Rosemount pressure measurement instrumentation has been part of nuclear power plants’ process automation for more than four decades. The news item from last week, Emerson offers improved safety and performance solutions with new series of nuclear pressure transmitters, shared:

Rosemount pressure measurement instrumentation has been part of nuclear power plants’ process automation for more than four decades. The news item from last week, Emerson offers improved safety and performance solutions with new series of nuclear pressure transmitters, shared:

The Rosemount 3150 Series of Nuclear Pressure Transmitters provides performance improvements in the areas of reference accuracy, transmitter drift, temperature effects, static line pressure effects, and qualified life.

These transmitters meet the latest qualification standards and requirements of third generation plant designs. According to the Wikipedia entry:

A generation III reactor is a development of any of the generation II nuclear reactor designs incorporating evolutionary improvements in design developed during the lifetime of the generation II reactor designs. These include improved fuel technology, superior thermal efficiency, passive safety systems and standardized design for reduced maintenance and capital costs.

The series includes transmitters designed for environments ranging from mild (Rosemount 3152) to severe, harsh environments (Rosemount 3153N and Rosemount 3154N). These transmitters are qualified to IEEE-344 (seismic) and IEEE-323 (environmental) standards. In the U.S., these standards are part of a nuclear power plants’ Equipment Qualification (EQ) Program, which establishes requirements for any equipment installed in the plant.

Emerson’s Christopher Victor presented Enhancing Nuclear Plant Safety: The Rosemount 3150 Series at the recent Emerson Exchange conference in Dallas, Texas.

Emerson’s Christopher Victor presented Enhancing Nuclear Plant Safety: The Rosemount 3150 Series at the recent Emerson Exchange conference in Dallas, Texas.

In his presentation, he explained the role of pressure measurement in safety, efficiency & cost savings, and indirect measurements. Examples of pressure measurement for safety include avoiding pipe and vessel overpressure situations, inputting measurements for safety instrumented functions, and preventing release of harmful process into plant or environment.

Efficiency is helped through accurate measurements to narrow operating range and to keep the process from operating at unnecessary pressures or vacuums. Finally, through differential pressure (DP) measurement, flow and level can be indirectly measured.

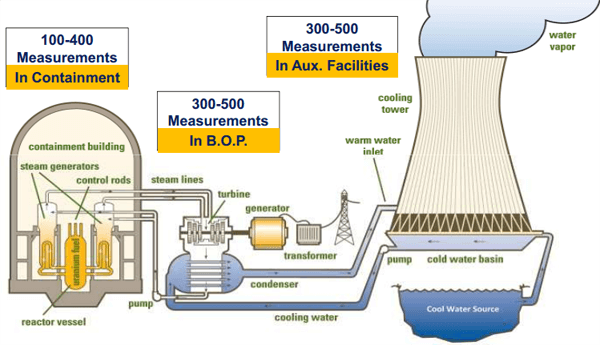

This picture from Chris’ presentation shows some pressure measurements found in a typical nuclear power plant:

Some of the characteristics required for a nuclear application include having 100% analog, radiation hardened electronics. The electronics are proven up to 112 Mrad total ionizing dose (TID) and beyond. By comparison, conventional electronics begin to fail at 1 Krad. A stainless steel, dual-compartment electronics housing provides radiation shielding and acts as a heat sink during a loss of coolant/design basis event (LOCA/DBE). To improve accuracy, the pressure sensor is fully isolated through a hermetically sealed sensor unit enhanced to achieve the seismic standard designs.

Chris closed by noting that these pressure transmitters have been installed in more than 15 countries. The use of Rosemount 3150 Series transmitters in these exceptionally rigorous safety applications continues to grow and to be seen as an industry-leading instrumentation component.