Emerson

Automation Experts

Featured Posts

A Multiphase Flow Meter Developed for The Future April 24, 2025 | Downhole, Flow, Measurement Instrumentation, Oil & Gas Let’s talk about the Roxar 5726 Multiphase Transmitter, an integral part of the Roxar 2600 Multiphase Flow Meter (MPFM). In the first blog of this series, we shared exciting news about the introduction of the Roxar 5726 Multiphase Transmitter and highlighted some key values provided by this innovation. Today, in the fourth and final blog… Read More

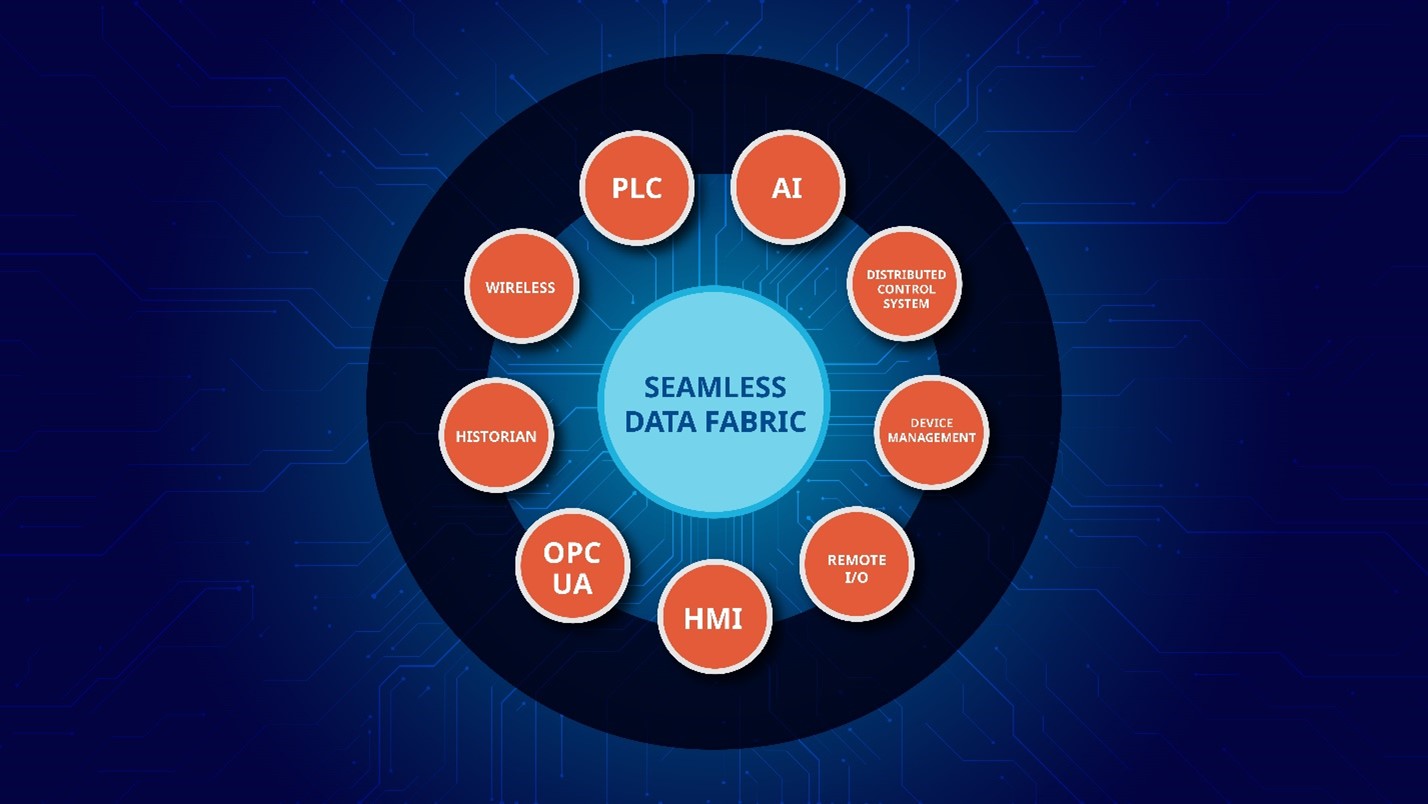

A Multiphase Flow Meter Developed for The Future April 24, 2025 | Downhole, Flow, Measurement Instrumentation, Oil & Gas Let’s talk about the Roxar 5726 Multiphase Transmitter, an integral part of the Roxar 2600 Multiphase Flow Meter (MPFM). In the first blog of this series, we shared exciting news about the introduction of the Roxar 5726 Multiphase Transmitter and highlighted some key values provided by this innovation. Today, in the fourth and final blog… Read More One Platform to Rule Them All April 23, 2025 | Control & Safety Systems, Digital Transformation AI seems to be everywhere these days. It’s on our phones, it interacts with us when we need customer service, it’s generating art and entertainment—the list goes on and on. However, one place where AI tools don’t seem to be making an appearance is at the control level of process manufacturing plants. There’s a… Read More

