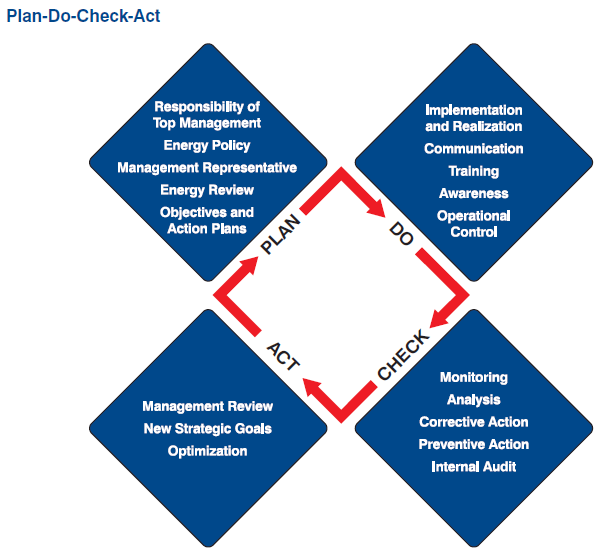

Plan. Do. Check. Act. From Wikipedia:

PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative four-step management method used in business for the control and continual improvement of processes and products. It is also known as the Deming circle/cycle/wheel, Shewhart cycle, control circle/cycle, or plan–do–study–act (PDSA).

The ISO 50001:2011 global energy management standard, modeled after the ISO 9001 Quality Management and ISO 14001 Environmental Management Standards, supports process manufacturers and producers to use energy more efficiently. The ISO 50001 process follows the same PDCA approach as these other ISO standards and provides a framework to:

- Develop a policy for more efficient use of energy

- Fix targets and objectives to meet the policy

- Use data to better understand and make decisions about energy use

- Measure the results

- Review how well the policy works, and

- Continually improve energy management.

Emerson’s Bob Sabin described PDCA as it relates to energy management. He noted that for most plants, improved energy performance also leads to higher reliability, improved availability and lower operational risks from abnormal situations.

A key to success in establishing an effective energy management program is ownership by the top management in the company. This ownership is not just to implement an energy management program or system, but to keep the continuous improvement cycle going over time with committed resources and oversight.

Plan

During the plan phase of the cycle, an energy officer and an energy team should be appointed and the organization needs to formulate the energy policy in form of a written statement, which contains the intent and direction of energy policy. This energy policy should be clearly communicated within the organization. The energy team driving this continuous improvement cycle is the connection between management and employees. In this phase, the organization has to identify the significant energy uses and prioritize the opportunities for energy performance improvement.

Do

The stated objectives and processes are now introduced and implemented. Top management assures that resources are made available and responsibilities determined. Plant staff and other participants must be aware and capable of carrying out their energy management responsibilities. The realization of the energy management system starts.

Check

An energy management system requires a process for compliance and valuation of energy-related objectives. An internal audit can help to verify that the energy management system is functioning properly and generating the planned results.

The processes are monitored with regard to legal and other requirements (customer requirements, internal policies) as well as to the goals of the organization’s energy management program. The results are documented and reported to top management.

The processes are monitored with regard to legal and other requirements (customer requirements, internal policies) as well as to the goals of the organization’s energy management program. The results are documented and reported to top management.

Act

Top management prepares a written valuation based on the internal audit. This document is called the management review. The results will be evaluated on their performance level. If necessary, corrective or preventive actions can be initiated. Energy-relevant processes are optimized and new strategic goals are derived.

A comprehensive 128-page, Sustainable Energy Efficiency guide is available to help you plan, do, check and act on your energy management program. A team of Emerson Industrial Energy consultants can help guide you through the process.

You can also connect and interact with other energy management experts in the Industrial Energy group in the Emerson Exchange 365 community.