At the 2018 Emerson Exchange conference, Emerson’s Bob Sabin and Scott Pettigrew presented, Combustion Control Optimized with Patented Control Configuration. Bob opened describing the Emerson Industrial Energy Consulting group and how they work with manufacturers and producers in many industries about combustion control and optimization.

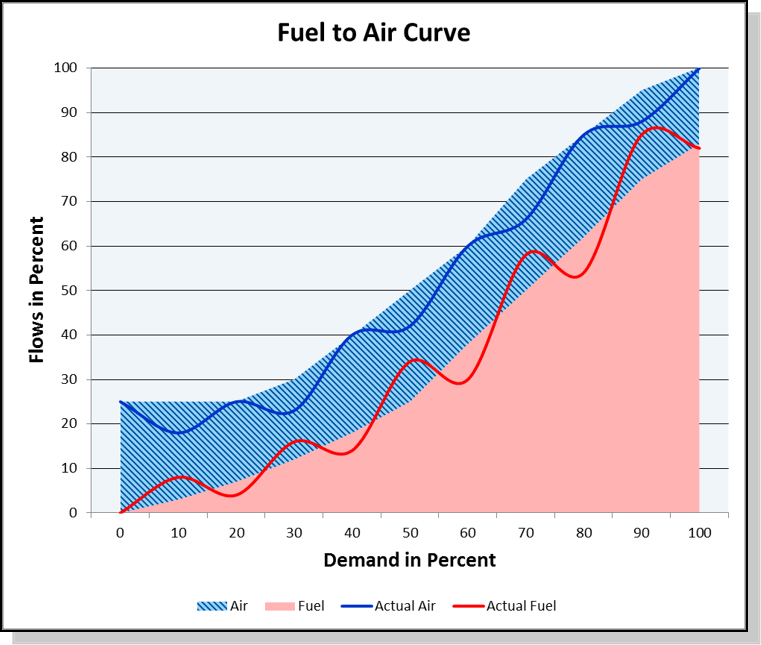

Fuel air curves have been used for decades to control combustion. They are inherently a compromise and control performance can be improved. The curves are determined at one point in time, established by empirical testing of the unit over its load range. Changes in energy input to combustion process is not handled well. And, it’s not possible to substitute on fuel for another on a BTU basis.

Fuel air curves have been used for decades to control combustion. They are inherently a compromise and control performance can be improved. The curves are determined at one point in time, established by empirical testing of the unit over its load range. Changes in energy input to combustion process is not handled well. And, it’s not possible to substitute on fuel for another on a BTU basis.

To improve the performance of an existing unit (boiler, furnace, etc.) you need to build it up from the bottom, first by understanding constraints and next by having accurate, repeatable measurements and final control.

Scott then took us through combustion 101. The steam header pressure is what people use to control the combustion process. To increase header pressure, more fuel and air are added to the combustion process. By using control technology instead of fuel air curves to account for changes in BTUs from the fuel source, the variability can be reduced in controlling the steam header pressure.

He showed an excess air determination spreadsheet to identify the variables added to the DeltaV control strategy as part of the SmartProcess Boiler application. BTU compensation can be measured or unmeasured. By measuring consumed air, inferred heating value is detected using oxygen measurement.

To optimize combustion, Scott noted that it best to push control as low in the architecture as possible—in the control system. Control is done in engineering units and not percentages. There are pressure, flow, and condenser flow modes for boilers, maximizing alternate fuel burning. Part of the combustion process is dynamic excess air control.

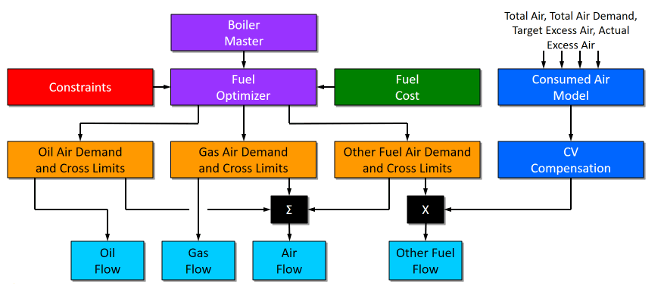

Scott shared an example of a boiler with 5 different fuels each with different BTUs and physical properties. The mix of fuels is optimized around fuel cost to burn the waste fuels first. The fuel optimizer is based on DeltaV PredictPRO model predictive control technology.

The MPC block is the fuel master getting fuel demand from masters and the total heat release fired. The outputs are air demand, waste fuel & cross limits, and fuel oil air & cross limits.

Bob closed with some business results across several industries. The first example was an integrated pulp and paper mill with four boilers who wanted to stop burning coal and switch over to burning bark. The project payed itself back in under a year with biomass increasing by 150% on one of the boilers.

A second example was to reduce steam costs through improved efficiency and increased biomass burning. The solution included a new overfire air system, upgraded control equipment and the SmartProcess Boiler application. Applying this solution resulted in the percentage of steam from biomass increase from approximately 50% to 80% and a reduction in fossil fuel usage of 70%.

The process for unit improvement starts with a performance audit, followed by combustion testing, fuel handing modifications, air system upgrades, measurement improvements, actuation improvements, combustion control strategy development, installation, commissioning & startup and standard operating procedure modifications as needed. Finally measuring the improvements against the initial performance audit provides the return on investment required for any future improvement justifications.

Visit the Industrial Energy & Onsite Utilities section of Emerson.com to learn more about how the Operational Certainty consultants can help improve combustion performance for your facility.