraulic fracturing or “fracking“, to release it. Huge reserves of it are located in the US and Canada.

Shale gas is changing the dynamics of both the global energy market and the manufacturing industry since large reserves are located outside of traditional energy supply areas.

Prior to the discovery of shale gas, manufacturers were moving industrial production out of the US to take advantage of cheaper sources of energy elsewhere. Energy intensive industries, such as steel making, and those that use natural gas as a feedstock, such as chemical manufacturing, curtailed new development domestically and in some cases moved entire production plants to other parts of the world.

As US gas supplies have blossomed, we are seeing a gradual reversal of this trend. South African chemical producer Sasol recently announced its intent to build both a new Ethane Cracking unit ($3.5B, for chemical production) and a Gas to Liquids plant ($10B, diesel fuel and chemicals) at its existing location in Louisiana, driven in large part by a ready supply of inexpensive (and plentiful) US shale gas. Sasol is also planning a second Gas to Liquids facility ($10B) in Canada due to large shale gas reserves. And steel producer Nucor is moving ahead with a new Direct Reduced Iron production facility ($750MM) in St. James Parish Louisiana.

What this highlights is that development is closely related to availability of cost-effective energy. All industries that convert raw materials into higher value products require energy and those that are particularly energy intensive (steel and chemical production), will migrate to locations with the most cost effective sources. As the balance of the world energy market shifts with the development of new sources (shale gas), the distribution of manufacturing will shift with it.

The challenge lies in how these resources are developed and the local will to do so. Already, some states in the US are questioning the safety of the fluids used in fracking and have instituted moratoriums on its development.

Shale gas (and oil shale, to be discussed in a subsequent post), presents a tremendous opportunity to not only improve US energy security but to reinvigorate the manufacturing sector.