Tightening up boiler control strategies and improving the sensing and final control elements not only improves energy efficiency and reduces variability, it can improve overall availability of the boiler as Emerson’s Douglas Morris of the Power and Mining industries explains.

Tube leaks are something that every utility deals with on a regular basis.

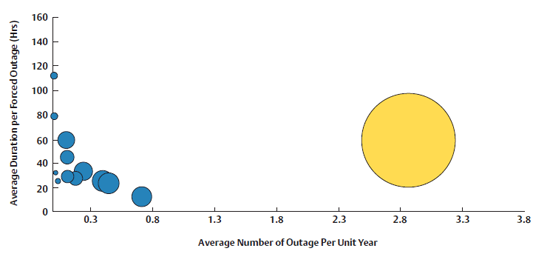

As a matter of fact, when you look at NERC’s [North America Electric Reliability Corporation] Generating Availability Data System (GADS), you’ll find out that boiler tube leaks are the leading cause of forced outages for both coal-fired and combined-cycle plants.

This makes tube leaks the single biggest cause for plant unavailability. To mitigate tube leaks, there are some strategies that can be deployed that address root causes; reheat and superheat temperature variability. These temperature excursions place undue stress on the tubes which can lead to metal fatigue. Simply put, if the boiler is operated with more stable steam temperatures, tube leaks will be fewer, as will the number of forced outages.

To accomplish better temperature control, a boiler gets a solution that is unique to that unit and provides closed loop control recommendations that reduce temperature variability. A side benefit to this solution is that boiler response and ramp rates are often improved, and in the world of renewable power with its variable supply, better fossil unit flexibility and faster ramp rates are always welcomed.

Examples of installed solutions:

- 550MW plant: steam temperature swings taken from +/- 40F to +/- 5F with subsequent reduction in tube leaks and a step change improvement in availability

- 450MW plant: reduced average occurrence of exceeding reheat temperatures by 85%

- 250MW plant: improved ramp rate by 70%

For utilities looking for a cost effective way to improve availability and unit control, perhaps better steam temperature control is a place to start. In fact, the costs associated in this strategy are minimal when compared to the costs associated with a single forced outage for many plants.