One Platform to Rule Them All April 23, 2025 | Control & Safety Systems, Digital Transformation AI seems to be everywhere these days. It’s on our phones, it interacts with us when we need customer service, it’s generating art and entertainment—the list goes on and on. However, one place where AI tools don’t seem to be making an appearance is at the control level of process manufacturing plants. There’s a… Read MoreLatest Posts

Enhance Water Management and Utilities in Mining with Emerson’s Innovative Flow Technology

Managing water efficiently is crucial in mining—any uncertainty can lead to elevated costs, safety and environmental risks, and operational inefficiencies. Emerson's advanced flow technologies, including the Flexim Non-Intrusive Ultrasonic Flow Meter and the...

Why Precision in Water Management Matters in Mining

In the mining and metals industry, managing every drop of water is not just an environmental responsibility but a critical economic necessity. Water, in its silent flow, carries the weight of operational efficiencies and sustainability goals. Yet, as our industry...

Elevate Your Maintenance Game: The Power of Smart Positioners and Emerson’s Experts Analysis

During a recent presentation at Emerson Exchange 2025, Daniel Busch, Emerson Senior Valve Condition Monitoring Analyst, and Jordan Cain, Account Manager at Control Southern Inc., presented "Using Smart Positioners to Make Smart Decisions." An attendee asked, "Do you...

Stronger Together: Why Power Industry Cybersecurity Starts with Collaboration

One of the greatest challenges around the world is convincing people (or companies, for that matter) to make changes they don’t want to invest in. Regardless of the state of the marketplace, change that comes with added costs is always a difficult sell. And if that...

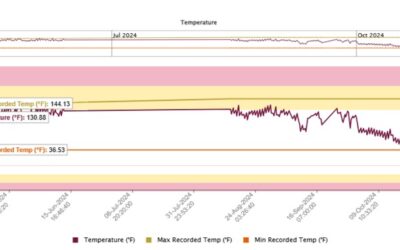

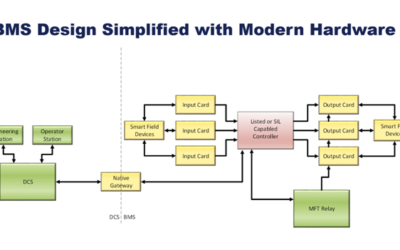

Modern Burner Management Control and Optimization

At the 2025 Emerson Exchange Conference, Emerson’s Steven Kormann and Ross Turner presented “Not Your Grandfather’s Burner Control: Modern BMS Hardware for Modern NFPA Compliance”.

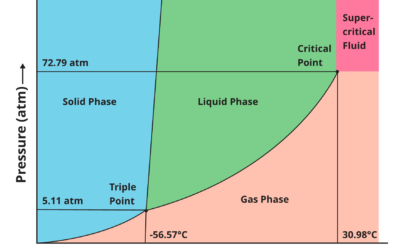

Forging a New Value Chain: Advanced Solutions for Carbon Dioxide Measurement in CCUS

Over the last century and more, a few industries have developed large-scale integrated production and distribution systems, covering the span from source to final consumer. Oil and gas are the most obvious, covering all aspects of industrial, commercial, and consumer...

Meet Our Bloggers & Experts

Jim Cahill

Chief Blogger, Social Marketing Leader

Todd Walden

Author and Blogger

Systems & Software

Erianne Ferrer

Senior Analyst, Social Media

Discrete Automation

Jonas Berge

Senior Director, Applied Technology

Kelly Albano

Marketing Product Manager

Popular Posts

Want to get in touch?

Please do, our experts are here. Contact us so we can continue

the conversation.

Stay up to Date with the Latest News and Updates

Follow Us

We invite you to follow us on Facebook, LinkedIn, X and YouTube to keep up to date on all the latest news, events and innovations to help you take on and solve your toughest challenges.

Want to re-purpose, reuse

or translate content?

Please do, Just link back to the post and drop us a quick email so I can share your work. Thanks!

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.