With the ever-increasing supply of natural gas in the U.S., Emerson’s Alan Novak, leader of the alternative energy industry team, highlights some activity on the demand side.

In previous posts, we have examined the changing dynamics of the global energy supply. New production techniques, such as horizontal drilling and hydraulic fracturing (fracking) of shale, have North America awash in inexpensive natural gas. China may be close behind in developing this resource with oil major Royal Dutch Shell recently signing the first shale gas development agreement.

Even Australia is now eyeing US shale gas as a potential threat to its booming Liquefied Natural Gas (LNG) exports.

So where is all of this natural gas going to go? Traditionally power generation would be the primary use for this fuel but the transportation sector also represents an attractive market. Natural gas can serve as an alternative fuel for transportation in several ways with benefits and challenges for each.

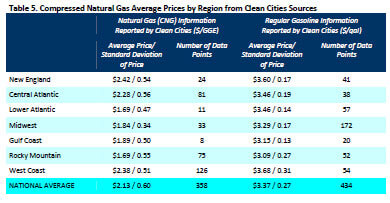

Compressed Natural Gas (CNG). CNG allows converted gasoline vehicles to run on natural gas (some can run both fuels). The gas is compressed to high pressure (3,000 psi) to provide a sufficiently large on board “fuel tank”. The current price of natural gas makes this a very cost effective alternative to gasoline with natural gas currently having a GGE (Gallon Gasoline Equivalent) average price under $2.45/gal across the US (miles per gallon is comparable to gasoline).

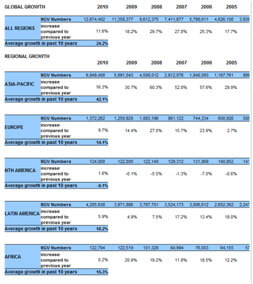

While some US commercial fleets have used CNG for some time, the greatest adoption has been outside of North America. Globally there are approximately 12.5 million natural gas vehicles with only about 124,000 of those in the US.

Most US manufacturers have announced plans to produce CNG fueled trucks while only Honda produces a CNG sedan.

Gas to Liquids (GTL). As Doug Morris mentioned in a previous post, projects are also emerging to convert natural gas to diesel fuel through a process called Gas to Liquids (GTL). Unlike CNG, where natural gas is merely compressed to allow higher density storage, the GTL process converts natural gas to a high-purity diesel or jet fuel, which can be “dropped in” to the existing pipeline and vehicle infrastructure. Although production costs are higher, this fuel can be used without vehicle modification and provides an energy density equivalent to conventional crude oil based jet or diesel while improving the environmental profile. It can also be shipped in conventional tankers.

The primary challenge to GTL adoption is the high capital cost of the production facilities (up to $10B for a 100,000 bbl/day plant) and the need for large volumes of inexpensive natural gas. Crude oil prices above $100/bbl are driving interest in both CNG and GTL.

Time will tell which of these technologies may provide a cost effective alternative to oil in the global transportation system.