Gary Mitchell

Senior Industry Consultant – Life Sciences

More and more process manufacturers, including Life Sciences, if not already embracing it, are considering the use of wireless technology in their facilities. Wireless technology can range from wireless networks enabling mobile operators, to equipment monitoring (asset reliability) and wireless instruments (transmitters, valves, etc.)

The increased use of wireless instruments can be credited with improvements in both reliability and battery life, as well as increasing availability and acceptance of new wireless instrument models available, such as radar (level), conductivity and pH transmitters. In addition, some devices now also come with the IEC 62591 WirelessHART communication protocol. Emerson’s Rosemount measurement products even offer a Multivariable Wireless pressure transmitter designed to directly measure two process variables in one installation.One of our major Life Sciences customers is using this Smart Wireless technology to monitor mains and potable (drinking) water usage at its manufacturing plant in Ireland. Installation of wireless flow and pressure transmitters on two new storage tanks has provided an opportunity to test the technology, to better understand water usage throughout the plant and to create a network for cost effectively adding new process instrumentation in the future.

The site is a strategic manufacturing plant that produces a range of bulk active ingredients for use in the formulation of prescription drugs. The existing water storage facility was too small and had no measurement instrumentation in place. Two new storage tanks were installed along with a new pipework infrastructure. The tanks are located around 300 metres from the main control room and there was no existing cabling in place. A wired installation would have required new power and data cables to be buried in trenches. By adopting a wireless solution these significant costs were avoided.

The remote location and non-critical status of the measurements provided an ideal opportunity to install the wireless technology. Because there was no line of sight between the location of the transmitters and the ideal position for the gateway the customer selected the WirelessHART self-organising technology. With self-organising technology, each wireless device can act as a router for other nearby devices, passing messages along until they reach their destination. If there is an obstruction, transmissions are simply re-routed along the network until a clear path to the wireless gateway is found. The technology also offers redundant communication via two or three data routes ensuring the highest possible communication reliability.

Ten Smart Wireless devices were installed including six Rosemount pressure transmitters, two Rosemount flow transmitters and two Rosemount level transmitters. Flow data is transmitted every 30 seconds and pressure and level data every 300 seconds to a wireless gateway strategically positioned on the control room roof. The devices integrate seamlessly with the existing DeltaV distributed control system (DCS) that controls the plant utilities. From here the flow and pressure measurements are sent to a data historian and are available to plant operators for regular monitoring and reporting.

Another example of a major Life Sciences customer embracing this technology involved replacing the instruments on mobile process skids that are frequently moved with wireless devices. This eliminated the requirement for reconfiguration of the control system at each new location. A single wireless network provided 100% reliability in a 5-story building with 12″ reinforced concrete floors. After initial trials, the customer acknowledged that wireless measurements are as reliable as wired instruments, and also recognized reduced engineering and installation (no conduit/wires) costs, as well as room for future expansion by simply adding additional devices.

Further examples of wireless usage in Pharmaceutical and Biotech manufacturing operations include:

- Mobile Operator Stations – using Wi-Fi access points

- Refrigerators/Freezers – recording temperatures without operator rounds, saving hundreds of hours and errors

- Steam Traps – one of the largest energy wastes in facilities can be reduced using wireless acoustic transmitters to detect leaks

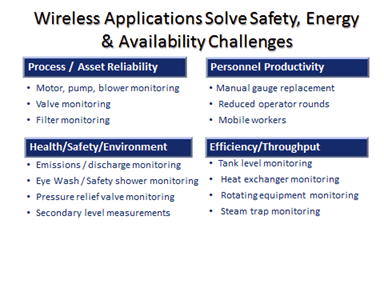

To summarize, wireless technology can be considered for the following applications:

Monitoring: Applications which increase process visibility

Monitoring: Applications which increase process visibility

- Safety: Applications which contain safety features

- Essential Asset Monitoring: Applications providing information about asset itself

- Diagnostics: Reveal additional information about your asset or loop to allow predictive practice

- Slow Loops: Control loops suitable for slow response applications

- Remote or Hard to Reach: Applications which are difficult to instrument with conventional practices

- Manual Replacement: Applications which eliminate the necessity for an operator to be on the plant

- Energy: Reduce energy cost with real-time automated steam trap monitoring

To connect and interact with other Life Sciences and wireless specialists, join the Life Sciences and Wireless tracks in the Emerson Exchange 365 community.