Pharmaceutical and biotech manufacturers face many economic and technical challenges including reduced prices and diminishing profits, rising research & development costs, increasing regulatory requirements and a greater need for optimized manufacturing operations.

Pharmaceutical and biotech manufacturers face many economic and technical challenges including reduced prices and diminishing profits, rising research & development costs, increasing regulatory requirements and a greater need for optimized manufacturing operations.

They note that multiple systems require people and workflows, and:

…the paper batch record is the glue that holds everything together. In this paradigm, these different levels of automation with the paper batch record do not provide optimal, efficient solutions for integrating business data and ensuring data integrity.

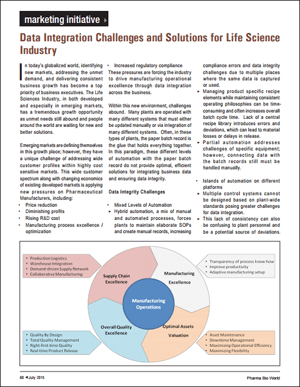

From a data integrity standpoint, challenges stem from mixed levels of automation, islands of automation of different platforms and manual and paper processes.

The mixed levels of automation include manual and automated processes, which force:

…plants to maintain elaborate SOPs and create manual records, increasing compliance errors and data integrity challenges due to multiple places where the same data is captured or used.

Managing recipes can be a source of increased batch cycle time due to:

…errors and deviations, which can lead to material losses or delays in release.

Given these challenges to effective data management, Michalle and Ritesh recommend ways to help in proving compliance, turning data into actionable information and preparing for inspections and audits.

It starts at the base of the information architecture with standards-based smart field devices that are:

…not only responsible for measuring process parameters with required accuracy but also have the capability to share diagnostic information over the same wires.

Manufacturing operations management software, such as Syncade Suite, provides integration:

…to existing SCADA systems or PLCs as well as integration with the DeltaV system…

It also:

…manages process manufacturing operations, providing solutions for material tracking, order management, manufacturing procedure workflow, systems integration and data visualization, and document management.

As these data sources are connected and integrated across the ISA-95 information hierarchy, real-time information and a current electronic batch record becomes available to the decision makers across the manufacturing organization. Errors from manual entries and delays from workflows can be minimized.

Michalle and Ritesh conclude:

In summary, standardized, consistent automation enables better data integrity and solutions for the business that can result in overall business profitability through reduction of errors, streamlined business processes, and constancy throughout the plant.

Read the article for more on some of the important industry standards as well as technologies play assist in the data integration required to optimize manufacturing operations.

You can connect and interact with other pharmaceutical and biotech experts in the Life Sciences group in the Emerson Exchange 365 community.