Michalle Adkins

Manager, Life Sciences Consulting

I often get asked, “So, what do you do for a living?” Boy is that a loaded question. When I say that I manage a group of Life Sciences Industry Consultants for Emerson—that really does not help to answer the question.

Hmmm, how do I describe all of this in a few short sentences?

These pharmaceutical and biotech manufacturers are highly regulated by governing bodies, including the Food and Drug Administration here in the United States. It’s critical that these products are manufactured safely and consistently in order to release high-quality products on time and within the licensed processes while maintaining Current Good Manufacturing Practices (cGMP) compliant conditions. Batch-to-batch variability is often the result of aging equipment, lot to lot consistency of input materials, general process variability, and operator inconsistency.

Our team of consultants provide services and tools which manufacturers can use to combat this variability. Decreasing variability can mean faster, release of product, more consistent cycle times, reduction of inventory, and faster time to market for new products.

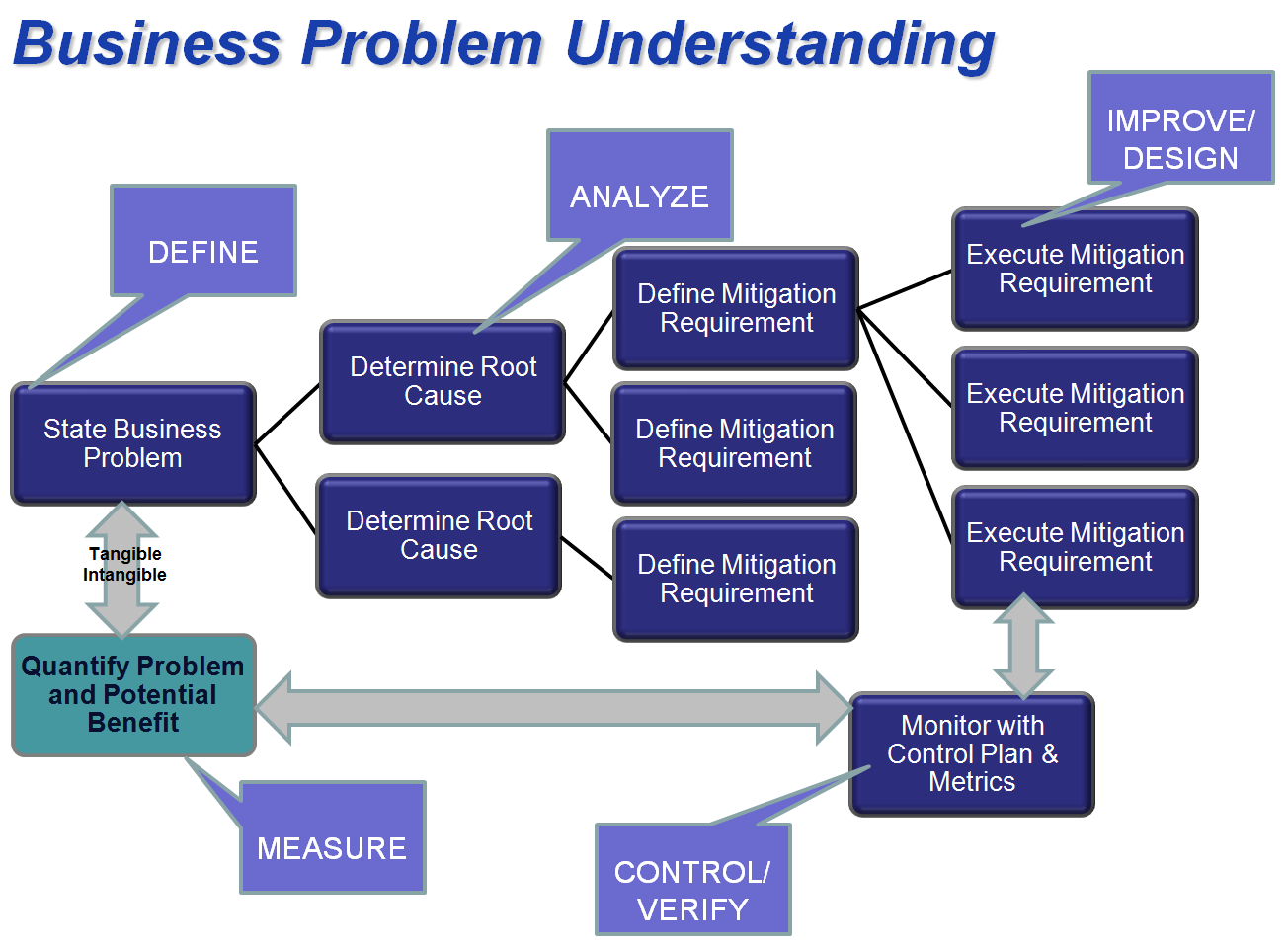

The team helps to solve challenges with compliance, process optimization, process control, and operations management using Lean Six Sigma processes, experiences in the industry, and solutions for integrating the enterprise to the plant floor. Helping solve these challenges translates into inventory reductions, improved reliability, reduced costs, and extended life cycles of production equipment.Process Analytical Technology (PAT) solutions, including Batch Analytics, are enablers to real-time process control of product quality. By measuring some critical quality attributes directly, detecting variability before it becomes a problem, and predicting other critical quality attributes, manufacturers will have a better view of the process and a greater understanding of the parameters needed to maintain efficacy and stability.

To manufacture right the first time, Syncade Operations Management Suite helps manage production workflow, materials, equipment, documents, and training. Common applications in the industry include integrations with enterprise resource planning (ERP) orders and materials; weigh and dispense; electronic batch record execution; as well as document management with or without integrated training management.

By bringing together smart instrumentation such as pH, conductivity, dissolved oxygen, temperature, pressure, flow, level, regulators, and valves with distributed control systems that provide change management, security, machinery health monitoring predictive control, and batch capabilities help maintain GMP compliance and product quality.

All in all, I guess the best answer that I can give to my friends is that my team listens to our customers and provides the solutions to reliably manufacture pharmaceutical and biotech products while minimizing Murphy’s Law so that they can continue to discover and deliver life-changing medications to the world!

From Jim: You can connect and interact with other pharmaceutical and biotech professionals in the Life Sciences track of the Emerson Exchange 365 community.